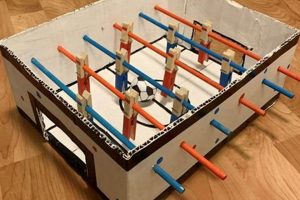

The crafting of a personalized surface for placement of beverages and other items within a living space through individual effort is the core concept. This process typically involves utilizing existing materials, repurposing discarded items, or purchasing new components to construct a functional and aesthetically pleasing furniture piece. An example includes transforming a reclaimed wooden pallet into a rustic furnishing by cleaning, sanding, and applying a protective finish, then attaching legs.

This form of creative construction offers several advantages. Economically, it presents a cost-effective alternative to purchasing manufactured furniture. Environmentally, it promotes sustainability by reducing waste through repurposing and utilizing recycled materials. Historically, the desire for customized furnishings predates mass production, reflecting a return to individual craftsmanship and personalized home decor. The practice fosters creativity and allows for the creation of a unique item tailored to specific spatial and stylistic requirements.

The subsequent discussion will address common construction techniques, material selection considerations, and design ideas applicable to this type of project, enabling the reader to undertake such a home improvement endeavor with confidence and achieve a satisfactory outcome.

Guidance for Custom Furnishing Creation

The following recommendations aim to enhance the execution of self-directed surface construction projects, ensuring durability, aesthetic appeal, and functional suitability within a domestic setting.

Tip 1: Material Selection is Paramount: Prioritize durable and structurally sound materials. For wooden surfaces, hardwoods such as oak or maple offer superior resistance to wear and tear compared to softwoods. When repurposing items, thoroughly inspect for damage or instability.

Tip 2: Accurate Measurement and Planning are Crucial: Before commencing construction, meticulously measure the intended space and create a detailed blueprint. This proactive step minimizes errors, reduces material waste, and ensures the finished item fits seamlessly within the environment.

Tip 3: Secure Fastening Techniques are Essential: Employ appropriate fasteners for the chosen materials. Screws provide greater holding power than nails, especially for joining heavy or load-bearing components. Pre-drilling pilot holes prevents wood splitting and ensures a stronger connection.

Tip 4: Protective Finishes Extend Longevity: Apply a sealant or finish to protect the surface from moisture, stains, and scratches. Polyurethane is a durable and water-resistant option suitable for high-traffic areas. Consider the aesthetic impact of different finishes, such as matte, satin, or gloss.

Tip 5: Proper Sanding Promotes a Smooth Surface: Sand all surfaces thoroughly before applying any finish. Start with a coarse grit sandpaper to remove imperfections, then gradually progress to finer grits for a smooth, even texture. Remove sanding dust completely before proceeding.

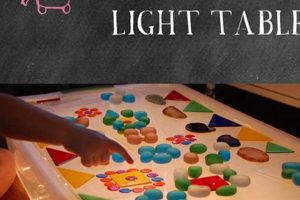

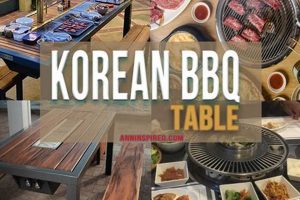

Tip 6: Consider Functionality During Design: Integrate features that enhance usability, such as shelves, drawers, or storage compartments. These additions can maximize the item’s utility and contribute to a more organized living space.

Tip 7: Safety Protocols are Non-Negotiable: Always wear appropriate safety equipment, including eye protection and gloves, when cutting, sanding, or applying finishes. Work in a well-ventilated area to avoid inhaling harmful fumes.

These suggestions underscore the importance of careful planning, material selection, and execution. By adhering to these principles, individuals can create durable and visually appealing furniture pieces that reflect their personal style and enhance their living environment.

The subsequent section will delve into specific design ideas, offering inspiration and practical guidance for creating unique and personalized furnishings.

1. Materials selection

The selection of appropriate materials is fundamental to the successful creation of a personalized surface for placement of beverages and other items. The chosen materials dictate not only the aesthetic character of the piece but also its structural integrity, longevity, and suitability for its intended function within a domestic setting.

