A homemade outfit replicating the thrill of an amusement park ride allows individuals to creatively express their enthusiasm for these attractions through wearable art. Such projects often involve the utilization of readily available materials, imaginative construction techniques, and a focus on conveying the visual and kinetic elements associated with steep inclines, rapid descents, and winding tracks. As an illustration, one might construct a miniature representation of a looping track around their body, complete with a small cart or figurine acting as the “rider.”

The creation of such apparel offers several advantages. It promotes resourcefulness by encouraging the repurposing of everyday items into something extraordinary. Furthermore, it serves as an engaging activity that fosters creativity and problem-solving skills. Historically, costumes of this nature exemplify human ingenuity in transforming commonplace experiences into tangible expressions of joy and entertainment. The act of building these garments is itself a rewarding endeavor that culminates in a unique form of self-expression.

The subsequent discussion will delve into specific design considerations, material selections, and construction methodologies applicable to crafting a visually compelling and structurally sound representation. This will include strategies for achieving both aesthetic appeal and wearer comfort, as well as methods for incorporating interactive elements to enhance the immersive experience.

Essential Construction Guidelines

The following provides crucial advice to ensure the successful creation of the themed attire. Diligent planning and precise execution are paramount.

Tip 1: Prioritize Structural Integrity: A robust framework is essential. Consider the load-bearing points and use durable materials, such as PVC pipe or sturdy cardboard, to support the design’s weight and prevent collapse. Reinforce joints with strong adhesives and consider internal supports.

Tip 2: Emphasize Safety and Comfort: Sharp edges and protruding elements pose hazards. Round off corners, pad exposed areas, and ensure freedom of movement within the outfit. Select lightweight, breathable materials for the base garment to mitigate overheating.

Tip 3: Plan for Portability and Storage: Complex designs may be difficult to transport and store. Consider modular construction, allowing for disassembly into smaller components. This facilitates both transportation and storage when not in use.

Tip 4: Incorporate Dynamic Elements Strategically: Simulated motion enhances the realism. Integrate features such as manually operated “cars” or flashing lights. However, prioritize stability and balance; avoid elements that could compromise the wearer’s stability.

Tip 5: Optimize Visual Appeal through Texturing and Color: Paint and textural elements significantly impact the presentation. Employ vibrant colors to emulate the visual excitement. Use reflective materials to simulate motion and enhance visibility in low-light conditions.

Tip 6: Measure Accurately and Prototype Before Final Assembly: Precise measurements are essential to ensure proper fit and functionality. Construct a small-scale prototype to test design elements and identify potential issues before committing to full-scale construction. Adjust designs as necessary.

These guidelines stress the importance of structural soundness, wearer well-being, and ease of handling. Meticulous attention to detail is essential for crafting a successful representation.

Subsequent sections will address potential challenges encountered during construction and offer solutions to common problems. This proactive approach minimizes frustration and maximizes the likelihood of a successful outcome.

1. Engineering Stability

Engineering stability constitutes a foundational element in the successful fabrication of themed attire. It ensures the structure’s integrity, preventing collapse or deformation under its own weight and the stresses of movement. Within the context, a failure to adequately address engineering stability results in an unsafe and visually unconvincing outcome.

- Load Distribution

Load distribution concerns how the weight of the structure is supported and transferred to the wearer. An unstable design concentrates weight on certain points, causing discomfort and potentially structural failure. Proper load distribution uses a network of support structures to spread the weight evenly across the wearer’s body, reducing strain and enhancing stability. This might involve employing a backpack-like harness for larger designs or strategically placed internal supports.

- Material Selection and Strength

The choice of materials dictates the structural capacity of the outfit. Lightweight materials like cardboard are appropriate for smaller or primarily decorative elements. However, larger, load-bearing components require materials with higher tensile strength, such as PVC pipe, metal rods, or reinforced plastics. Material selection considers both weight and resistance to bending or breaking. Improper selection can lead to structural weaknesses and collapse under stress.

