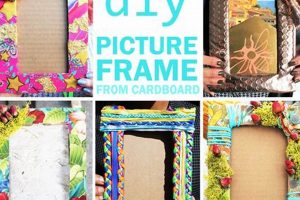

The construction of large-scale enclosures designed to showcase images, artwork, or other visual media through individual creation is explored. Such projects entail the customized fabrication of framing elements, often exceeding standard dimensional constraints, undertaken by individuals rather than commercial entities. For instance, an individual might build a sizable border for a canvas print using reclaimed wood and basic carpentry tools.

The significance of these projects lies in their capacity to personalize interior spaces and provide a unique presentation format for visual content. They offer cost-effective alternatives to purchasing pre-made, oversized frames, while also promoting resourcefulness and creative expression. Historically, the practice of crafting custom frames has been driven by both economic necessity and the desire to exert artistic control over the display of cherished possessions.

The subsequent sections will examine material selection, construction techniques, and finishing options applicable to these large-format projects. Consideration will be given to factors such as structural integrity, aesthetic considerations, and the efficient use of available resources to achieve desired outcomes.

Construction Guidelines for Oversized Display Enclosures

The following guidelines address crucial considerations for building structurally sound and aesthetically pleasing oversized display enclosures.

Tip 1: Material Selection is Paramount. Utilize high-quality lumber, ensuring adequate thickness and strength to support the frame’s dimensions. Avoid warped or knotty wood, as these imperfections compromise structural integrity.

Tip 2: Precise Measurements are Essential. Accurate calculations of internal and external dimensions are critical. Prior to cutting any materials, double-check all measurements against the artwork or image to be displayed. Consider a tolerance allowance to prevent a tight fit.

Tip 3: Employ Robust Joinery Techniques. Mitered corners reinforced with splines, dowels, or metal fasteners provide superior strength compared to simple butt joints. Proper clamping during glue-up is crucial for a durable bond.

Tip 4: Incorporate Adequate Backing Support. A rigid backing material, such as foam board or hardboard, is necessary to prevent sagging and maintain the artwork’s flatness. Secure the backing to the frame using screws or specialized framing hardware.

Tip 5: Consider Weight Distribution. For exceptionally large frames, implement a multi-point hanging system to distribute the weight evenly across the wall. Employ heavy-duty picture hanging hardware rated to handle the frame’s weight.

Tip 6: Apply a Protective Finish. A durable finish, such as varnish or lacquer, protects the wood from moisture and scratches. Choose a finish that complements the artwork and the surrounding decor. Ensure proper ventilation during the application process.

Tip 7: Account for Expansion and Contraction. Wood expands and contracts with changes in humidity. Leave a slight gap between the artwork and the frame’s rabbet to accommodate this movement and prevent warping or damage.

Adhering to these guidelines will result in a robust and visually appealing oversized display enclosure that effectively showcases the chosen artwork or image.

The following section will discuss various aesthetic finishing techniques for these large-format projects.

1. Material Durability

Material durability is a critical factor in the successful construction of oversized visual display structures. Given the scale and weight considerations inherent in these projects, the longevity and stability of the chosen materials directly impact the overall lifespan and performance of the enclosure.

- Wood Species Selection

The selection of wood species profoundly influences the frame’s resistance to warping, cracking, and decay. Hardwoods, such as oak or maple, offer superior strength and dimensional stability compared to softwoods like pine. For example, a frame constructed from kiln-dried hardwood is less susceptible to moisture-related deformation, ensuring the artwork remains securely displayed over time.

- Moisture Content Management

The moisture content of the chosen wood is a critical determinant of its long-term stability. Lumber with excessive moisture content is prone to shrinkage and warping as it dries, potentially compromising the structural integrity of the frame. Therefore, utilizing kiln-dried lumber with a consistent moisture content is imperative. A deviation from recommended moisture levels can cause a visually impressive, oversized frame to degrade and fail prematurely.

- Resistance to Insect Infestation

Depending on the environmental conditions and the type of wood utilized, the frame may be susceptible to insect infestation. Certain wood species possess natural resistance to insects, while others require protective treatments. Ignoring this aspect may results in structural weakness. Consider a frame that’s made from pine which is vulnerable to wood-boring insects. If left untreated, the frame would eventually collapse, damaging the artwork and requiring replacement.

- Fastener Selection and Compatibility

The choice of fasteners, such as screws or nails, must be compatible with the selected wood species to prevent corrosion or degradation. Using inappropriate fasteners can lead to weakened joints and structural failure. Employing stainless steel screws in conjunction with hardwood, for instance, minimizes the risk of rust and ensures a secure and lasting connection.