- Wood Species and Characteristics

The selection of wood species significantly impacts both the appearance and durability. Hardwoods, such as oak, maple, and cherry, offer superior resistance to scratches, dents, and wear compared to softwoods like pine or fir. Reclaimed wood provides a rustic aesthetic and promotes sustainability, but requires careful inspection for structural integrity and potential contaminants. The wood’s grain pattern, color, and density also contribute to the overall visual appeal and should align with the intended design.

- Metal Components and Fasteners

Metal components, such as legs, frames, and decorative accents, contribute to the structural support and aesthetic style. Steel provides strength and stability, while aluminum offers lightweight corrosion resistance. The choice of fasteners, including screws, bolts, and adhesives, is critical for secure assembly. Fastener selection should be based on the materials being joined and the anticipated load-bearing requirements. Corrosion-resistant fasteners are essential for surfaces exposed to moisture or outdoor conditions.

- Surface Finishing Materials

Surface finishing materials, including stains, paints, varnishes, and sealants, protect the surface from moisture, stains, and scratches while also enhancing its appearance. The selection of finish depends on the desired aesthetic effect, level of protection required, and ease of application. Oil-based finishes offer durability and a rich color, while water-based finishes are environmentally friendly and easy to clean. Proper application techniques are crucial for achieving a smooth and even finish.

- Alternative Material Options

Beyond traditional wood and metal, alternative materials such as glass, stone, concrete, and epoxy resin can be incorporated to create unique and visually striking pieces. Glass provides a sleek and modern aesthetic, while stone offers durability and a natural texture. Concrete can be molded into various shapes and provides a robust, industrial look. Epoxy resin can be used to create decorative inlays and add a touch of artistry. The use of alternative materials requires specialized tools and techniques, but can result in distinctive and personalized creations.

The meticulous selection of appropriate material is key to crafting a piece that is both aesthetically pleasing and functionally robust. Careful consideration of factors such as durability, aesthetic appeal, and compatibility ensures the surface becomes a valuable and lasting addition to the living space. Examples include utilizing durable materials for high-traffic areas and emphasizing visual cohesion with a cohesive color scheme, that enhance the intended aesthetic style for a living room.

2. Design blueprint

A meticulously crafted design blueprint serves as the foundational element for successful surface construction projects. It provides a comprehensive visual representation of the intended outcome, ensuring dimensional accuracy, structural integrity, and aesthetic coherence throughout the construction process.

- Dimensional Specifications and Spatial Considerations

The blueprint delineates precise measurements of all components, including length, width, and height. It also incorporates spatial considerations, ensuring the finished piece fits harmoniously within the designated area. Accurate dimensional specifications prevent misalignment, reduce material waste, and optimize the overall functionality within the living space. An example involves creating a scaled drawing of the living room to ensure the intended piece does not obstruct traffic flow or overwhelm the existing furniture arrangement.

- Material Allocation and Component Breakdown

The design specifies the types and quantities of materials required for each component. It provides a detailed breakdown of individual parts, facilitating accurate material procurement and minimizing the risk of shortages during construction. This aspect is crucial for cost management and efficient project execution. An example of this could be precisely quantifying the amount of wood needed for each leg or shelf, reducing material wastage.

- Assembly Procedures and Structural Details

The blueprint outlines the step-by-step assembly procedures, detailing the sequence of construction and the methods of joining components. It includes structural details, such as the placement of supports, reinforcements, and fasteners, ensuring the stability and load-bearing capacity of the finished item. This facet is paramount for safety and longevity. The design details could describe specific joinery techniques like mortise and tenon for optimal strength and a seamless appearance.

- Aesthetic Elements and Finishing Techniques

The design incorporates aesthetic elements, such as the shape, style, and color scheme. It specifies the intended finishing techniques, including staining, painting, or sealing, to enhance the visual appeal and protect the surface from damage. The blueprint functions as a visual guide, ensuring the finished piece aligns with the intended design vision. Specific details could include specifying the color of the finish to match existing room accents, like the room carpet.

The comprehensive design blueprint streamlines the creation process, mitigating potential errors and optimizing resource utilization. By serving as a visual guide and a detailed roadmap, it empowers individuals to create personalized surfaces that seamlessly integrate into their living space, embodying both functionality and aesthetic appeal. The connection of all elements creates a comprehensive design for the surface and enhances the overall DIY process and end result.

