Creating a homemade representation of the iconic character from The Wonderful Wizard of Oz involves assembling readily available materials to simulate the metallic appearance associated with the individual. This commonly entails the modification of clothing, often through painting or the application of metallic-toned materials, to achieve a resemblance to the character’s distinctive aesthetic. For example, individuals might use silver spray paint on cardboard to fashion a chest piece or employ flexible dryer ducting to create articulated limbs.

Engaging in this type of creative endeavor offers several advantages. It presents a cost-effective alternative to commercially manufactured ensembles, allowing for personalization and resourcefulness. Furthermore, it fosters creativity and problem-solving skills. The history of homemade interpretations of fictional characters demonstrates a long-standing tradition of imaginative expression, particularly within the context of celebratory events or theatrical productions.

The following sections will provide detailed instructions and ideas for constructing various components of this unique creation. Considerations for safety, material selection, and design modifications will be addressed to facilitate a successful and enjoyable fabrication process.

Guidance for a Self-Made Metallic Woodsman Ensemble

The following recommendations provide practical advice for constructing a convincing and durable homemade representation of the character. Adherence to these guidelines will enhance the final product and ensure a safe and enjoyable crafting experience.

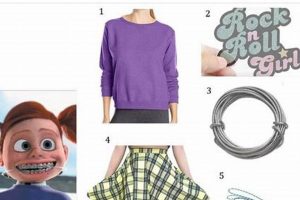

Tip 1: Material Selection. Opt for lightweight and readily available materials such as corrugated cardboard, aluminum foil, or craft foam. Heavier materials may impede mobility and comfort, particularly during extended wear. Conduct a cost-benefit analysis of each option to balance aesthetic appeal with practical considerations.

Tip 2: Surface Treatment. Employ metallic spray paint specifically designed for application on the chosen materials. Ensure adequate ventilation during the painting process and allow sufficient drying time to prevent smudging or transfer of the finish. Multiple thin coats are preferable to a single thick coat for enhanced adhesion and a more uniform appearance.

Tip 3: Articulation Design. Incorporate flexible joints in areas such as the elbows and knees to facilitate movement. Consider using hinges, elastic straps, or strategically placed gaps to permit a range of motion without compromising the overall design. Prioritize functionality alongside visual appeal.

Tip 4: Headgear Construction. Exercise caution when constructing the headpiece to ensure proper ventilation and visibility. Avoid using sharp or protruding elements that could pose a safety hazard. Secure the headpiece firmly to prevent it from shifting or obstructing vision during wear.

Tip 5: Comfort and Fit. Prioritize comfort by incorporating padding or cushioning in areas that come into direct contact with the body. Ensure that the ensemble fits properly and does not restrict breathing or circulation. Conduct a trial run to identify and address any potential discomfort issues before extended use.

Tip 6: Authenticity and Detail. While striving for a recognizable representation, consider incorporating unique details that reflect individual creativity. Experiment with different textures, embellishments, and finishing techniques to personalize the ensemble while maintaining the core characteristics of the character.

Tip 7: Safety Precautions. Supervise children during the construction process and ensure that all tools and materials are used responsibly. Avoid using flammable materials near open flames or heat sources. Store the completed ensemble in a safe location away from potential hazards.

These tips emphasize the importance of planning, material selection, and safety considerations in achieving a successful outcome. By adhering to these recommendations, individuals can create a memorable and visually appealing representation of the character while minimizing potential risks.

The subsequent section will address the practical application of these principles, offering step-by-step instructions for constructing specific components of this unique creation.

1. Material selection

Material selection is a foundational aspect of successfully creating this unique representation. The choice of materials directly influences the final aesthetic, structural integrity, and wearability of the crafted ensemble. For instance, corrugated cardboard, frequently utilized due to its affordability and ease of manipulation, requires reinforcement to prevent deformation, particularly in areas subject to stress. Conversely, sheet metal, while providing a more authentic metallic appearance and enhanced durability, necessitates specialized tools and safety precautions during fabrication. Ineffective material selection can lead to a fragile or uncomfortable representation, undermining the overall objective.

