A gate designed to move horizontally along tracks through manual work, rather than swinging open on hinges. Its creation involves the application of individual craftsmanship in material selection, construction, and installation. As an illustration, homeowners might choose to construct and set up their own entrance access point to secure their property.

Such a project delivers significant advantages, including cost savings, customization, and the satisfaction of hands-on creation. Historically, gates offered security and controlled entry, evolving from basic barriers to sophisticated mechanisms. Implementing the process allows adaptation to specific site conditions and aesthetic preferences that stock gates cannot provide.

The subsequent sections will detail the materials required, the necessary tools, a step-by-step construction guide, considerations for automation, and essential safety precautions. Following that, potential challenges and troubleshooting tips will be outlined.

Tips for DIY Sliding Gate Construction

This section provides essential advice to ensure a successful and secure installation. Careful planning and execution are paramount.

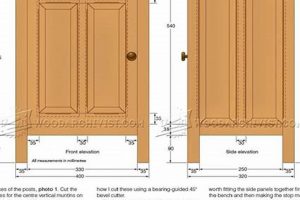

Tip 1: Precise Measurement is Crucial: Accurate measurements of the opening and available space are fundamental. This prevents issues during installation and ensures smooth operation. Document all dimensions meticulously.

Tip 2: Select Durable Materials: Choosing high-quality materials, resistant to weather and wear, extends the lifespan of the structure. Consider steel, aluminum, or treated wood for the frame and gate itself. Evaluate hardware quality.

Tip 3: Proper Post Installation: The posts provide the structural support. Securely anchoring them in concrete, ensuring they are plumb and level, is essential for stability and correct gate alignment.

Tip 4: Use Appropriate Hardware: The right rollers, tracks, and brackets ensure smooth and reliable movement. Purchase components designed for the specific weight and size of the gate. Prioritize durable, weather-resistant hardware.

Tip 5: Level Track Installation: Level installation of the track is vital for easy gate operation. Employ a level and string line to ensure the track is perfectly horizontal along its entire length. Misalignment leads to binding and premature wear.

Tip 6: Implement Safety Features: Consider incorporating safety measures like pinch guards, photoelectric sensors (if automating), and easily accessible emergency stops. This protects users and prevents accidents.

Tip 7: Plan for Drainage: Adequate drainage around the gate area prevents water accumulation, which can damage the mechanism and surrounding structure. Ensure proper grading and consider drainage solutions if necessary.

By adhering to these recommendations, the creation of a functional, secure, and long-lasting access point is significantly enhanced. The attention to detail outlined above directly impacts performance and longevity.

The following section will address common pitfalls encountered during the process, along with effective troubleshooting methods.

1. Material Durability

Material durability is paramount to the long-term functionality and structural integrity of a DIY sliding gate. The selection of appropriate materials directly influences its resistance to environmental stressors, physical wear, and potential security breaches.

- Corrosion Resistance

Materials exposed to the elements are susceptible to corrosion, which can weaken structural components and compromise functionality. Selecting materials like galvanized steel, aluminum, or powder-coated metals mitigates this risk. Untreated steel, for example, will rust quickly, shortening the gate’s lifespan and requiring frequent maintenance. Proper corrosion resistance is crucial in coastal or high-humidity environments.

- Weathering Properties

Exposure to sunlight, rain, and temperature fluctuations can degrade certain materials over time. Wood, for instance, may warp, crack, or rot if not properly treated and sealed. Similarly, some plastics become brittle under prolonged UV exposure. Opting for weather-resistant materials ensures the gate maintains its structural integrity and aesthetic appearance through changing seasons.

- Impact Resistance

A sliding gate may be subjected to accidental impacts, such as a vehicle bump or fallen debris. The material’s ability to withstand these forces without significant damage is critical. Steel and reinforced composites offer superior impact resistance compared to softer materials like wood or thin-gauge aluminum. In residential areas, a robust material safeguards against unintentional damage.

- Load-Bearing Capacity

The gate’s framework must support its own weight, as well as any additional loads imposed by wind pressure or automated operating systems. A material with insufficient load-bearing capacity may sag, bend, or even fail under stress. Steel and thick-gauge aluminum are common choices for larger gates due to their high strength-to-weight ratio. The proper load-bearing capacity is crucial for safety and operational reliability.

In summation, the selection of durable materials is not merely an aesthetic consideration; it is a fundamental aspect of designing and constructing a safe, reliable, and long-lasting DIY sliding gate. Thorough evaluation of environmental factors, potential impacts, and load requirements is essential to ensure optimal performance and minimize the need for future repairs or replacements.

