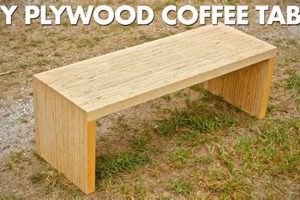

The phrase refers to the process of constructing a low-lying table, suitable for outdoor use, through personal effort rather than purchasing a pre-made item. Such tables often serve as a focal point for seating arrangements on outdoor living spaces. An example involves repurposing salvaged wood and metal components to create a rustic-style surface for beverages and decorative items.

Creating furniture in this manner offers several advantages. It allows for customization to specific dimensions and aesthetic preferences, potentially leading to a more unique and fitting addition to the outdoor environment. Furthermore, it presents an opportunity for cost savings compared to purchasing commercially available alternatives and can reduce waste through upcycling materials. The practice has gained popularity as individuals seek sustainable and personalized home decor solutions.

The subsequent sections will delve into specific design considerations, material selection, and step-by-step instructions for accomplishing a successful project. This will include guidance on choosing weather-resistant materials, implementing appropriate joinery techniques, and applying protective finishes to ensure durability and longevity of the finished product.

Essential Guidelines for Outdoor Table Construction

The following guidelines are designed to enhance the success and longevity of self-constructed outdoor tables.

Tip 1: Material Selection is Paramount: Prioritize materials known for their resistance to environmental factors. Teak, cedar, and redwood offer natural weather resistance. When using other woods, ensure proper treatment with preservatives and sealants.

Tip 2: Secure Joinery Techniques: Employ robust joinery methods, such as mortise and tenon, or pocket hole screws with exterior-grade adhesive. Weak joints will compromise the structural integrity of the table, particularly under outdoor conditions.

Tip 3: Incorporate Adequate Drainage: Design the tabletop with slight gaps or use materials that do not retain water. Standing water can lead to warping, rot, and accelerated deterioration.

Tip 4: Implement a Durable Finish: Apply multiple coats of a high-quality exterior-grade finish, such as marine varnish or spar urethane. This protective layer shields the wood from UV radiation, moisture, and fungal growth.

Tip 5: Consider a Protective Cover: When not in use, safeguard the table with a waterproof cover. This reduces exposure to the elements, further extending the lifespan of the construction.

Tip 6: Proper Fasteners Use stainless steel or coated screws, nails, and bolts for a patio coffee table to prevent rust.

Tip 7: Test before Usage Before actual usage, make sure the DIY patio table surface is levelled. Any adjustments can be made before adding heavier things on it.

Tip 8: Consider the Height Ensure height is suited with your patio chairs or sofa. This prevent over-reaching or slouching.

Adhering to these recommendations will contribute significantly to the creation of a durable and aesthetically pleasing outdoor table that withstands the rigors of prolonged exposure to the elements.

The concluding section will address common challenges encountered during the building process and offer troubleshooting advice to ensure a successful outcome.

1. Durable Material Selection

The longevity and functionality of an outdoor table are inextricably linked to the selection of durable materials. This consideration becomes paramount when undertaking self-construction, as the builder assumes responsibility for ensuring the finished product withstands environmental stressors. Inadequate material selection inevitably leads to premature degradation, structural instability, and ultimately, the need for costly repairs or replacement. For example, using untreated pine for a tabletop directly exposed to rain and sunlight will result in warping, cracking, and rot within a relatively short period.

Proper material choice mitigates these risks. Naturally weather-resistant woods, such as teak, cedar, and redwood, possess inherent oils and compounds that repel moisture, insects, and fungal growth. Alternatively, pressure-treated lumber offers a cost-effective solution for resisting decay, albeit often requiring additional sealing or staining for aesthetic purposes. Furthermore, the selection extends beyond wood. Metal components, such as legs or frames, should be corrosion-resistant; stainless steel or powder-coated aluminum are preferred over untreated steel, which is susceptible to rust.

Therefore, comprehensive research and careful evaluation of material properties are essential components of a successful patio table project. Neglecting this crucial step undermines the entire endeavor, resulting in a structure that fails to provide lasting utility. Investing in appropriate materials translates directly to a more durable, cost-effective, and aesthetically pleasing outdoor furnishing.

2. Weather-Resistant Finish

A weather-resistant finish constitutes a critical component in the creation of a durable outdoor table. This protective layer shields the underlying material, typically wood, from the detrimental effects of prolonged exposure to environmental elements. Without an adequate finish, the structural integrity and aesthetic appeal of the piece are compromised, leading to premature failure.

