The construction of a customized home beverage station, frequently utilizing lumber as the primary material, presents an opportunity for personalized design and space optimization. Such projects encompass a range of structural configurations, from simple countertop extensions to elaborate, multi-tiered installations. These projects typically involve careful measurement, precise cutting, and secure joining of wooden components to create a functional and aesthetically pleasing area for mixing and serving drinks.

The value of creating a bespoke social area within a residence resides in its capacity to reflect individual tastes and enhance the home’s overall ambiance. Historically, home bars have served as gathering places, fostering social interaction and entertainment. A self-made version offers cost savings compared to purchasing pre-fabricated units, allows for greater control over material selection, and provides a sense of accomplishment upon completion. Furthermore, such a construction can be tailored to fit specific spatial constraints and storage requirements, increasing the efficiency and usability of the designated area.

Subsequent sections will delve into the specifics of material selection, design considerations, construction techniques, and finishing methods relevant to the successful completion of a customized lumber-based social station project. These elements are crucial to ensuring a durable, attractive, and functional addition to any home.

Essential Construction Guidance

The following guidelines offer critical insights for the successful creation of a customized lumber-based home beverage station. Adhering to these points will contribute significantly to the project’s structural integrity, aesthetic appeal, and overall functionality.

Tip 1: Material Selection: Prioritize the use of kiln-dried lumber to minimize warping or cracking after construction. Hardwoods, such as oak or maple, offer greater durability compared to softwoods, such as pine, particularly for surfaces subject to heavy use.

Tip 2: Precise Measurement and Cutting: Accurate dimensions are crucial. Employ a measuring tape, level, and square to ensure accurate cuts. A miter saw provides the most precise angles for joining pieces.

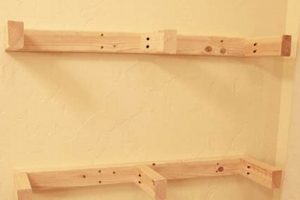

Tip 3: Secure Joinery Techniques: Utilize strong joinery methods, such as mortise-and-tenon, dovetail, or pocket-hole joinery, to create stable connections between lumber components. Consider using wood glue in conjunction with mechanical fasteners for enhanced strength.

Tip 4: Adequate Structural Support: If the design includes an overhang, ensure sufficient support is provided through the use of corbels, brackets, or additional legs. Calculate load-bearing capacity to prevent sagging or collapse.

Tip 5: Surface Preparation and Finishing: Thoroughly sand all lumber surfaces to create a smooth base for finishing. Apply a high-quality sealant or varnish to protect the wood from moisture and stains. Consider multiple coats for enhanced protection.

Tip 6: Ergonomic Design Considerations: Determine optimal countertop height based on intended use. Ensure sufficient legroom is provided if seating is planned. Consider the placement of storage and appliances for ease of access.

Tip 7: Code Compliance: Verify that the project adheres to local building codes, particularly regarding electrical wiring and plumbing, if applicable. Obtain necessary permits prior to commencing construction.

These recommendations emphasize the importance of meticulous planning, precision execution, and adherence to best practices in lumber construction. Successfully implementing these strategies will lead to a robust and visually appealing addition to any home.

The final section will provide insights into design styles and creative customization options for individualized expression.

1. Wood Selection

Wood selection is a critical initial step in the construction of a customized home beverage station. The choice of lumber significantly influences the structure’s durability, aesthetics, and overall functionality. Thoughtful consideration of various wood properties is paramount to a successful build.

- Durability and Longevity

The inherent hardness and resistance to wear of selected wood directly impact the lifespan of the finished station. Hardwoods, such as oak, maple, or walnut, provide superior durability compared to softwoods like pine or fir, particularly for high-use surfaces. Inadequate wood selection can lead to premature wear, scratches, and dents, requiring frequent repairs or replacements.

- Aesthetic Qualities and Visual Appeal

The grain pattern, color, and texture of the chosen wood contribute substantially to the visual appearance. Different wood species offer distinct aesthetic characteristics, ranging from the straight, clean lines of maple to the rich, dark tones of walnut. The selection should align with the desired style of the space and complement existing dcor. Mismatched wood types can detract from the overall aesthetic cohesiveness.