- Joint Integrity

Joints, where different structural elements connect, represent potential points of failure. The method of joining components, whether through adhesives, fasteners, or welding, directly impacts the overall stability. Weak joints compromise the entire structure, regardless of the strength of individual components. Proper joint design includes considering the forces acting on the joint and employing connection methods that adequately resist those forces. For example, using threaded connections instead of glue alone for high-stress joints.

- Center of Gravity Management

The center of gravity affects balance and stability. A high center of gravity makes the creation top-heavy and prone to tipping, while a low center of gravity enhances stability. Designers must consider the distribution of weight and the location of the center of gravity relative to the wearer’s base of support. Strategically positioning heavier components lower in the structure lowers the center of gravity, increasing stability and reducing the risk of imbalance.

In summation, neglecting engineering stability during the design and construction phase undermines the entire creative effort. A well-engineered construction ensures safety, longevity, and a more believable representation of the intended amusement park ride.

2. Material Selection

Material selection forms a cornerstone in crafting a successful wearable amusement park ride replica. The choice of materials directly influences the structure’s durability, weight, aesthetic qualities, and wearer comfort. Consequently, a lack of

careful consideration regarding material properties can lead to structural instability, discomfort, and a diminished visual impact. For example, substituting lightweight cardboard for sturdier PVC piping in load-bearing elements directly compromises structural integrity, potentially leading to collapse. Conversely, prioritizing solely aesthetics without considering weight results in an unwieldy creation, impacting the wearer’s mobility and comfort. The interdependence between structural requirements, visual design, and usability necessitates a balanced approach to material selection.

Specific material choices offer distinct advantages and disadvantages. Expanded polystyrene foam, while lightweight and easily shaped, lacks the durability required for frequently handled components. PVC piping, conversely, provides structural strength and weather resistance but presents challenges in shaping complex curves. Fabric choices influence breathability and aesthetic presentation; heavy canvas provides durability but can lead to overheating, whereas lighter fabrics may lack structural support. The successful embodiment balances the trade-offs, utilizing each material’s properties strategically. For example, combining a PVC pipe framework with a shaped foam exterior allows for both structural integrity and detailed visual representation. Integrating LED lighting, while enhancing visual dynamism, necessitates consideration of power source placement and wire management to maintain structural integrity and wearer safety.

In conclusion, the material selection process determines the feasibility and ultimate quality of a theme creation. A comprehensive understanding of material properties, structural requirements, aesthetic considerations, and wearer comfort is vital. By carefully balancing these factors, creators can transform conceptual designs into tangible, durable, and visually impressive representations. Ignoring this key aspect increases the likelihood of structural failures, diminished visual appeal, and ultimately, a disappointing outcome.

3. Visual dynamism

Within the realm of wearable amusement park ride representations, visual dynamism constitutes a crucial factor in conveying the essence of the experience. It captures the perceived movement, speed, and excitement associated with the actual rides, translating these qualities into a visually engaging three-dimensional form.

- Color Palette and Contrast

Strategic use of color significantly contributes to the perception of motion. Employing vibrant, contrasting colorsfor example, bright reds and yellows against deep blues or blacksemulates the visual intensity associated with high-speed movement. Color blocking techniques, wherein large areas of contrasting colors are juxtaposed, further enhance the illusion of motion. In such wearable art, the strategic placement of these colors can mimic the blur experienced during rapid acceleration and deceleration.

- Motion Simulation via Design Elements

Design elements such as spiraling lines, angled planes, and overlapping shapes can simulate movement. Incorporating these elements onto the surfaces of the construction imitates the visual distortions and perceived speed of a real ride. For instance, angled panels affixed to the exterior surface, strategically positioned to suggest acceleration or descent, augment the impression of velocity. The thoughtful arrangement of these visual cues contributes to a sense of kinetic energy.