3. Structural Integrity

The structural integrity of a self-constructed surface for the placement of beverages and other items directly determines its functionality, safety, and longevity. Insufficient structural design leads to instability, potential collapse under load, and premature failure, rendering the piece unusable or even hazardous. Examples of inadequate structural considerations include using excessively thin materials for the tabletop, failing to adequately reinforce joints, or neglecting to account for the weight distribution of items placed upon it. The consequence of these errors is often manifested as sagging, wobbling, or complete structural failure.

Ensuring structural integrity necessitates careful planning and execution. The selection of appropriate materials, based on their load-bearing capacity and resistance to stress, is paramount. Employing robust joinery techniques, such as mortise and tenon joints or the proper use of screws and adhesives, strengthens the connections between components. Reinforcement strategies, including the addition of aprons, stretchers, or internal supports, enhance stability and prevent deformation. These design choices collectively contribute to a stable and durable piece, capable of withstanding normal use and environmental factors.

In summary, structural integrity is a non-negotiable aspect of successful surface construction. It necessitates a thorough understanding of materials properties, sound engineering principles, and meticulous construction techniques. Neglecting this critical dimension compromises the safety, functionality, and overall value of the finished piece, highlighting the importance of prioritizing structural soundness throughout the entire project lifecycle. Successful implementation enables the creation of a lasting and reliable furnishing.

4. Finishing techniques

The application of finishing techniques to self-constructed surfaces enhances both their aesthetic appeal and protective qualities. This process involves treating the exterior of the assembled piece to impart a desired visual appearance, provide resistance to environmental factors, and extend its lifespan.

- Surface Preparation: Sanding and Cleaning

Prior to the application of any finishing material, thorough surface preparation is essential. Sanding removes imperfections, such as scratches, dents, and unevenness, creating a smooth and uniform base. Cleaning removes dust, dirt, and oils that could interfere with the adhesion of the finish. For example, using progressively finer sandpaper grits on a wooden surface ensures a smooth and even application of stain or varnish. Failure to properly prepare the surface results in an uneven finish with visible imperfections.

- Staining and Coloring: Enhancing Natural Grain

Stains and coloring agents enhance the natural grain patterns of wood and impart a desired hue. Stains penetrate the wood fibers, altering the color without obscuring the grain. Application methods vary, including brushing, wiping, and spraying. For example, applying a dark walnut stain to a reclaimed wooden surface can accentuate the rustic character and create a visually appealing contrast. Incorrect stain application leads to blotchiness or uneven color distribution.

- Protective Coatings: Varnishes, Lacquers, and Polyurethanes

Protective coatings, such as varnishes, lacquers, and polyurethanes, provide a durable barrier against moisture, scratches, and UV radiation. These coatings form a protective layer on the surface, extending the item’s lifespan and maintaining its aesthetic appearance. For example, applying several coats of polyurethane to a wooden surface creates a water-resistant and scratch-resistant finish suitable for frequent use. Insufficient or improper application of protective coatings results in premature wear and damage.

- Specialty Finishes: Distressing, Antiquing, and Texturing

Specialty finishes, such as distressing, antiquing, and texturing, create unique visual effects and add character to the completed piece. Distressing involves intentionally damaging the surface to simulate wear and tear, creating a vintage aesthetic. Antiquing involves applying glazes or washes to highlight details and create a sense of age. Texturing involves adding tactile elements to the surface, such as raised patterns or rough textures. For example, distressing a newly constructed wooden surface and applying a crackle finish can create a rustic and aged appearance. Incorrect application of specialty finishes results in an unconvincing or artificial appearance.

The selection and application of appropriate finishing techniques are crucial for the successful completion of self-constructed surfaces. These techniques not only enhance the aesthetic appeal but also provide essential protection, extending the lifespan of the item and ensuring its continued functionality within the intended environment. From surface preparation and staining to applying protective coatings and specialty finishes, each step contributes to the overall quality and durability of the finished product.