- Workability and Ease of Construction

Some woods are easier to work with than others, impacting the ease and efficiency of the construction process. Softer woods are generally easier to cut, shape, and sand, but may require more care to avoid damage. Hardwoods, while more durable, can be more challenging to work with, requiring specialized tools and techniques. Balancing workability with desired durability is key.

- Moisture Resistance and Stability

The ability of the wood to withstand moisture fluctuations is crucial, particularly in environments prone to spills or humidity. Woods with high natural oil content, such as teak or cedar, offer inherent moisture resistance. Untreated woods can warp, crack, or rot when exposed to moisture, compromising the structural integrity and appearance. Proper sealing and finishing are essential to mitigate moisture-related issues.

The interconnectedness of these facets highlights the importance of informed wood selection for any custom-built beverage station. Choosing the appropriate material based on durability, aesthetics, workability, and moisture resistance will ultimately determine the long-term success and satisfaction derived from the project. For example, while pine may be cost-effective and easy to work with for the frame, a hardwood countertop provides the resilience required for regular use.

2. Design Planning

Design planning constitutes a foundational element in the successful execution of a customized lumber-based home beverage station. This phase dictates the structure’s functionality, aesthetic coherence, and spatial integration. Insufficient planning inevitably leads to suboptimal outcomes, potentially resulting in structural weaknesses, inefficient use of space, and a compromised overall aesthetic. The iterative process of design planning, therefore, represents a critical investment that significantly influences the final product.

Effective design planning encompasses several key considerations. Firstly, spatial assessment is paramount. The available area must be meticulously measured to determine the maximum dimensions of the station. This ensures that the structure integrates seamlessly into the existing environment without impeding traffic flow or compromising existing furniture arrangements. Secondly, functional requirements must be clearly defined. Does the design necessitate built-in refrigeration, specialized storage for glassware, or specific mixing apparatus? Addressing these needs during the planning phase allows for the incorporation of appropriate features and dimensions. A poorly planned design may lack sufficient storage or fail to accommodate necessary appliances, resulting in functional limitations. Consider, for example, a design that fails to account for the depth of a standard-sized wine cooler; the subsequent installation would necessitate costly modifications or a complete redesign.

In conclusion, the connection between design planning and the realization of a customized lumber-based home beverage station is direct and irrefutable. Design planning mitigates potential construction errors, optimizes spatial utilization, and ensures functional alignment with the intended purpose. Neglecting this initial phase compromises the project’s overall integrity and ultimately diminishes its value. Meticulous planning, therefore, is not merely a preliminary step but an indispensable component of a successful build.

3. Accurate Construction

Accurate construction is an indispensable element in the creation of a durable, functional, and aesthetically pleasing home beverage station using lumber. Precise execution directly influences the structural integrity, stability, and overall longevity of the build. Errors in construction can compromise safety, reduce functionality, and detract from the visual appeal of the finished product.

- Dimensional Precision

Dimensional precision is crucial in ensuring that all components of the lumber-based station fit together correctly and function as intended. Inaccurate measurements, cuts, or joinery can lead to gaps, misalignment, and structural weaknesses. For example, if the lumber intended for the frame is not cut to the specified dimensions, the resulting structure may be unstable or unable to accommodate intended shelves or features.

- Secure Joinery Techniques

The selection and application of appropriate joinery techniques are essential for creating robust connections between lumber components. Weak or poorly executed joints can compromise the structural integrity of the station, particularly under load. Techniques such as mortise-and-tenon, dovetail, or pocket-hole joinery provide varying degrees of strength and stability, depending on the application. Failure to properly execute these techniques can lead to joint failure and potential collapse.

- Leveling and Alignment

Ensuring that the structure is level and properly aligned is critical for both stability and aesthetic appeal. Uneven surfaces or misaligned components can create instability, causing the station to wobble or appear visually skewed. Employing a level and square throughout the construction process helps to maintain accurate alignment and ensure a professional finish. Failure to address leveling and alignment issues results in an amateurish appearance and potential functional problems.