- UV Protection and Color Retention

Ultraviolet radiation degrades many common materials used in outdoor furniture construction, causing fading, discoloration, and embrittlement. A weather-resistant finish incorporates UV inhibitors that mitigate these effects, preserving the original color and structural integrity of the table. For instance, spar urethane, often used in marine applications, provides excellent UV protection for wooden surfaces. In the absence of this protection, a dark stain could fade to a dull gray within a single season.

- Moisture Barrier and Rot Prevention

Moisture infiltration fosters fungal growth and wood rot, weakening the structure. A quality finish creates a barrier against water absorption, preventing these destructive processes. Consider the application of an exterior-grade oil-based primer followed by two coats of a durable paint; this system minimizes moisture penetration, extending the lifespan of the table. Conversely, a table left unfinished will quickly absorb moisture, leading to warping and decay.

- Abrasion Resistance and Surface Integrity

Outdoor tables are subject to wear and tear from physical contact, accidental impacts, and airborne particles. A durable finish provides a protective layer against abrasion, preventing scratches and maintaining the surface integrity of the table. For example, a two-part epoxy finish creates a hard, scratch-resistant surface suitable for high-traffic outdoor areas. Without such protection, the table’s surface would quickly become marred and unsightly.

- Adhesion and Flexibility

A weather-resistant finish should have good adhesion to the substrate to prevent peeling or cracking. It should also be flexible enough to accomodate the wood’s expansion and contraction as environmental conditions change. A primer, specifically designed for outdoor use, can provide good surface for a strong adhesive and flexible bond of the paint or varnish.

The strategic application of a weather-resistant finish is thus not merely an aesthetic choice but a fundamental requirement for ensuring the longevity and functionality of an outdoor table. The selected finish should be carefully matched to the specific material and intended use of the table, taking into account factors such as UV exposure, moisture levels, and potential physical stresses.

3. Stable Structural Design

Stable structural design is a paramount consideration in the domain of outdoor table construction. A well-designed structure ensures safety, longevity, and continued functionality of the finished piece, particularly in the face of variable environmental conditions. The absence of a structurally sound design can lead to premature failure, posing potential hazards and negating the time and resources invested in the building process.

- Load-Bearing Capacity and Weight Distribution

A primary aspect of stable structural design involves ensuring the table can support anticipated loads without deformation or collapse. This requires careful consideration of material strength, joint integrity, and the overall distribution of weight across the table’s frame. For instance, a table intended to hold heavy objects, such as potted plants or stacks of books, necessitates robust support structures, such as thick legs and reinforced aprons. Insufficient load-bearing capacity can result in sagging, warping, or catastrophic failure, especially under dynamic loads or uneven weight distribution.

- Joint Integrity and Connection Strength

The points where individual components of the table are joined represent critical areas for structural stability. Weak or improperly executed joints can compromise the overall integrity of the structure, leading to instability and eventual collapse. Employing appropriate joinery techniques, such as mortise and tenon joints, dovetail joints, or properly fastened screws with adhesive, is essential for ensuring robust connections. The choice of joinery method should be informed by the specific materials used, the anticipated stresses on the joint, and the desired aesthetic appearance of the table. Furthermore, using screws or nails that are too short or coated improperly for outdoor use may result in rusting and loss of connection strength.

- Resistance to Environmental Forces

Outdoor tables are subjected to a variety of environmental forces, including wind, rain, temperature fluctuations, and direct sunlight. A stable structural design must account for these factors to prevent damage and maintain functionality. For example, a table with a large, unsupported tabletop can act as a sail in strong winds, potentially leading to tipping or structural damage. Designing the table with a low center of gravity, incorporating windbreaks, or securely anchoring it to the ground can mitigate these risks. Similarly, expansion and contraction of materials due to temperature changes can stress joints and lead to cracking or warping. Allowing for slight movement in the design can prevent these issues.

- Material Selection and Compatibility

The choice of materials significantly impacts the structural stability of the finished table. Different materials possess varying strengths, stiffness, and resistance to environmental degradation. Selecting compatible materials and accounting for their individual properties is crucial for ensuring long-term stability. For example, combining a rigid metal frame with a flexible wooden tabletop without proper isolation can lead to stress concentrations and eventual failure of the wooden component. Similarly, using dissimilar metals in close proximity can result in galvanic corrosion, weakening the structure over time. Therefore, careful consideration of material properties and compatibility is essential for achieving a stable and durable outdoor table.