Consider the example of constructing articulated limbs. Utilizing rigid materials such as PVC pipe without incorporating flexible joints restricts movement, rendering the ensemble impractical for extended wear. Conversely, employing overly pliable materials like thin craft foam may result in limbs that lack structural support and exhibit an unrealistic, floppy appearance. A balanced approach, incorporating both rigid and flexible materials in strategic locations, is essential for achieving both aesthetic fidelity and functional mobility. The decision to utilize aluminum foil for surface embellishment presents a further example. While aluminum foil offers a readily available and reflective surface, it is susceptible to tearing and creasing. Its successful application requires careful adherence and a protective coating to enhance durability.

In summary, material selection is not merely a preliminary step but an integral component influencing the entire crafting process and the ultimate success of the homemade representation. Challenges in sourcing appropriate materials or implementing necessary modifications can impact the project timeline and overall feasibility. A thorough understanding of material properties and their suitability for specific components is critical for realizing a durable, visually appealing, and functional representation of the character. The practical significance of informed material selection extends beyond aesthetics, directly impacting wearer comfort, safety, and the longevity of the constructed ensemble.

2. Paint application

Effective paint application is paramount in creating a convincing homemade representation of the metallic woodsman. The selection and implementation of paint directly determine the visual success of simulating a metallic surface. For instance, uneven application of silver spray

paint results in a patchy, unrealistic appearance, detracting from the overall illusion. Conversely, employing multiple thin coats of metallic paint, allowing each layer to dry fully, produces a smoother, more convincing finish. Furthermore, the use of a primer before applying the metallic coat enhances adhesion and prevents the underlying material from affecting the paint’s final color and sheen.

The practical implications of proper paint application extend beyond mere aesthetics. A durable finish protects the underlying material from wear and tear, increasing the lifespan of the homemade representation. Consider the use of a clear sealant after the metallic paint has dried; this provides a protective barrier against scratches and abrasions, particularly in areas subject to friction. Furthermore, the choice of paint formulation is critical. Selecting a paint specifically designed for the chosen material ensures proper adhesion and prevents cracking or peeling over time. For example, paint intended for plastic surfaces should be used on plastic components, while paint formulated for metal should be applied to metallic elements.

In conclusion, paint application is not simply a superficial step but an integral process that significantly impacts the visual fidelity and longevity of the homemade creation. Attention to detail, proper surface preparation, and the selection of appropriate paint formulations are crucial for achieving a convincing and durable metallic appearance. The successful execution of this stage transforms basic materials into a recognizable and visually appealing representation of the character, contributing substantially to the overall success of the project.

3. Joint articulation

Joint articulation is a critical element in the successful creation of a homemade representation of the iconic character. The extent to which the constructed ensemble allows for natural movement directly impacts the wearer’s mobility and the overall realism of the representation. An inability to bend limbs or turn the torso severely limits the wearer’s ability to convincingly embody the character. For example, a costume constructed with rigid, unyielding materials might accurately replicate the appearance of metal, but would simultaneously render the wearer virtually immobile.

One effective approach to achieving articulated joints involves the strategic use of flexible materials at key points, such as the elbows, knees, and shoulders. Hinges, elastic straps, and accordion-style construction are also viable options. The selection of materials and construction techniques should be informed by a careful assessment of the desired range of motion and the structural integrity of the overall design. Consider, for instance, the use of flexible dryer ducting for creating articulated limbs; while readily available and relatively inexpensive, this material requires careful reinforcement to prevent collapse under its weight. The success of the articulated joints is also influenced by the overall weight and distribution of the materials used in the broader construction. Heavier materials necessitate stronger and more robust articulation mechanisms to ensure stability and prevent strain on the wearer.

In summary, joint articulation is not merely a design consideration, but a functional necessity for a convincing and wearable ensemble. The effective implementation of articulated joints requires a thoughtful balance between aesthetic accuracy, material selection, and structural engineering. Challenges in achieving this balance can result in a visually impressive but ultimately impractical creation. This understanding is particularly significant for those engaging in the homemade fabrication process, as it underscores the importance of prioritizing functionality alongside visual appeal.

4. Headgear safety

The construction of headgear for a homemade representation necessitates careful consideration of safety factors. The proximity of the headpiece to the wearer’s face and the potential for restricted vision or ventilation mandate a cautious approach to design and material selection.