- Proper Fastening Methods

The appropriate selection and application of fasteners, such as screws, nails, or bolts, are essential for securely joining lumber components. Using the wrong type or size of fastener, or failing to properly space and tighten them, can weaken the structure. Wood glue is also a crucial component, as it adds significant strength to joints when used in conjunction with mechanical fasteners. Inadequate fastening can lead to loose connections and eventual structural failure.

These elements of accurate construction are inextricably linked in the creation of a customized lumber-based beverage station. Proper adherence to precise measurements, secure joinery, accurate leveling, and appropriate fastening methods directly impact the structure’s durability, functionality, and aesthetic appeal, transforming raw materials into a robust and aesthetically pleasing social gathering point within a residence.

4. Protective Finishing

Protective finishing represents a crucial stage in the creation of any lumber-based home beverage station. It directly impacts the longevity, durability, and aesthetic appeal of the structure by safeguarding the wood from environmental factors and daily use.

- Moisture Resistance and Prevention of Decay

Protective finishes, such as sealants, varnishes, and polyurethane coatings, create a barrier against moisture penetration. This is particularly important for surfaces exposed to spills, humidity, or condensation. Unprotected wood can absorb moisture, leading to warping, swelling, and eventual decay. A properly applied finish minimizes moisture absorption, thereby extending the lifespan of the structure. For example, a bar top without a waterproof finish will quickly show signs of water damage and staining from spilled drinks.

- Scratch and Abrasion Resistance

Protective finishes provide a hard, durable surface that resists scratches and abrasions caused by regular use. This is especially critical for countertops and other surfaces that come into frequent contact with objects. Without adequate protection, the wood surface is vulnerable to scratches, dents, and other forms of physical damage. A durable finish ensures that the station maintains its appearance over time. Consider the difference between a softwood bar top finished with multiple coats of polyurethane versus an unfinished surface exposed to the wear and tear of glasses and bottles.

- UV Protection and Color Stability

Some protective finishes contain UV inhibitors that shield the wood from the damaging effects of sunlight. Prolonged exposure to UV radiation can cause fading, discoloration, and degradation of the wood. A UV-resistant finish helps to preserve the original color and appearance of the structure, especially for stations located near windows or in direct sunlight. Without UV protection, darker woods may fade, and lighter woods may yellow over time.

- Enhanced Aesthetic Appeal and Design Integration

Protective finishes not only provide practical benefits but also enhance the aesthetic appeal of the lumber-based station. Different finishes offer various levels of gloss, from matte to high-gloss, allowing for customization to match the desired style. Stains can be applied before the finish to alter the color of the wood, further integrating the station into the existing decor. A well-chosen and properly applied finish can elevate the overall look and feel of the structure.

The facets outlined above emphasize the necessity of protective finishing for any lumber-based station. Inadequate or absent finishing can lead to premature degradation, diminished aesthetic appeal, and reduced functionality. The choice of finish should align with the specific needs of the project, considering factors such as moisture exposure, wear and tear, and aesthetic preferences, leading to a visually appealing and long-lasting addition to any home.

5. Space Optimization

Space optimization, in the context of constructing a home beverage station, refers to the strategic allocation and efficient utilization of available area to maximize functionality and minimize spatial intrusion. This is particularly relevant for projects involving lumber, where dimensions are fixed and alterations can be challenging. The effective integration of a lumber-based station necessitates careful consideration of layout, storage solutions, and overall design to ensure it complements the existing environment without sacrificing usability.

- Corner Configuration Design

Corner configuration design strategically positions the bar within a corner space, maximizing utilization of otherwise underutilized areas. This design is particularly beneficial in smaller rooms where a full-sized, linear bar would impede traffic flow. An example is a custom-built, L-shaped station fitted into a dining room corner, providing a designated beverage preparation area without occupying significant floor space. The implication is a functionally complete beverage area that minimizes its impact on the overall room layout.