5. Spatial harmony

Achieving spatial harmony within a living environment is intrinsically linked to the design and execution of furniture construction projects. The creation of a surface designed for beverage or other item placement, when undertaken as a self-directed endeavor, necessitates meticulous consideration of the existing spatial dynamics. A disregard for spatial harmony undermines the functional utility and aesthetic appeal, leading to a disrupted flow and visual imbalance within the room. The dimensions, form, and material choices must complement the surrounding elements, including existing furniture, wall colors, and overall architectural style. An oversized piece in a small room impedes movement and creates a sense of confinement. A design that clashes with the existing dcor disrupts the visual coherence, resulting in an unharmonious environment. Therefore, spatial harmony becomes a guiding principle in the design phase, influencing every decision from material selection to the final finishing touches.

Practical application of this understanding requires careful measurement and analysis of the intended space. A detailed floor plan, incorporating existing furnishings, allows for accurate determination of appropriate dimensions. The consideration of traffic patterns ensures unimpeded movement around the newly constructed surface. Visual analysis of the room’s existing color palette and design style informs material choices and finishing techniques. For example, a minimalist room might benefit from a surface with clean lines and neutral tones, while a more rustic setting might accommodate a piece constructed from reclaimed wood with a distressed finish. The integration of storage solutions can further enhance spatial harmony by reducing clutter and maximizing available space. Success is measured by the extent to which the piece seamlessly integrates into the room, enhancing its functionality and visual appeal.

In conclusion, the pursuit of spatial harmony is not merely an aesthetic consideration but a fundamental component of successful furniture construction projects. It requires a holistic approach that considers the interconnectedness of all elements within the living environment. Challenges include balancing individual design preferences with the constraints of the existing space and achieving a cohesive aesthetic that reflects the user’s personal style. By prioritizing spatial harmony, individuals can create furniture that not only serves its intended function but also contributes to a more balanced, functional, and aesthetically pleasing living space.

6. Functional addition

The integration of functional additions into self-constructed surfaces represents a pivotal consideration in the realm of do-it-yourself projects. This aspect transcends mere aesthetic modifications; it encompasses the incorporation of features that enhance the item’s utility and optimize its contribution to the surrounding environment. Therefore, the successful creation hinges not only on visual appeal but also on its practical usability. The omission of considerations relating to functional additions effectively diminishes the overall value and utility, relegating it to a purely decorative role. A surface lacking storage, for example, represents a missed opportunity to declutter the living space, a primary objective of many furnishing projects.

Practical applications of functional additions manifest in various forms. The incorporation of drawers or shelves provides storage for magazines, remote controls, or other items commonly used in living areas. The inclusion of casters or wheels increases mobility, facilitating easy relocation for cleaning or rearranging furniture. A lifting mechanism transforms the surface into a workspace or dining area, maximizing its utility in smaller living spaces. Integrated power outlets or USB ports enhance the item’s compatibility with modern electronic devices. These design choices, driven by the pursuit of functional addition, elevate the from a mere surface to a versatile and adaptable piece of furniture.

In summary, the strategic implementation of functional additions constitutes a critical element in surface construction. It transforms a visually appealing object into a practical asset, optimizing its contribution to the living environment. Overlooking these considerations limits the item’s potential, reducing its overall value and utility. A well-designed surface incorporates functional additions that seamlessly integrate into the design, providing tangible benefits and enhancing the user’s experience. Thus, a focus on functional enhancement is essential in the successful and valuable creation of a piece of furniture.

7. Cost effectiveness

The economic advantage inherent in self-directed furniture construction, specifically related to a surface designed for beverage placement, represents a primary motivator for many individuals. The potential for significant cost reduction compared to purchasing commercially manufactured items warrants detailed examination.

- Material Sourcing and Acquisition

Material acquisition strategies directly impact project expenses. Reclaimed or repurposed materials, often available at minimal cost or free, provide a sustainable and economical alternative to purchasing new components. The sourcing of materials from salvage yards, online marketplaces, or personal inventories drastically reduces overall expenditures. Conversely, the selection of high-end or specialty materials escalates costs, potentially diminishing the project’s economic advantage. The use of materials at hand is paramount to consider when thinking about cost effective creation.

- Labor Cost Avoidance

The elimination of labor costs constitutes a significant source of savings. By undertaking the construction process independently, individuals avoid the expenses associated with professional furniture assembly or custom fabrication services. This self-reliance requires an investment of personal time and effort but translates into a substantial reduction in overall project costs. Professional labor fees typically constitute a significant portion of the total expense of commercially manufactured furniture.