The various facets of stable structural design collectively contribute to the overall robustness and longevity of an outdoor table. Careful consideration of load-bearing capacity, joint integrity, resistance to environmental forces, and material selection ensures a safe, functional, and aesthetically pleasing addition to outdoor living spaces. Neglecting these aspects can lead to a structurally unsound product that requires frequent maintenance or premature replacement, ultimately undermining the value and utility of the self-construction effort.

4. Appropriate Table Height

The dimension from the ground to the table’s surface significantly influences the functionality and ergonomics of a self-constructed outdoor table. The selection of a table’s vertical measurement directly dictates its suitability for various activities, such as holding beverages, supporting reading materials, or serving as a footrest. A patio table that is too high may be awkward to use in conjunction with low-sitting outdoor furniture. Conversely, a table that is excessively low may require users to bend uncomfortably, leading to physical strain. An example includes a table intended to accompany Adirondack chairs; if the table’s surface is positioned significantly below the chair’s seat height, accessing items placed on the table becomes challenging.

In the context of a project, proper height consideration contributes to user comfort and overall satisfaction. The practical significance lies in optimizing the interaction between the table and surrounding seating arrangements. A common guideline suggests positioning the tabletop at a level approximately equal to or slightly below the seat height of the adjacent chairs or benches. This promotes ease of access and prevents strain on the back and arms. Deviations from this guideline should be deliberate and based on specific functional requirements or aesthetic preferences. For instance, a table intended solely for decorative purposes may be designed with a lower profile.

In conclusion, proper table height is a crucial aspect of a well-executed project. It directly impacts the usability and comfort associated with the finished product. Accurate measurement and thoughtful consideration of the intended application are essential for achieving a functional and ergonomically sound design. A project which disregards this aspect risks producing a piece of furniture that detracts from, rather than enhances, the outdoor living space.

5. Surface Drainage

Effective mitigation of water accumulation on the surface constitutes a crucial element in self-constructed outdoor table. The presence of standing water accelerates material degradation, compromises structural integrity, and fosters the growth of undesirable organisms. Consequently, designing for adequate outflow is paramount to ensure longevity.

- Tabletop Gaps and Spacing

Incorporating intentional gaps between individual boards forming the tabletop allows water to readily drain through, preventing pooling. This is particularly relevant when using solid wood planks that are prone to warping or cupping when consistently exposed to moisture. As an example, a tabletop constructed with half-inch gaps between boards minimizes water retention following a rain event. Neglecting to provide such gaps can lead to accelerated deterioration of the wood and subsequent structural weakness.

- Sloping Tabletop Design

A subtle incline built into the tabletop’s surface encourages water to flow towards the edges, facilitating its removal. This approach is suitable for solid-surface tabletops made from materials such as concrete or tile. The slope should be gradual, ideally around one-quarter inch per foot, to avoid creating an uneven surface that interferes with the placement of items. A level surface allows water to accumulate, fostering the growth of mold and algae, and potentially causing staining.

- Material Permeability

The inherent permeability of the tabletop material influences its susceptibility to water damage. Highly porous materials, such as unfinished wood or certain types of stone, readily absorb water, increasing the risk of rot and cracking. Selecting less permeable materials, or applying a sealant, reduces the potential for water absorption. For instance, treating a wooden tabletop with a water-repellent sealant minimizes moisture infiltration, thereby extending the lifespan.

- Drainage Channels and Outlets

Integrating designated drainage channels or outlets directs water away from the tabletop’s surface and minimizes the risk of localized pooling. This design feature is particularly effective for tables with intricate surface patterns or raised edges that can trap water. As an example, small channels routed into the underside of the tabletop can collect and redirect water towards designated drainage points. Omitting such features can lead to prolonged exposure to moisture, accelerating material degradation.

Addressing the drainage considerations outlined above, in relation to the surface of table, is critical to ensuring long term structural integrity. The absence of attention will inevitably lead to problems related to premature decay, with the subsequent requirement for repair or complete replacement, hence undermining the project. In essence, planning for sufficient water runoff is not merely an aesthetic detail, but a functional imperative within the design.