- Vertical Storage Integration

Vertical storage integration maximizes storage capacity by utilizing vertical space rather than solely relying on horizontal surfaces. This involves incorporating shelves, cabinets, or custom racks that extend upwards, offering ample storage for bottles, glassware, and accessories. An example is a floor-to-ceiling shelving unit integrated into the back of a lumber-based bar, providing storage without expanding the station’s footprint. The implication is increased storage capacity within a confined area, improving organization and accessibility.

- Multi-Functional Surface Adaptation

Multi-functional surface adaptation involves designing surfaces that serve multiple purposes, thereby reducing the need for additional furniture or fixtures. This can include incorporating a drop-leaf countertop that extends for additional serving space or a built-in cutting board that can be covered when not in use. An example is a lumber-based station with a hinged countertop extension that can be folded down when not needed, conserving space in a narrow room. The implication is enhanced versatility and adaptability without requiring extra area.

- Concealed Storage Implementation

Concealed storage implementation minimizes visual clutter by integrating storage compartments that are hidden from view. This can involve incorporating drawers, cabinets, or hidden compartments behind panels, creating a clean and organized appearance. An example is a lumber-based station with a faux drawer front that conceals a pull-out shelf for storing bottles or glassware. The implication is a visually streamlined and uncluttered design that integrates storage seamlessly into the overall aesthetic.

These facets illustrate how strategic planning and innovative design can optimize space utilization when constructing a lumber-based home beverage station. Successfully integrating these principles can transform a limited area into a functional and visually appealing social hub, enhancing the home’s overall utility and aesthetic.

Frequently Asked Questions

The following addresses commonly encountered inquiries regarding the design, construction, and maintenance of home beverage stations built primarily from lumber. The information provided aims to offer clarity and guidance for those undertaking such projects.

Question 1: What lumber types are best suited for countertop construction?

Hardwoods such as oak, maple, and walnut offer superior durability and resistance to wear compared to softwoods like pine or fir. Kiln-dried lumber is recommended to minimize warping and cracking post-construction.

Question 2: What are the essential tools required for constructing such a bar?

A miter saw, circular saw, drill/driver, measuring tape, level, square, sander, and clamps are considered essential. Specific projects may necessitate additional specialized tools.

Question 3: How can moisture damage be prevented in a lumber-based bar?

Application of a high-quality sealant, varnish, or polyurethane coating is critical. Regular maintenance and prompt cleanup of spills are also necessary to prevent water damage.

Question 4: What joinery techniques provide the strongest and most durable connections?

Mortise-and-tenon, dovetail, and pocket-hole joinery offer robust connections. Wood glue, in conjunction with mechanical fasteners, enhances joint strength.

Question 5: How can a lumber-based bar be customized to fit a specific space?

Careful measurement and planning are essential. Corner configurations, vertical storage solutions, and multi-functional surfaces are effective space-saving strategies.

Question 6: Are building permits typically required for constructing a home bar?

Local building codes vary. Verification of permit requirements is essential, particularly if the project involves plumbing or electrical modifications.

Understanding these key aspects will aid in the successful completion of such project. Knowledge of material selection, construction requirements, and the importance of preventive maintenance are essential to building long lasting.

The following section provides a concise summary of the core concepts discussed within this article.

DIY Wood Bar

This exploration of the lumber-based home beverage station, often termed a “diy wood bar,” has underscored the significance of material selection, meticulous design planning, accurate construction techniques, protective finishing applications, and strategic space optimization. These elements collectively determine the structural integrity, aesthetic appeal, and functional utility of such a project. Emphasis has been placed on the long-term implications of each decision, highlighting the interplay between initial choices and the ultimate lifespan and usability of the finished construction.

The creation of a customized beverage station represents a substantial undertaking, demanding a synthesis of practical skills and informed decision-making. The principles outlined herein provide a foundational framework for navigating the complexities of design and construction. With diligent planning and execution, a durable and aesthetically cohesive structure can be realized, enhancing both the functionality and value of the home environment. Future success in this endeavor hinges on the continued application of these core tenets.