- Integrated Lighting Effects

The incorporation of lighting, particularly dynamic lighting effects, enhances the visual dynamism of the wearable piece. Using flashing LEDs, chasing lights, or color-shifting illumination amplifies the impression of speed and motion. For example, strategically placed LED strips along the “track” of the costume can simulate the movement of a cart, enhancing the sense of realism. The selection of lighting color and intensity further refines the visual portrayal.

- Textural Variety and Reflective Surfaces

Introducing variations in texture and incorporating reflective materials increases visual interest and simulates the play of light during motion. Reflective surfaces, such as metallic paint or mirrored elements, catch and scatter light, creating a sense of movement and changing perspectives as the wearer moves. Textured surfaces, achieved through layering different materials or applying paint techniques, add depth and complexity, further enhancing the visual impression.

The combined effect of color, design elements, lighting, and texture transforms the wearable structure from a static representation into a dynamic and engaging visual experience. These elements, when thoughtfully integrated, effectively convey the intended sensations associated with an amusement park ride, elevating the creation beyond a mere costume into an immersive piece of wearable art. The deliberate application of these visual techniques underscores the connection between static form and simulated motion.

4. Wearer comfort

The relationship between wearer comfort and the construction directly influences the success and practicality of the finished product. The inherent rigidity and potentially unwieldy nature associated with replicating the complex structures presents significant challenges to mobility and sustained wearability. Failure to address comfort considerations translates to a costume that, while visually impressive, remains impractical for extended use, ultimately detracting from the overall experience. Examples of discomfort manifest in restricted movement, chafing from rough materials, excessive weight bearing on specific body parts, and inadequate ventilation, leading to overheating. Proper consideration, conversely, yields a wearable piece that, while ambitious in design, permits relative freedom of movement and prolonged use without undue physical strain.

Achieving adequate comfort necessitates meticulous attention to several design aspects. The selection of lightweight and breathable materials for the base structure minimizes overall weight and allows for air circulation. Padding and cushioning applied to contact points, such as shoulder straps and interior framework elements, mitigate chafing and pressure. Furthermore, the strategic distribution of weight across the body through a harness system or internal support structure minimizes strain on specific areas, such as the shoulders or back. Careful consideration to joint articulation permits a greater range of motion, enabling the wearer to navigate spaces and perform basic movements without undue restriction. For instance, articulated joints in the arms or legs, constructed with flexible materials, accommodate bending and flexing, improving ease of movement. The inclusion of ventilation systems, such as strategically placed mesh panels or internal fans, facilitates airflow, reducing heat buildup and enhancing breathability.

In conclusion, wearer comfort represents a crucial, often overlooked, factor in the construction of a wearable themed creation. Addressing comfort concerns through careful material selection, strategic weight distribution, and attention to freedom of movement significantly enhances the user experience and overall success of the project. By prioritizing comfort alongside visual appeal, the designer can transform what might otherwise be an impractical spectacle into a wearable piece of art. Neglecting comfort consideratio

ns, however, renders even the most visually stunning construction unsustainable for anything beyond brief display, limiting its practical value and diminishing its impact.

5. Portability design

Portability design addresses the inherent challenge of transporting and storing structures of significant size and complexity. Within the context, the physical dimensions and intricate construction often pose logistical hurdles, requiring careful consideration of disassembly, storage space, and ease of reassembly. An inadequately designed wearable model may prove impractical for transport to events or storage between uses, diminishing its overall value.

- Modular Construction

Modular construction involves dividing the structure into smaller, self-contained units that can be easily detached and reassembled. This approach simplifies transportation by reducing the overall dimensions of individual components. For example, a large track can be designed as several sections that connect with fasteners, allowing for compact storage and easier handling. This facilitates transport in standard vehicles and reduces storage space requirements.

