The creation of customized surfaces designed specifically for tabletop gaming constitutes a significant area of interest for hobbyists and dedicated gamers. This endeavor typically involves individual design and construction, allowing for adaptation to specific needs and spatial constraints. Examples include crafting a playing surface with integrated storage for game components or incorporating features such as recessed areas to contain dice rolls.

Constructing a specialized gaming surface offers advantages such as tailored dimensions, personalized aesthetics, and cost-effectiveness compared to commercially available options. Historically, individuals have modified existing furniture or built from scratch to optimize the gaming experience, reflecting a desire for enhanced functionality and a more immersive environment. The resultant customized tables often become centerpieces for social gatherings and dedicated gaming spaces.

The subsequent discussion will delve into the considerations involved in planning a personalized gaming area, various construction methods, and potential design features. Furthermore, it will explore the tools and materials necessary for successful project completion, and provide guidance on troubleshooting common challenges encountered during the construction process.

Board Game Table DIY

Successful creation of a custom gaming surface necessitates careful planning and execution. The following guidelines offer practical advice to optimize the building process and ensure a functional, durable final product.

Tip 1: Precise Measurement and Planning: Accurate measurements of the intended playing area are crucial. Detailed blueprints, incorporating dimensions of all components, minimize errors and material waste. Careful consideration of leg placement and overall table stability is essential during the planning phase.

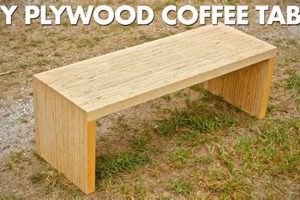

Tip 2: Material Selection and Durability: Opting for high-quality materials, such as hardwood plywood or solid wood for the frame, guarantees long-term durability. The playing surface material should be smooth, resistant to scratches, and easy to clean. Wood selection should factor in desired aesthetic and stain acceptance properties.

Tip 3: Secure Joinery Techniques: Employing robust joinery methods, such as mortise and tenon joints or pocket screws with wood glue, reinforces the table’s structural integrity. Properly executed joints prevent warping, sagging, and instability over time.

Tip 4: Leveling and Surface Treatment: Ensuring a perfectly level playing surface is paramount. Use shims or adjustable feet to compensate for uneven flooring. Apply a durable finish, such as polyurethane or varnish, to protect the wood from spills and scratches. Multiple thin coats are preferable to a single thick coat.

Tip 5: Component Integration Considerations: When incorporating features like cup holders, dice trays, or recessed playing areas, integrate these components seamlessly into the design. Securely fasten these elements to the table frame to prevent movement or detachment.

Tip 6: Consider lighting: Integrate lighting strategically to eliminate shadows and enhance the playing experience. LED strips can be embedded within the table’s frame or underneath the play surface. Ensure proper wiring and safety precautions when working with electrical components.

Tip 7: Fabric Selection: If using fabric on the playing surface, select a durable, stain-resistant material like felt, speed cloth, or billiard cloth. Properly adhere the fabric to the surface, ensuring a smooth, wrinkle-free finish. Avoid fabrics that easily pill or snag.

Adherence to these recommendations enhances the longevity and functionality of the finished product, resulting in a customized gaming surface tailored to specific needs.

The subsequent discussion will address advanced design considerations and specialized features applicable to gaming surface construction.

1. Design Blueprinting

Design blueprinting constitutes the foundational stage in any successful personalized gaming surface project. It establishes the framework for all subsequent construction phases, dictating dimensions, material requirements, and integrated features. Without a meticulously crafted blueprint, the project risks inconsistencies, structural weaknesses, and functional limitations.

- Dimensional Accuracy

Dimensional accuracy, enabled by detailed blueprinting, guarantees that the resultant gaming surface conforms to the intended spatial constraints. Accurate measurements prevent miscalculations during material procurement and construction, minimizing waste and rework. Precise dimensions are essential for ensuring the table fits within the designated gaming area and accommodates intended seating arrangements.

- Material Optimization

Blueprinting facilitates efficient material utilization by specifying exact quantities and dimensions of all components. By delineating individual pieces, the blueprint aids in optimizing material layout during cutting, reducing waste and minimizing costs. This proactive approach also ensures consistent material quality across all facets of the build.

- Feature Integration Planning

Design blueprints are crucial for the effective integration of supplemental features, such as cupholders, dice trays, and LED lighting systems. The blueprint provides a visual representation of these features, detailing their placement, dimensions, and connection points. Careful feature planning ensures seamless integration and prevents structural conflicts during construction.