- Tool Investment Considerations

While self-directed construction avoids labor expenses, it may necessitate an initial investment in tools. The extent of this investment depends on the complexity of the project and the existing tool inventory. Basic projects may require only essential hand tools, while more intricate designs may necessitate power tools, such as saws, drills, and sanders. The long-term value of tool ownership must be weighed against the immediate cost, recognizing that these tools can be utilized for subsequent projects, thereby amortizing the initial investment.

- Customization vs. Mass Production Premiums

Commercially produced items often incorporate design elements or materials that cater to mass appeal, potentially necessitating modifications or upgrades to meet individual preferences. Self-directed construction allows for complete customization, eliminating the need for costly alterations to pre-fabricated furniture. This control over design and material selection ensures alignment with individual aesthetic preferences and functional requirements, providing economic value by avoiding post-purchase modifications.

The attainment of cost effectiveness in surface construction necessitates a holistic approach, encompassing strategic material sourcing, labor cost avoidance, and judicious tool investment. The ability to customize the piece eliminates the premiums associated with mass-produced items, further enhancing the economic appeal of self-directed construction. In conclusion, the combination of all these factors, ensures substantial cost savings compared to purchasing commercially manufactured pieces, particularly when reclaimed materials are used, emphasizing thoughtful design, that ensures a budget friendly end-product.

Frequently Asked Questions

The following addresses common inquiries regarding the planning, execution, and optimization of self-directed construction projects, specifically concerning surfaces designed for beverage placement.

Question 1: What are the essential tools for a basic project?

A basic project necessitates a measuring tape, hand saw, drill with assorted bits, sandpaper (various grits), safety glasses, and a selection of fasteners (screws, nails). Additional tools, such as a power sander or circular saw, enhance efficiency but are not strictly essential for simpler designs.

Question 2: What types of wood are most suitable?

Hardwoods, such as oak, maple, and cherry, offer superior durability and resistance to wear compared to softwoods like pine or fir. Reclaimed wood provides a sustainable option, but requires careful inspection for structural integrity and potential contaminants.

Question 3: How can a durable finish be achieved?

Proper surface preparation, including thorough sanding and cleaning, is crucial. Multiple coats of a high-quality varnish or polyurethane, applied according to the manufacturer’s instructions, provide a durable and water-resistant finish. Consider using an oil-based finish for increased durability in high-traffic areas.

Question 4: How is structural integrity ensured?

Structural integrity is achieved through careful planning, the selection of appropriate materials, and the use of robust joinery techniques. Reinforcements, such as aprons or stretchers, enhance stability and prevent deformation. Accurate measurements and precise assembly are paramount for a structurally sound outcome.

Question 5: How can costs be minimized?

Cost reduction is achieved through strategic material sourcing, utilizing reclaimed or repurposed items, and avoiding unnecessary embellishments. Careful planning and accurate measurements minimize material waste. Tool sharing or borrowing reduces the need for extensive tool purchases.

Question 6: What safety precautions should be observed?

Safety precautions include wearing safety glasses to protect the eyes, using gloves to protect the hands, and working in a well-ventilated area when applying finishes. Always follow the manufacturer’s instructions for the safe operation of power tools. Secure the work piece to prevent movement during cutting or sanding.

These responses provide foundational guidance for individuals embarking on self-directed construction. Diligent adherence to these principles contributes to a successful and rewarding project outcome.

The subsequent discussion will delve into advanced design considerations and innovative techniques applicable to specialized projects.

Conclusion

The preceding exploration of coffee table diy has illuminated its multifaceted nature, encompassing design principles, material selection, structural considerations, and economic implications. The creation of personalized surfaces for beverage placement, through individual effort, presents both opportunities and challenges. Successful execution demands careful planning, meticulous craftsmanship, and a comprehensive understanding of the factors that influence structural integrity, aesthetic appeal, and functional utility.

The potential for cost savings, coupled with the ability to customize furniture to precise specifications, underscores the enduring appeal of coffee table diy. The pursuit of self-directed construction serves not only to create functional objects but also to foster creativity, resourcefulness, and a deeper appreciation for the craft of furniture making. Continued exploration of innovative techniques and sustainable practices will further enhance the value and relevance of this endeavor in the future, encouraging individuals to engage in the rewarding process of crafting their own furnishings.