The integration of durable materials with careful attention to environmental factors and compatible hardware contributes significantly to the creation of oversized display enclosures that withstand the test of time. A failure to prioritize material durability can lead to costly repairs, artwork damage, or complete structural failure. Therefore, the initial investment in quality materials directly translates to long-term value and performance.

2. Dimensional Accuracy

Dimensional accuracy is a cornerstone of successful construction. This precision directly impacts the final appearance, structural integrity, and the overall ability of the structure to function as intended. When deviating from strict adherence to specified measurements, particularly when scaling up dimensions for larger-format builds, cumulative errors can occur, which compromises intended outcomes. For example, a failure to account for precise angles in mitered corners or variations in material thickness will cause visible misalignment and structural instability. An improperly sized internal space will render the enclosure useless.

Achieving dimensional accuracy necessitates meticulous planning and execution, and also requires a thorough understanding of material properties. The selection of tools suited for precision cutting and assembly is essential. Furthermore, an understanding of how environmental factors such as temperature and humidity can influence material dimensions is crucial, as these fluctuations can introduce inaccuracies during the build process. A real-world scenario might involve a project where the internal dimensions are miscalculated, resulting in the artwork not fitting properly within the completed enclosure. In such cases, rework or even complete reconstruction of the frame may be necessary, leading to wasted time, materials, and financial losses.

In summary, the relationship between dimensional accuracy and achieving a successful DIY giant picture frame is a direct one: precision in measurement and execution are indispensable. The potential consequences of neglecting this aspect range from aesthetic flaws to structural failure. Accurate planning, correct material handling, and the utilization of proper tools are imperative for creating an oversized display enclosure that fulfills both its functional and aesthetic objectives.

3. Joint Reinforcement

Joint reinforcement is paramount in the construction of large-scale enclosures designed to display visual media. The extended dimensions and resulting weight place substantial stress on the joints connecting frame components. Without adequate reinforcement, these joints are prone to failure, compromising the structural integrity and longevity of the entire piece.

- Mechanical Fasteners

Mechanical fasteners, such as screws, bolts, and nails, provide a direct physical connection between frame elements. The type, size, and spacing of fasteners must be carefully considered to ensure sufficient holding power. For instance, using excessively short screws in a mitered corner joint will result in a weak connection that may fail under load. Conversely, properly sized and spaced screws provide a robust and reliable bond, distributing stress and preventing joint separation. Choosing fasteners resistant to corrosion is critical for outdoor or high-humidity environments.

- Adhesive Bonding

Adhesives, particularly wood glues, contribute significantly to joint strength by creating a continuous bond between surfaces. The selection of appropriate glue is crucial; polyvinyl acetate (PVA) glues are suitable for general woodworking applications, while polyurethane glues offer enhanced water resistance and gap-filling properties. Proper clamping pressure during the glue curing process ensures optimal adhesion. Neglecting to apply sufficient clamping force will weaken the bond, increasing the risk of joint failure. A properly executed glue joint, in conjunction with mechanical fasteners, creates a robust and durable connection.

- Joinery Techniques

Employing robust joinery techniques, such as mortise and tenon, dovetail, or biscuit joints, enhances the mechanical interlock between frame components. These techniques provide a larger surface area for gluing and a mechanical resistance to racking forces. For example, a mortise and tenon joint, where a projecting tenon fits snugly into a corresponding mortise, creates a strong and stable connection that resists both tension and shear stresses. While more complex to execute, these joinery methods offer superior joint strength compared to simple butt joints.

- Corner Reinforcement

Corners are particularly vulnerable to stress in large-scale enclosures. Reinforcing corners with metal or wooden brackets, splines, or corner blocks distributes stress and prevents racking or twisting. A metal corner bracket, for instance, provides a rigid connection that resists deformation under load. Conversely, a simple glued butt joint at a corner offers minimal resistance to stress and is highly susceptible to failure. Strategic corner reinforcement is essential for maintaining the structural integrity and dimensional stability of the completed piece.

In summary, effective joint reinforcement is not merely an optional add-on but a fundamental requirement for the construction of substantial, custom enclosures for displaying images. The combination of mechanical fasteners, adhesive bonding, advanced joinery techniques, and strategic corner reinforcement provides the necessary strength and stability to withstand the stresses inherent in large-format projects, ensuring the longevity and aesthetic appeal of the finished product.