- Material Toxicity

The selection of non-toxic materials is paramount. Certain paints, adhesives, and plastics release harmful fumes or cause skin irritation upon prolonged contact. Prioritize materials certified as non-toxic and ensure adequate ventilation during construction and wear. In the context of a “diy tinman costume,” this necessitates scrutinizing the composition of metallic-toned paints and sealant sprays.

- Vision Obscuration

The design of the headpiece must not significantly impede the wearer’s field of vision. Restricted peripheral vision increases the risk of accidents, particularly in crowded environments. Incorporating wide eyeholes or transparent panels is crucial. Within the scope of a homemade representation, this may involve modifying a helmet or hat to accommodate unobstructed sightlines.

- Ventilation Sufficiency

Adequate ventilation is essential to prevent overheating and discomfort. Enclosed headgear restricts airflow, leading to a buildup of heat and moisture. Integrate ventilation holes or channels into the design. The “diy tinman costume” headpiece, often constructed from rigid materials, requires strategic placement of these openings without compromising structural integrity.

- Secure Fastening

The headpiece must be securely fastened to prevent accidental displacement during movement. A loose-fitting headpiece can shift and obstruct vision, increasing the risk of falls or collisions. Employ adjustable straps or internal padding to ensure a snug and stable fit. Securing the “diy tinman costume” headpiece may involve attaching it to a supporting structure or using a chinstrap mechanism.

These facets of headgear safety are intrinsic to the responsible creation of any homemade costume. Neglecting these considerations elevates the risk of injury and undermines the wearer’s overall experience. Prioritizing safety ensures that the homemade representation remains a source of enjoyment rather than a potential hazard.

5. Comfort fitting

Comfort fitting represents a critical element in the creation of a durable representation. The inherent rigidity and often unconventional construction materials associated with simulating the character’s metallic form present challenges to wearer comfort. Ill-fitting components result in restricted movement, chafing, and overheating, diminishing the overall experience and potentially limiting the duration of wear. For instance, a chest plate constructed from unyielding cardboard, lacking internal padding or adjustment mechanisms, can cause significant discomfort and impede breathing, particularly during extended periods of physical activity. Proper fitting, therefore, mitigates potential negative effects and enhances the wearer’s ability to embody the character convincingly.

The practical application of comfort-fitting principles necessitates careful consideration of several factors. Internal padding, strategically placed at pressure points such as the shoulders and hips, distributes weight and minimizes friction. Adjustable straps

or closures enable a customized fit, accommodating variations in body size and shape. Furthermore, the incorporation of breathable materials, such as mesh panels in areas prone to perspiration, promotes ventilation and reduces the risk of overheating. Consider the example of creating the leg components. Rigid metal or plastic pipes might accurately simulate the character’s limbs, but without incorporating flexible joints or padded interiors, they would severely restrict movement and cause discomfort. Replacing portions with durable fabric sections could increase flexibility.

In summary, comfort fitting is not a secondary consideration but an integral component of the creative representation. The ability to move freely, breathe comfortably, and avoid chafing directly impacts the wearer’s enjoyment and the overall success. Addressing these comfort-related aspects contributes to a more authentic and engaging experience, fostering a more positive and convincing embodiment of the iconic character.

6. Design accuracy

Design accuracy in the context of a self-assembled character representation refers to the degree to which the finished product mirrors the established visual characteristics of the intended subject. Within this realm, this facet is vital because it determines the recognizability of the creation and, consequently, the overall success of the undertaking.

- Proportional Fidelity

Maintaining accurate proportions is essential for establishing visual credibility. Discrepancies in the relative size of limbs, torso, or head can distort the character’s familiar silhouette, rendering it unrecognizable. The execution of the design, therefore, necessitates careful measurement and scaling to ensure each component accurately reflects the characters established body plan. For example, an excessively large head or disproportionately short limbs detract from the design accuracy.

- Material Authenticity

The selection of materials significantly impacts the design’s authenticity. While complete adherence to realistic materials might be impractical or cost-prohibitive, choices should strive to evoke the intended textural qualities. The simulation of metallic surfaces is particularly relevant. The substitution of inexpensive, readily available materials, such as painted cardboard, requires meticulous surface treatment to mimic the sheen and texture of metal. Deviation from reasonably accurate material choices diminishes the realism of the design.

