A shop-built platform designed to support and elevate a power tool used for making accurate crosscuts and miter cuts is a common woodworking project. These constructions often feature adjustable height, extension wings for supporting longer workpieces, and integrated dust collection solutions. A simple example is a basic frame constructed from dimensional lumber with a flat surface for mounting the tool.

Constructing a custom support structure offers several advantages. It allows for tailoring the workstation to specific needs and available space, improving accuracy and efficiency. Such projects provide cost savings compared to commercially available alternatives. Historically, craftsmen often created custom jigs and fixtures to optimize their workflow; this practice continues today with similar projects.

The subsequent article will detail various approaches to building such a structure, considering factors like portability, material selection, and incorporating advanced features.

Construction Considerations

The following are important considerations for undertaking the construction of a custom workstation for a power tool designed for precise angle cuts.

Tip 1: Material Selection: Opt for high-quality materials such as hardwood plywood or solid lumber to ensure durability and stability of the structure. Avoid warping or twisting by acclimating the wood to the shop environment before assembly.

Tip 2: Accurate Measurements: Precise measurements are critical for the functionality of the structure. Utilize a quality measuring tape and double-check all dimensions before cutting any material. Inaccurate measurements can lead to instability or misalignment.

Tip 3: Secure Fastenings: Employ robust fastening techniques, such as screws and glue, to ensure a rigid and long-lasting assembly. Consider using pocket hole joinery for added strength and ease of assembly, particularly when using plywood.

Tip 4: Integrated Dust Collection: Incorporate a dust collection system into the design. This can be achieved by creating a custom hood or enclosure around the cutting area and connecting it to a shop vacuum. Effective dust collection improves visibility and minimizes cleanup.

Tip 5: Adjustable Height: Design the structure with an adjustable height mechanism. This allows the user to match the height of the structure to other work surfaces in the shop, facilitating efficient workflow and minimizing strain.

Tip 6: Extension Wings: Implement extension wings to provide support for longer workpieces. These wings can be fixed or adjustable, and should be sturdy enough to handle the weight of the material without sagging.

Tip 7: Portability Considerations: If portability is a concern, incorporate wheels or casters into the design. Ensure the wheels are lockable to prevent movement during use.

Careful consideration of these aspects leads to a functional and reliable addition to the workshop. The result is a tool enhancing accuracy and safety, while promoting efficiency.

The ensuing section will focus on specific designs and project plans.

1. Stability

Stability represents a fundamental requirement for a functional shop-built platform designed for supporting a power tool used for making accurate crosscuts and miter cuts. Its absence undermines the precision of the tool’s cuts, potentially leading to flawed projects and unsafe operating conditions. Therefore, achieving a stable structure is paramount.

- Frame Rigidity

Frame rigidity directly influences the support structure’s ability to resist deformation under load. A frame constructed from insufficient materials or with inadequate joinery will flex during use, resulting in inaccurate cuts. For example, a frame built with thin plywood and lacking proper bracing will likely exhibit noticeable deflection. Implementing robust joinery techniques and selecting high-quality materials are vital to ensuring frame rigidity.

- Level Surface

A perfectly level surface is essential for consistent results. Any deviation from level introduces error into the cutting process. Imagine a work surface with a slight warp; the workpiece will not sit flush, causing the cut angle to deviate from the intended setting. Ensuring the top surface is level, and remains so, is a crucial aspect of stability.

- Vibration Dampening

Power tools generate vibrations during operation. Excessive vibration can compromise cut quality and user control. A well-designed structure minimizes vibration transmission through strategic material selection and construction techniques. For instance, using rubber feet or incorporating damping materials can significantly reduce vibration effects.

- Secure Tool Mounting

The method of securing the tool to the support structure directly affects stability. A loosely mounted tool will shift during operation, negating any efforts to achieve a stable platform. Utilizing bolts and washers, combined with a properly sized mounting surface, ensures the tool remains firmly in place.

These four facets frame rigidity, level surface, vibration dampening, and secure tool mounting each contribute to the overall stability of a shop-built workstation. Without a stable foundation, the potential for precise, repeatable cuts is severely diminished. Prioritizing stability is therefore critical for maximizing the utility and safety of such a tool.

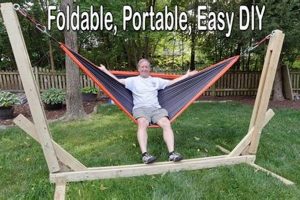

2. Portability

Portability introduces adaptability to a shop-built platform designed for supporting a power tool used for making accurate crosscuts and miter cuts. Its inclusion transforms a stationary tool into one capable of deployment across diverse worksites. The integration of mobility features enhances project versatility and workspace efficiency.

- Wheel Integration

Wheel integration directly affects ease of movement. The selection of appropriate wheel types and mounting hardware impacts the ability to traverse various surfaces. Small, fixed wheels may suffice for smooth floors, while larger, swiveling, locking casters offer greater maneuverability on uneven terrain. Load capacity and durability are also key factors. Failure to adequately address these factors results in a cumbersome and unwieldy assembly.