4. Backing Stability

Backing stability is a critical determinant of the overall success and longevity of self-constructed, oversized image display structures. Its significance stems from the direct support it provides to the artwork or visual medium, preventing sagging, warping, and potential damage. The absence of a stable backing material leads to a visual distortion of the displayed content and potential degradation of the art itself. For instance, a large photograph placed within a homemade frame without adequate rear support will eventually bow in the center due to gravitational forces, compromising its aesthetic appeal and potentially causing permanent creases or folds. Therefore, selecting and implementing appropriate backing materials is essential to maintaining the visual integrity of the displayed item.

The materials used for backing large-format frames range from rigid foam core and corrugated plastic sheeting to hardboard and plywood. The choice of material should be informed by several factors, including the size and weight of the artwork, the desired level of rigidity, and the environmental conditions to which the frame will be exposed. For example, in damp environments, moisture-resistant hardboard or plastic sheeting are preferable to prevent warping or mold growth. Proper attachment of the backing material to the frame is equally important; screws, staples, or specialized framing hardware should be used to create a secure and even distribution of support. Insufficient or improperly placed fasteners can result in localized stress points, leading to buckling or separation of the backing material from the frame. To illustrate, consider the case of a custom-built frame using lightweight plywood as a backing material attached with staples spaced too far apart. Over time, the plywood may separate from the frame, resulting in unsightly gaps and a loss of support for the displayed artwork.

In conclusion, backing stability is not merely a secondary consideration but an integral component of any do-it-yourself large format enclosure project. Choosing the right materials, employing proper attachment techniques, and accounting for environmental factors ensures long-term preservation of the displayed content. Overlooking backing stability can result in costly repairs, irreversible damage to artwork, and a compromised aesthetic presentation. The selection and implementation of appropriate backing solutions should therefore be a priority.

5. Weight Distribution

The construction of large-scale display frames necessitates a thorough consideration of weight distribution. As the physical dimensions of the enclosure increase, so does the weight of the frame itself and any enclosed visual media. Improper weight distribution introduces a significant risk of structural failure, posing a safety hazard and potentially causing damage to the displayed content. A poorly balanced frame exerts uneven stress on its support system, whether it be wall anchors, hanging wires, or a freestanding structure. This uneven stress concentration can lead to warping, cracking, or complete detachment of the frame from its mounting. As a practical example, consider a large frame fabricated from solid wood, hung using a single wire across the center. The weight of the frame will likely cause the wire to strain and potentially snap, or the frame to pull away from the wall, resulting in damage to both the frame and the artwork. Therefore, appropriate measures must be taken to ensure balanced weight distribution.

Effective weight distribution strategies involve several key considerations. The first is the selection of appropriately rated hanging hardware. For heavier frames, multiple attachment points are essential to distribute the load across a wider area. High-quality D-rings, heavy-gauge wire, and robust wall anchors are necessary. The placement of these attachment points is also critical. They should be positioned strategically to counteract any inherent imbalances in the frame’s design. For instance, if a frame has a particularly heavy section, additional support points should be added near that area. Furthermore, the use of a backing board constructed from a lightweight yet rigid material, such as foam core or aluminum composite, can minimize the overall weight of the frame without sacrificing structural integrity. These materials offer superior support compared to traditional hardboard, reducing the burden on the hanging system and mitigating the risk of failure.

In summary, weight distribution is not a mere afterthought but an integral aspect of design and construction. Addressing potential imbalances through strategic hardware placement, selecting appropriate materials, and implementing robust support systems are paramount for ensuring the safety, stability, and longevity of the finished product. Ignoring these considerations can result in structural compromise, damage to valuable artwork, and potential injury. Therefore, a comprehensive understanding and meticulous application of weight distribution principles is critical for any individual undertaking the construction of a large-scale image display frame.

6. Aesthetic Finishing

Aesthetic finishing represents a critical juncture in the construction of a do-it-yourself, oversized visual display frame. It is the final stage where utilitarian construction transforms into a visually cohesive element, capable of enhancing the artwork it contains and harmonizing with its surrounding environment. The choice of finishing techniques directly impacts the perceived value and overall appeal of the piece. A poorly executed finish detracts from the visual impact of the displayed content, whereas a well-applied finish elevates both the artwork and the frame itself. The selection of stains, paints, or textured coatings should align with the style of the art and the decor of the room. For instance, a rustic frame crafted from reclaimed wood may benefit from a distressed finish to accentuate its natural character, while a modern piece may demand a sleek, high-gloss coating for a contemporary appearance. The absence of careful aesthetic consideration ultimately undermines the time and effort invested in the preceding construction phases.