2. Precise Measurements

The successful construction of a gate hinged on accurate dimensions. Dimensional inaccuracies propagate errors throughout the entire building process, negatively affecting functionality, structural integrity, and aesthetics. For instance, if the width of the opening is underestimated, the gate will not fully close, compromising security. Conversely, overestimation results in gaps, reducing privacy and allowing potential intrusion. Precise measurements are not merely a preliminary step; they are a foundational element directly impacting the final outcome.

Incorrect measurements affect the alignment of the track and rollers, causing friction, binding, and premature wear. A gate that does not roll smoothly is not only inconvenient but also increases the strain on any automated operating system, potentially leading to mechanical failures. Real-world scenarios frequently involve gates that derail or jam due to even slight miscalculations during the initial measurement phase. Furthermore, inaccurate post placement, stemming from imprecise measurements, compromises the structural stability of the entire framework, increasing the risk of collapse or failure under load. This emphasis on accuracy extends to all components, from

the gate frame to the supporting hardware.

Therefore, achieving a functional requires rigorous attention to detail in measurement. Employing appropriate tools, double-checking dimensions, and accounting for potential variations (such as uneven terrain) are critical. Overlooking the importance of accurate dimensions inevitably results in operational difficulties, structural weaknesses, and compromised security. The initial investment of time and effort in precise measurement significantly reduces the likelihood of costly rework, ensuring the gate functions effectively and reliably for its intended lifespan.

3. Smooth Operation

Achieving smooth operation in a sliding gate is a direct consequence of careful planning, precise execution, and component selection during its construction. Friction is the primary enemy. A gate designed with inadequate tolerances, misaligned tracks, or substandard rollers will inevitably exhibit operational difficulties. The relationship is causal: inadequate design and execution directly lead to increased resistance and a compromised sliding motion. The gate’s functionality diminishes proportionally to the degree of resistance encountered. Real-world examples include gates that require excessive force to open or close, make loud grinding noises, or even become completely inoperable.

Smooth operation directly impacts the lifespan of the gate and its components. Excessive force exerted during operation accelerates wear on rollers, tracks, and any automated operating system. Consequently, a sliding gate, designed and built with a focus on smooth movement, requires less maintenance and experiences fewer breakdowns. The choice of high-quality, properly lubricated rollers, coupled with perfectly level and aligned tracks, constitutes a significant investment in long-term reliability. Professional installations often emphasize precision in these areas, ensuring effortless movement and minimizing stress on the system.

Ultimately, smooth operation is not merely a desirable attribute; it is a crucial element in the overall functionality and longevity of a sliding gate. Addressing factors that impede smooth movement friction, misalignment, and substandard components is critical for realizing the gate’s intended purpose. Understanding the interdependence between construction quality and operational performance allows for a building process that prioritizes reliability, safety, and ease of use.

4. Secure Installation

The secure installation of a gate directly correlates with its capacity to fulfill its intended purpose: controlled access and property protection. A sliding gate, regardless of its aesthetic design or materials, is only as effective as its installation allows. Improper securing of the support posts, inadequate anchoring of the track, or faulty gate-to-post connections undermine the entire structure’s integrity, transforming a potential security barrier into a vulnerable point of entry. A poorly installed gate is easily breached, circumventing any deterrent effect it might otherwise provide. Real-world examples demonstrate scenarios where improperly secured gates were readily forced open, rendering them useless against unauthorized access.

The practical significance of a secure installation extends beyond preventing intrusion; it also ensures the gate’s operational safety and longevity. Incorrect installation causes undue stress on the operating mechanism, accelerating wear and tear. This results in frequent malfunctions, requiring costly repairs and potentially creating hazardous conditions. For instance, a gate that derails from its track due to faulty installation poses a safety risk, especially if automated. Furthermore, the stability of the support structure directly depends on the installation’s integrity. Unsecured or poorly anchored posts are susceptible to shifting, leaning, or even collapsing under the weight of the gate, particularly during adverse weather conditions. Properly secured components distribute the gate’s load effectively, maintaining its structural integrity and ensuring safe operation over time.

In conclusion, securing the gate constitutes a critical component of its overall functionality. The structural integrity, operational reliability, and security effectiveness of a gate are all directly proportional to the quality of its installation. While aesthetic considerations and material selection contribute to the gate’s overall value, a compromised installation negates these benefits. Therefore, prioritizing secure installation is essential for maximizing the gate’s intended purpose, ensuring both its effectiveness as a security barrier and its long-term operational safety.