- Collapsible Elements

Collapsible elements utilize hinges, folding mechanisms, or flexible materials to reduce the structure’s size during transport. Components, such as support struts or decorative features, can be designed to fold inward or collapse against the main body. An example involves a track support system that folds flat against the wearer’s body, reducing bulk and streamlining the profile for transportation and storage. This minimizes the occupied volume and mitigates potential damage during handling.

- Lightweight Materials

The selection of lightweight materials minimizes the overall weight of the costume, easing transport and reducing physical strain on the wearer during movement and setup. Substituting heavy materials, such as solid wood, with lighter alternatives like corrugated plastic or foam core reduces the overall burden. For instance, using a lightweight PVC frame instead of a metal frame significantly decreases weight without sacrificing structural integrity. This makes the costume easier to carry, transport, and maneuver, particularly over extended distances or periods.

- Integrated Storage Solutions

Integrating storage compartments or dedicated carrying cases into the design facilitates the organization and protection of individual components during transport. Dedicated compartments within the structure can accommodate smaller parts, such as fasteners, lighting elements, or spare parts. The design might also include a custom-fitted carrying case for the entire ensemble or its modular components. This not only protects the materials from damage but also simplifies packing and unpacking, streamlining the setup process at events.

In conclusion, portability design represents a critical, albeit often overlooked, element in the successful creation of these types of costumes. By incorporating modular construction, collapsible elements, lightweight materials, and integrated storage solutions, creators can mitigate the logistical challenges associated with large and complex structures, ensuring that the finished product remains practical for both transport and storage. This attention to portability expands the usability and longevity of the structure, making it a more valuable and versatile creation.

Frequently Asked Questions

The following addresses common inquiries and provides clarification regarding various aspects of constructing themed attire.

Question 1: What materials are most suitable for constructing a durable frame?

PVC piping, metal rods, and reinforced plastics provide structural integrity. The specific choice depends on the design’s weight and complexity, with PVC offering a balance of strength and affordability.

Question 2: How is stability maintained during wear?

Weight distribution is key. A harness system or internal supports that distribute the weight evenly across the torso minimize strain and prevent tipping.

Question 3: How can the impression of motion be effectively conveyed?

Dynamic lighting, strategic use of color contrast, and the incorporation of angled or spiraling design elements are important considerations. Reflective surfaces also enhance the illusion of movement.

Question 4: What safety precautions should be taken during construction and wear?

Sharp edges should be rounded and protruding elements minimized. Padding should be applied to contact points. Ensuring unrestricted movement within the attire is essential for preventing accidents.

Question 5: How is transportability addressed for larger designs?

Modular construction, wherein the structure disassembles into smaller components, significantly simplifies transportation and storage. Collapsible elements further reduce the overall size during transit.

Question 6: How can wearer comfort be maximized?

Lightweight, breathable materials should be utilized for the base garment. Adequate ventilation, achieved through mesh panels or internal fans, is crucial for preventing overheating.

In summary, successful fabrication depends on a holistic approach encompassing structural integrity, visual dynamism, safety, portability, and wearer comfort.

The concluding section will provide a concise overview of the core principles and best practices.

Conclusion

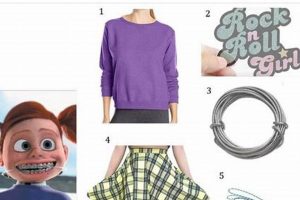

The preceding exposition has explored the multifaceted considerations inherent in creating a “roller coaster diy costume”. This undertaking demands a synthesis of engineering principles, artistic vision, and practical considerations for both wearer safety and logistical feasibility. The successful execution hinges upon a comprehensive understanding of material properties, structural design, visual representation of motion, and ergonomic integration.

Continued innovation within this niche relies on embracing advancements in lightweight materials, refining modular construction techniques, and prioritizing wearer comfort without sacrificing visual impact. The future development of similar projects should focus on creating immersive experiences that are both visually compelling and practically wearable, encouraging further exploration of the intersection between art, engineering, and personal expression.