The practical application of aesthetic finishing encompasses various techniques, each requiring specific tools and skillsets. Staining involves the application of colored dyes to penetrate the wood grain, enhancing its natural beauty and depth. Painting provides a broader spectrum of color options and allows for complete coverage of the wood surface. Textured finishes, such as faux stone or metallic effects, introduce visual interest and tactile qualities. Prior to applying any finish, meticulous surface preparation is essential. Sanding smooths imperfections, fills cracks, and creates a uniform base for optimal adhesion. The application process itself necessitates careful technique to avoid runs, drips, or uneven coverage. Multiple coats are often required to achieve the desired depth of color and durability. A protective topcoat, such as varnish or lacquer, seals the finish and provides resistance to scratches, moisture, and UV damage. Consider a scenario where a frame is constructed from high-quality lumber but receives a rushed and uneven paint job; the resulting imperfections detract from the overall aesthetic, diminishing the frame’s value and its ability to complement the artwork.

In summary, aesthetic finishing is not merely an ornamental addition but an integral component of a successful do-it-yourself large format project. It serves as the final touch that transforms a structurally sound frame into a visually appealing and cohesive display element. Challenges associated with aesthetic finishing include selecting appropriate materials, mastering application techniques, and achieving a durable and long-lasting result. The pursuit of excellence in aesthetic finishing ultimately contributes to the creation of a frame that enhances the value and visual impact of the artwork it contains, while seamlessly integrating into its surrounding environment. It requires patience and skill. If the aesthetic finishing is overlooked, the time and effort spent into diy giant picture frame will be in vain.

Frequently Asked Questions

The subsequent section addresses common inquiries and misconceptions regarding the fabrication and implementation of large-scale visual display enclosures.

Question 1: What is the optimal method for joining corners in a large-format frame to ensure structural integrity?

Mitered corners reinforced with splines, dowels, or metal fasteners provide superior strength compared to butt joints. Proper clamping during glue application is crucial.

Question 2: What type of backing material is most suitable for preventing sagging in an oversized frame?

Rigid materials such as foam board, hardboard, or thin plywood, secured with screws or specialized framing hardware, are recommended to maintain flatness and prevent distortion.

Question 3: How does one effectively distribute the weight of an exceptionally large frame to ensure secure wall mounting?

Implement a multi-point hanging system utilizing heavy-duty picture hanging hardware rated to handle the frame’s weight. Distribute mounting points to balance the load.

Question 4: What type of finish is best suited for protecting a wooden frame from moisture and scratches?

Durable finishes such as varnish or lacquer provide a protective barrier against environmental factors. Select a finish that complements the artwork and the surrounding decor.

Question 5: Is it necessary to account for wood expansion and contraction when constructing a large frame?

Yes. Leave a slight gap between the artwork and the frame’s rabbet to accommodate dimensional changes due to humidity and temperature fluctuations, preventing warping or damage.

Question 6: What are the key considerations when selecting wood for constructing a long-lasting, oversized frame?

Choose high-quality lumber with adequate thickness and strength. Avoid warped or knotty wood, as these imperfections compromise structural integrity. Ensure proper kiln-drying to minimize moisture content.

Adhering to these recommendations contributes significantly to the creation of robust and visually appealing oversized display enclosures.

The following section will delve into advanced techniques for achieving professional-grade results in large-format framing projects.

DIY Giant Picture Frame

This exploration has examined the multifaceted aspects of constructing oversized visual display structures. From material selection and joint reinforcement to backing stability, weight distribution, and aesthetic finishing, each element contributes critically to the successful creation of a durable and visually compelling piece. Ignoring these foundational principles increases the risk of structural failure, aesthetic compromise, and potential damage to displayed artwork. The precision required in dimensional accuracy and the strategic application of appropriate techniques are not mere suggestions, but imperatives.

The construction of a DIY giant picture frame demands a commitment to meticulous planning, skilled execution, and a thorough understanding of material properties. The pursuit of excellence in this endeavor requires more than just basic carpentry skills; it necessitates a comprehensive approach that integrates structural integrity with aesthetic appeal. By adhering to the principles outlined herein, individuals can create impressive and enduring displays that enhance the value and impact of their visual content for years to come. Continued exploration and refinement of these techniques will further elevate the art of large-format display framing.