- Color Consistency

Adhering to established color schemes is crucial for immediate recognition. The use of inaccurate colors can confuse the viewer and diminish the intended visual impact. Color consistency extends beyond broad hues; it encompasses the subtle variations and gradations that contribute to a lifelike appearance. If colors are inaccurate, this detracts from the design.

- Detailed Replication

Attention to detail distinguishes a convincing representation from a crude approximation. The inclusion of specific accessories, unique design elements, and subtle visual cues reinforces the association with the intended character. Details might be specific joints or bolts.

In conclusion, design accuracy is a multifaceted consideration encompassing proportional fidelity, material authenticity, color consistency, and detailed replication. The effective synthesis of these factors significantly enhances the recognizability and visual impact of the homemade creation, contributing directly to its success.

Frequently Asked Questions

The following addresses common inquiries regarding the construction of a homemade representation of the iconic character. Answers are provided to assist in the fabrication process.

Question 1: What materials are most suitable for simulating a metallic appearance without excessive weight?

Lightweight corrugated cardboard, craft foam, and flexible aluminum sheeting offer viable options. These materials provide a suitable base for applying metallic paints or finishes, minimizing the overall weight of the ensemble. Reinforcement techniques, such as layering or the application of a rigid backing, can enhance durability without adding substantial weight.

Question 2: How can articulated joints be effectively constructed to allow for a reasonable range of motion?

Hinges, elastic straps, and flexible tubing represent effective mechanisms for creating articulated joints. The selection of the appropriate mechanism depends on the specific joint location and the desired range of motion. Careful measurement and precise assembly are crucial for ensuring proper functionality and structural integrity. Consider how an elbow bends and mimics that.

Question 3: What safety precautions should be observed during the fabrication process, particularly when using power tools or adhesives?

Eye protection, respiratory masks, and gloves are essential when working with power tools, paints, or adhesives. Adequate ventilation should be maintained to minimize exposure to harmful fumes. Power tools should be used in accordance with manufacturer instructions, and appropriate safety measures should be implemented to prevent accidents.

Question 4: How can the headgear be designed to ensure adequate ventilation and visibility without compromising the overall aesthetic?

Strategically placed ventilation holes, concealed beneath decorative elements, can promote airflow without detracting from the visual design. Wide eyeholes or transparent panels should be incorporated to provide an unobstructed field of vision. The use of lightweight materials minimizes the risk of discomfort or neck strain.

Question 5: What techniques can be employed to enhance the durability of the paint finish and prevent chipping or scratching?

Applying a primer before painting enhances adhesion and provides a uniform surface. Multiple thin coats of metallic paint offer superior coverage and durability compared to a single thick coat. A clear sealant can be applied as a final layer to protect the paint finish from scratches and abrasions. Consider if the environment affects the durability such as weather.

Question 6: How can comfort be maximized during extended wear, particularly in areas that come into direct contact with the skin?

Padding with soft materials, such as foam or fabric, at pressure points can alleviate discomfort and prevent chafing. Adjustable straps or closures allow for a customized fit, accommodating variations in body size and shape. Breathable fabrics can be incorporated to promote ventilation and reduce perspiration.

These responses highlight the practical considerations involved in the creation of a homemade representation, emphasizing the importance of safety, functionality, and aesthetic appeal.

The subsequent section will address advanced construction techniques, offering insights into complex design elements and innovative material applications.

Conclusion

The preceding discourse has explored diverse facets of the “diy tinman costume”, from foundational material considerations to intricate design and safety protocols. Emphasis has been placed on achieving a balance between aesthetic fidelity, structural integrity, and wearer comfort, crucial elements in the successful realization of a convincing homemade representation. Various techniques, materials, and construction methodologies have been presented to facilitate the fabrication process.

Effective creation requires comprehensive planning, meticulous execution, and a commitment to safety. It stands as a testament to resourcefulness and ingenuity. Future endeavors in homemade recreations may benefit from exploring advanced materials and construction techniques, further enhancing the realism and durability of such representations. This embodies a practical and artistic endeavor.