5. Automated Features

The incorporation of automated features transforms a manually operated sliding gate into a remotely controlled access system. This integration demands a heightened awareness of electrical principles, safety protocols, and mechanical interfacing. While offering convenience and enhanced security, automated features require careful planning and precise execution to ensure safe and reliable operation within a homemade sliding gate context.

- Motor Selection and Installation

The motor serves as the driving force behind automated operation. Its selection hinges on the gate’s weight, length, and intended usage frequency. An undersized motor risks premature failure, while an oversized motor consumes unnecessary power. Proper installation involves secure mounting, accurate wiring, and precise adjustment of torque settings. Real-world scenarios often involve improperly installed motors that generate excessive noise, exhibit erratic movements, or fail to operate under load.

- Control Systems and Remote Access

The control system manages the gate’s operation, enabling remote access via keypads, remote controls, or smartphone applications. These systems require secure wiring, proper programming, and robust security protocols to prevent unauthorized access. Inadequately secured control systems are vulnerable to hacking, potentially compromising property security. Effective implementation includes strong passwords, encrypted communication channels, and physical protection of the control unit.

- Safety Sensors and Obstruction Detection

Safety sensors are crucial for preventing accidents and damage during automated operation. Photoelectric sensors, for example, detect obstructions in the gate’s path, halting movement to avoid collisions. These sensors require precise alignment and regular maintenance to ensure reliable performance. Systems lacking adequate obstruction detection mechanisms pose a significant safety hazard, particularly in residential environments with children or pets.

- Power Supply and Electrical Safety

Automated sliding gates necessitate a dedicated power supply capable of delivering consistent voltage and amperage. Adherence to electrical safety codes is paramount to prevent electrical shocks, fires, and equipment damage. Proper grounding, circuit protection, and weatherproof enclosures are essential for safe and reliable operation. Substandard electrical installations pose a serious risk to both the gate operator and individuals i

n the vicinity.

Integrating automated features into the do-it-yourself project extends beyond mere convenience; it significantly impacts the overall safety and security. The successful implementation requires a synthesis of mechanical skills, electrical knowledge, and a thorough understanding of safety protocols. While offering significant advantages, automated systems demand a higher level of expertise and responsibility compared to manually operated gates. Failure to address these factors can lead to compromised security, operational failures, and potential hazards.

Frequently Asked Questions

This section addresses common inquiries regarding the construction, installation, and maintenance of such structures. The answers provided aim to offer clarity and guidance based on established practices.

Question 1: What are the primary advantages of constructing a gate yourself?

The principal benefits include cost reduction compared to professional installation, customization to specific site requirements, and the acquisition of hands-on construction experience.

Question 2: What are the essential materials required for the frame?

Common materials include steel, aluminum, and treated wood. The choice depends on budget, desired aesthetic, and the required strength and weather resistance.

Question 3: What tools are indispensable for this project?

Essential tools encompass a measuring tape, level, welding equipment (if using steel), saw, drill, concrete mixer (for post installation), and appropriate safety gear.

Question 4: How deep should the support posts be set into the ground?

The recommended depth is typically one-third the total post length, set in concrete to ensure stability and resistance to wind loads. Local building codes should be consulted for specific requirements.

Question 5: What are the critical safety precautions to consider during construction?

Wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and hearing protection is vital. Adhering to safe welding practices (if applicable) and implementing secure lifting techniques are also essential.

Question 6: How does climate influence material selection?

In coastal regions, corrosion-resistant materials such as galvanized steel or aluminum are preferred. In areas with heavy snowfall, the gate design must accommodate the increased weight and potential ice accumulation.

In summary, constructing a sliding gate demands careful planning, the selection of appropriate materials, and strict adherence to safety guidelines. Addressing these frequently asked questions provides a foundational understanding of the critical aspects involved.

The next section will provide troubleshooting advice for common issues encountered during operation.

Conclusion

The preceding discussion explored the multifaceted considerations involved in the construction. From material selection and precise measurements to secure installation and the integration of automated features, each element plays a crucial role in determining the final outcome. Furthermore, the safety and operational longevity are directly proportional to the diligence applied throughout the construction process.

Ultimately, undertaking such a project requires careful assessment of one’s skills, resources, and commitment. While the potential for cost savings and customization is significant, neglecting the fundamental principles outlined herein carries substantial risks. The information provided aims to empower informed decision-making and promote responsible implementation, ensuring the final product meets both functional and safety requirements. Future development might focus on smart technology integration and sustainable material options, ensuring its continued relevance and adaptation to evolving needs.