- Collapsible Design

A collapsible design minimizes storage footprint and facilitates transport in confined spaces. Hinged components and quick-release mechanisms enable rapid assembly and disassembly. Consider, for instance, a folding leg system that reduces the structure’s profile for convenient storage against a wall or within a vehicle. Structural integrity must be maintained during both deployed and collapsed states.

- Weight Optimization

Weight optimization influences the effort required to move the structure. Material selection plays a pivotal role; lighter materials such as aluminum or thinner gauge steel reduce the overall mass. However, weight reduction cannot compromise structural integrity. Reinforcement strategies, such as bracing and gussets, may be necessary to maintain stability while minimizing weight.

- Handle Placement

Strategic handle placement enhances user ergonomics during transport. Handles should be positioned to distribute weight evenly and facilitate a comfortable grip. Recessed handles or integrated grips prevent obstruction and potential damage during storage and transport. Poorly positioned handles can lead to awkward lifting angles and increased strain.

These four considerationswheel integration, collapsible design, weight optimization, and handle placementdefine the portability of a shop-built support structure. Addressing each factor ensures the resulting system offers both mobility and functional utility. Balancing these aspects yields a mobile workstation suitable for a wide array of jobsite conditions.

3. Material Durability

Material durability constitutes a critical attribute for shop-built platforms designed to support power tools. The longevity and sustained functionality of these constructions hinge directly upon the materials used in their fabrication. Selection must account for the rigors of workshop environments and the repetitive stresses imposed during operation.

- Wood Species Selection

The choice of wood species dictates the structure’s resistance to wear and tear. Hardwoods, such as maple or oak, provide superior strength and dent resistance compared to softwoods like pine or fir. For instance, a frame constructed from oak will withstand impacts and heavy loads more effectively than one made from pine, thereby extending its service life. The appropriate species selection is crucial for withstanding demanding environments.

- Protective Coatings

The application of protective coatings mitigates the damaging effects of moisture, chemicals, and abrasion. Finishes such as polyurethane or epoxy create a barrier that shields the wood from environmental factors. A sealed surface prevents water absorption, reducing the risk of warping or rot, and protects against accidental spills of solvents or adhesives. Neglecting protective coatings compromises the long-term integrity of the construction.

- Hardware Quality

The quality of fasteners and hardware contributes significantly to overall durability. Inexpensive screws and bolts are prone to corrosion and failure under stress. Employing high-grade steel hardware, such as stainless steel or zinc-plated components, ensures secure and lasting connections. The failure of a single fastener can compromise the structural integrity, highlighting the importance of hardware quality.

- Joint Strength

The method of joining materials influences the overall strength and stability. Robust joinery techniques, such as mortise-and-tenon or dovetail joints, provide superior resistance to stress compared to simpler methods like butt joints secured with nails. Strong joints prevent racking and loosening over time, ensuring the structure remains rigid and stable throughout its service life. Effective joint construction is a key determinant of long-term performance.

These four elements wood species selection, protective coatings, hardware quality, and joint strength collectively determine the material durability of a shop-built workstation. Careful attention to these details yields a structure capable of withstanding the demands of a workshop environment, providing reliable support and extended service life. The cumulative effect of these considerations is a significant factor in the long-term value of the resulting build.

4. Dust Management

Effective dust management is intrinsically linked to the functional design and utility of a shop-built platform designed for supporting a power tool used for making accurate crosscuts and miter cuts. The mitigation of airborne particulate matter during operation directly impacts user health, tool longevity, and the overall cleanliness of the workspace. Integration of appropriate dust collection solutions is therefore a critical consideration during the design and construction phases.

- Enclosure Design

The enclosure design significantly influences the capture and containment of dust generated during cutting operations. A partial or full enclosure surrounding the cutting area can effectively prevent the dispersal of dust into the surrounding environment. For example, constructing a hood behind the tool and connecting it to a dust collection system creates a localized vacuum, drawing airborne particles away from the user and into a collection receptacle. Effective enclosure design minimizes exposure to harmful respirable dust.

- Vacuum System Integration

The integration of a vacuum system represents a primary means of dust removal. Connecting a shop vacuum or dedicated dust collector to the tool’s dust port, or an enclosure surrounding the tool, allows for the direct extraction of dust at its source. The effectiveness of the system depends on the vacuum’s airflow capacity and the diameter of the connection hose. For example, a high-volume, low-pressure system is more effective at capturing fine dust particles than a standard shop vacuum with a small hose. The choice of vacuum system directly impacts the amount of airborne dust.

- Air Filtration

Air filtration systems complement direct dust collection by capturing residual airborne particles that escape the primary collection system. Installing an air filtration unit in the workshop removes fine dust that can remain suspended in the air for extended periods. These units typically employ multiple filters, including a pre-filter to capture larger particles and a HEPA filter to remove microscopic dust. An example would be ceiling-mounted air filtration units that cycle air through filters, improving air quality. Efficient air filtration contributes to a healthier work environment.