- Structural Integrity Assessment

The blueprint serves as a tool for evaluating the table’s structural integrity prior to construction. By analyzing the design, potential weak points can be identified and reinforced. This proactive assessment reduces the risk of structural failure, ensuring the finished product is stable and durable. The blueprint also aids in determining optimal jointing techniques and material thicknesses to maximize load-bearing capacity.

In essence, comprehensive design blueprinting transforms the abstract concept of a gaming surface into a tangible, executable plan. By addressing dimensional accuracy, material optimization, feature integration, and structural integrity, the blueprint streamlines the construction process and enhances the likelihood of a successful, functional, and aesthetically pleasing final product.

2. Material Sourcing

Material sourcing constitutes a critical phase within the construction of customized gaming surfaces. The selection of materials directly impacts the structural integrity, aesthetic qualities, and overall longevity of the finished product. Effective material sourcing strategies contribute significantly to project success.

- Wood Selection and Availability

The selection of wood for the frame and playing surface influences the table’s stability and visual appeal. Hardwoods, such as maple or oak, offer superior strength and durability, while softwoods, such as pine, provide a more economical alternative. Local availability affects cost and project timelines. Sustainably sourced lumber is increasingly favored for environmental considerations.

- Fasteners and Hardware

Fasteners, including screws, bolts, and nails, are essential for joining components and ensuring structural soundness. High-quality hardware, such as hinges, latches, and drawer slides, enhances functionality and usability. Corrosion-resistant materials are recommended for long-term durability. Improper fastener selection can compromise joint strength and overall stability.

- Surface Materials

The choice of playing surface material impacts gameplay and aesthetic appeal. Felt, speed cloth, and neoprene offer different levels of friction and texture. Laminates and veneers provide a durable, easy-to-clean surface. Material selection should consider resistance to spills, scratches, and wear. Specific gaming needs may dictate material preferences.

- Finishes and Adhesives

Finishes, such as stains, varnishes, and polyurethanes, protect the wood from moisture and enhance its appearance. Adhesives, including wood glue and epoxy, are crucial for creating strong, permanent bonds. Compatibility between finishes and adhesives is essential for optimal results. Low-VOC (volatile organic compound) options are preferred for health and environmental safety.

The integration of appropriate materials directly influences the functionality and lifespan of the gaming surface. A strategic approach to material sourcing, factoring in availability, cost, durability, and aesthetic considerations, optimizes the construction process and yields a high-quality, customized gaming environment. In contrast, compromises in material quality can significantly detract from the overall value and longevity of a gaming surface project.

3. Joint Construction

Joint construction, the methods by which individual components are connected to form a cohesive structure, represents a foundational element in the creation of durable and functional gaming surfaces. The selection and execution of appropriate jointing techniques directly influence the stability, load-bearing capacity, and overall lifespan of the table.

- Mortise and Tenon Joints

Mortise and tenon joints, a traditional woodworking method, provide exceptional strength and resistance to racking forces. This technique involves creating a projection (tenon) on one piece of wood that fits precisely into a corresponding hole (mortise) on another. Examples include connecting table legs to the frame or joining frame members. Their effectiveness stems from the large surface area for glue adhesion and mechanical interlocking, making them suitable for high-stress areas.

- Dovetail Joints

Dovetail joints, characterized by interlocking wedge-shaped projections, offer superior resistance to tensile forces. These joints are often employed in drawer construction and for attaching side panels to a table frame. Their inherent mechanical strength eliminates the need for fasteners in many applications, contributing to a clean aesthetic and long-term stability.

- Pocket Screw Joints

Pocket screw joints, a more modern approach, utilize angled screws driven into pre-drilled holes to create strong, hidden connections. This technique is well-suited for assembling frame components and attaching table tops. Their advantage lies in ease of execution and versatility, making them accessible to woodworkers with varying skill levels. However, the strength is dependent on screw size and material density.

- Butt Joints with Reinforcements

Butt joints, the simplest form of joinery where two pieces of wood are butted together, require reinforcement to achieve adequate strength. This can be accomplished using dowels, biscuits, or metal fasteners. Applications include connecting frame members or attaching edge banding. While less robust than other methods, butt joints with appropriate reinforcement can be suitable for low-stress areas or in conjunction with other jointing techniques.

The successful application of these joint construction techniques is intrinsically linked to the overall success of a “board game table diy” project. A well-constructed joint not only ensures the structural integrity of the gaming surface but also contributes to its aesthetic appeal and long-term usability. Conversely, poorly executed joints can lead to instability, premature failure, and a compromised gaming experience.