6. Adequate Joint Strength

Within the context of “patio coffee table diy,” the concept of adequate joint strength assumes critical importance. It directly influences the structural integrity, stability, and longevity of the self-constructed furniture piece. The connections binding individual components of the table, such as legs to tabletop or frame to support structure, are subject to continual stress from weight, environmental factors, and general use. Insufficient joint strength is a primary cause of premature failure in outdoor furniture, leading to instability, sagging, or even complete collapse. For example, a table assembled with poorly secured screws and inadequate adhesive will likely become wobbly and unstable within a short period, especially when exposed to the fluctuating temperatures and moisture levels characteristic of outdoor environments.

Achieving appropriate joint strength necessitates careful consideration of joinery techniques, material selection, and fastener types. Common joinery methods include mortise and tenon, dovetail, and rabbet joints, each offering varying degrees of strength and complexity. The selection of a particular technique depends on the skill level of the builder, the available tools, and the desired aesthetic. Regardless of the chosen method, proper execution is crucial. Ensuring tight fits, appropriate adhesive application, and secure fastening are essential for maximizing joint strength. For instance, when using screws, selecting the correct length and type for the specific materials being joined is imperative. Using screws that are too short will result in inadequate holding power, while using screws that are not designed for outdoor use will lead to corrosion and eventual failure.

In summary, adequate joint strength is an indispensable element of a successful table construction. Its significance resides in preventing structural failure and ensuring long-term usability. Through careful planning, precise execution of joinery techniques, and the selection of appropriate materials and fasteners, the project is enabled to withstand the rigors of outdoor use and provide lasting service. Neglecting this vital aspect compromises the entire endeavor, leading to a potentially hazardous and ultimately unsatisfactory outcome.

Frequently Asked Questions

The following section addresses common inquiries and concerns regarding the self-construction of an outdoor table. The information aims to clarify misconceptions and provide practical guidance.

Question 1: What is the most common cause of structural failure in DIY outdoor tables?

Inadequate joint strength is the predominant factor. Insufficiently secured connections between components compromise the overall stability, leading to eventual collapse under stress or environmental exposure.

Question 2: Is it necessary to use weather-resistant lumber, or can ordinary lumber be treated?

Weather-resistant lumber offers inherent protection and extended longevity. Ordinary lumber requires thorough treatment with preservatives and sealants, diligently reapplied at regular intervals, to achieve comparable resistance.

Question 3: How important is drainage in preventing damage to outdoor table surfaces?

Effective drainage is critical. Standing water promotes rot, fungal growth, and material degradation. Designs incorporating gaps, slopes, or drainage channels are essential for preventing water accumulation.

Question 4: What type of finish provides the best protection against UV radiation?

Marine-grade varnishes and spar urethanes are formulated with UV inhibitors, offering superior protection against fading, discoloration, and embrittlement caused by prolonged sun exposure.

Question 5: Is it possible to build a durable outdoor table without specialized woodworking tools?

While specialized tools can enhance precision and efficiency, a functional and reasonably durable table can be constructed with basic hand tools, provided that careful attention is given to accurate measurements and secure assembly techniques.

Question 6: What is the ideal height for an outdoor table intended for use with standard patio chairs?

The optimal height typically ranges from 16 to 18 inches, allowing for comfortable access and interaction with users seated in standard patio chairs. Deviations from this range should be based on specific design considerations or user preferences.

In essence, durability, weather resistance, and structural integrity should dictate the table construction process. Each detail must be considered.

The subsequent article segment will offer advice on common blunders to avoid during the self-construction journey.

Crafting a Resilient Outdoor Centerpiece

The preceding discourse elucidated the complexities inherent in, emphasizing the critical elements that contribute to a durable and aesthetically pleasing outcome. Material selection, joint integrity, surface drainage, protective finishes, and appropriate dimensions were explored as determinants of structural soundness and longevity. Proper consideration of these factors is paramount, mitigating the risks of premature failure and ensuring sustained utility in outdoor environments.

The success or failure of a self-constructed outdoor table hinges on the meticulous application of sound engineering principles and a thorough understanding of material properties. Prudent planning, careful execution, and a commitment to quality craftsmanship represent the pillars of a project that not only enhances the aesthetic appeal of outdoor living spaces but also provides enduring functionality. The endeavor requires diligence and precision, in pursuit of a valued addition to the exterior. The design must also have functional use to be more efficient.