- Material Selection for Dust Control

The materials used in the construction of a shop-built platform can influence dust accumulation and ease of cleaning. Smooth, non-porous surfaces, such as sealed plywood or melamine, prevent dust from adhering and simplify cleanup. Conversely, rough or porous surfaces, like unfinished wood, tend to trap dust and are difficult to clean. Selecting materials that minimize dust accumulation reduces the frequency of cleaning and improves the overall hygiene of the workspace.

These facets enclosure design, vacuum system integration, air filtration, and material selection for dust control underscore the importance of integrating comprehensive dust management strategies into the construction and utilization of shop-built platforms. Addressing these factors minimizes health risks, enhances visibility, and contributes to a cleaner and more efficient workshop environment. The conscientious application of these principles is critical for ensuring user well-being and operational safety.

5. Workpiece Support

Workpiece support constitutes a foundational element in the design and construction of a shop-built platform designed for supporting a power tool used for making accurate crosscuts and miter cuts. The presence of adequate support directly influences the precision, safety, and efficiency of cutting operations. Inadequate support leads to material instability, compromised cut accuracy, and elevated risk of workpiece kickback. The integration of effective support mechanisms is therefore indispensable to the overall functionality.

Extension wings, for example, represent a common approach to workpiece support. These extend the effective working surface of the platform, accommodating longer materials that would otherwise cantilever unsupported. The absence of these wings necessitates reliance on makeshift supports, such as sawhorses or ad hoc arrangements, increasing the likelihood of material movement during cutting. Similarly, adjustable rollers or flip-down supports provide variable height accommodation, ensuring the workpiece remains level with the tool’s table, minimizing the risk of binding and improving cut consistency. Consider a scenario where a long piece of trim is being cut; without proper extension wings, the unsupported end can sag, causing an inaccurate cut or even causing the material to bind in the saw. These types of support ensures repeatable results and a smooth workflow.

In summary, workpiece support is not merely an accessory but an integral component of a functional and safe platform. Its impact ranges from enhancing cut accuracy to minimizing potential hazards. While the specific implementation of support mechanisms varies depending on project requirements and available resources, the underlying principle remains constant: to provide stable and reliable support to the workpiece throughout the cutting process. The challenges associated with material support, particularly with long or heavy workpieces, underscore the practical significance of incorporating robust support strategies into platform designs. These strategies directly contribute to achieving professional-quality results and a safer working environment.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the construction and utilization of a custom-built structure designed to support a power tool used for making accurate crosscuts and miter cuts.

Question 1: What are the primary benefits of constructing a custom support structure versus purchasing a commercially available stand?

Custom construction allows for tailoring the dimensions, features, and materials to specific needs and shop constraints. It can also provide a cost-effective alternative to commercially available options. Factory-made stands may not accommodate unique spatial requirements or desired functionalities.

Question 2: What type of materials are best suited for a robust and durable structure?

Hardwoods, such as maple or oak, and high-quality plywood are preferred due to their strength and resistance to warping. Dimensional lumber, properly selected and treated, can also provide a suitable foundation. The choice of material should align with the project’s intended use and budget considerations.

Question 3: How does one ensure adequate stability in a shop-built support structure?

Stability is achieved through robust frame construction, precise joinery, and a level work surface. Bracing, secure fasteners, and vibration-dampening measures contribute to a solid and stable platform. Regular inspection and maintenance are essential for preserving stability over time.

Question 4: Is it possible to incorporate dust collection into a shop-built structure?

Yes, it is possible. An enclosure or hood can be integrated around the cutting area and connected to a shop vacuum or dust collector. Effective dust collection enhances visibility, minimizes cleanup, and mitigates health risks associated with airborne particulate matter.

Question 5: How does one address portability considerations in a shop-built structure?

Portability is achieved by integrating wheels or casters, implementing a collapsible design, and optimizing weight through material selection. Consideration should be given to the type of terrain and storage constraints. Ensuring wheels are lockable is important for safe, stationary use.

Question 6: What are the critical safety considerations when designing and using a shop-built miter saw stand?

Ensuring stability, implementing effective dust collection, providing adequate workpiece support, and adhering to the manufacturer’s safety guidelines for the power tool are of utmost importance. Regular inspection of the structure for damage or wear is also crucial. Protective eyewear and hearing protection should always be used during operation.

In conclusion, the construction of a shop-built support platform for a miter saw involves careful planning, material selection, and adherence to safety protocols. Addressing common concerns through informed design and construction practices results in a valuable addition to any workshop.

The subsequent section will provide a summary of key takeaways and offer recommendations for further learning.

Conclusion

This exploration of constructing a shop-built platform for a power tool used for making accurate crosscuts and miter cuts emphasized stability, portability, material durability, dust management, and workpiece support. Each element contributes to the construction of a safe, functional, and long-lasting tool support system. Successful implementation involves careful planning, precise execution, and an understanding of material properties and woodworking techniques.

The pursuit of a customized workspace, while demanding, yields a tool uniquely tailored to specific needs and operational environments. Further research and practical application of these principles are encouraged to refine skills and optimize workshop practices. The enduring value of a well-executed platform lies in its ability to enhance precision, efficiency, and safety in woodworking endeavors.