4. Surface Finishing

Surface finishing represents a critical stage in the construction of custom gaming surfaces, directly influencing both the aesthetic appeal and the functional longevity of the finished product. The choice of finishing materials and application techniques determines the table’s resistance to wear, moisture, and spills, all factors inherent in typical gaming scenarios. Inadequate surface finishing can lead to premature deterioration of the underlying wood, fabric, or composite materials, resulting in compromised gameplay and a reduced lifespan of the gaming surface.

The selection of an appropriate finish depends on various factors, including the type of material used for the playing surface, the desired level of sheen, and the anticipated frequency of use. For wooden surfaces, options range from traditional varnishes and lacquers to more durable polyurethanes and epoxies. Fabric surfaces may require protective coatings to resist stains and moisture. The application method, whether brushing, spraying, or rolling, significantly impacts the uniformity and smoothness of the final finish. Proper surface preparation, including sanding and cleaning, is essential for achieving optimal adhesion and a flawless appearance. For example, applying multiple thin coats of polyurethane to a wooden gaming table provides greater protection against scratches and spills than a single thick coat, enhancing durability and maintaining the aesthetic quality over time.

In summary, surface finishing is an indispensable component of any successful “board game table diy” endeavor. It provides a protective barrier against environmental factors, enhances the visual appeal of the gaming surface, and contributes significantly to its long-term usability. A thorough understanding of the available finishing materials, application techniques, and surface preparation methods is crucial for achieving a durable, aesthetically pleasing, and functional gaming surface that can withstand the rigors of regular use. Challenges may arise from selecting incompatible finishes or improper application techniques, highlighting the importance of research and careful execution. The selection of an appropriate finish ultimately ensures the enjoyment and longevity of the customized gaming environment.

5. Feature Integration

The integration of specialized features into self-constructed gaming surfaces significantly enhances functionality and user experience. Strategic implementation of components tailored to specific gaming needs differentiates these tables from conventional furniture, optimizing gameplay and organization.

- Integrated Lighting Systems

Incorporating LED lighting within the table structure minimizes glare and shadow interference during gameplay. Strategically positioned lighting enhances visibility of game components, reducing eye strain and improving the overall immersive experience. Examples include recessed lighting around the playing surface perimeter or adjustable spotlights focused on specific game zones. Proper wiring and heat dissipation are essential for safety and longevity.

- Customizable Storage Solutions

Integrating storage compartments beneath the playing surface or within the table frame allows for organized storage of game components, dice, and player accessories. This reduces clutter and minimizes the need for external storage solutions. Examples include drawers with dividers, shelving units, or recessed compartments for storing game boxes. Efficient storage enhances setup and teardown processes, contributing to a streamlined gaming experience.

- Modular Playing Surface Components

Implementing a modular playing surface enables adaptable configurations tailored to various game types and player counts. Interchangeable tiles or inserts allow for rapid reconfiguration, accommodating different game formats. Examples include reversible tiles with different textures or patterns, modular sections for expanding or contracting the playing area, or inserts for specific game components. Modularity enhances the versatility of the gaming surface, adapting to a wide range of gaming needs.

- Integrated Cup Holders and Accessory Mounts

Incorporating cup holders and accessory mounts prevents spills and provides convenient access to drinks, dice, and other gaming peripherals. Strategically positioned cup holders minimize the risk of accidental spills onto the playing surface. Accessory mounts can accommodate dice towers, card holders, or digital devices. This enhances player comfort and convenience, promoting a more immersive and focused gaming experience.

The strategic integration of these features transforms a basic gaming surface into a highly functional and personalized gaming environment. Thoughtful consideration of individual gaming preferences and needs is crucial for optimizing feature selection and implementation, maximizing the utility and enjoyment derived from the self-constructed gaming surface.

Frequently Asked Questions

The following section addresses common inquiries regarding the construction of customized gaming surfaces. Information presented aims to clarify fundamental aspects and mitigate potential challenges.

Question 1: What is the minimum recommended size for a gaming surface intended to accommodate a variety of board games?

A playing area of 4 feet by 6 feet (1.2 meters by 1.8 meters) is generally considered the minimum size to accommodate most standard board games comfortably. This dimension provides sufficient space for components, player boards, and card layouts. Adjustments may be necessary based on specific gaming preferences and the size of commonly played games.

Question 2: Which wood type provides the optimal balance of cost, durability, and workability for constructing a gaming surface frame?

Hardwood plywood, specifically birch or maple, typically offers a favorable compromise between cost, durability, and ease of machining. Solid hardwoods, while providing superior strength, often entail higher material costs and require specialized woodworking tools. Pine, a softwood, is more affordable but may lack the necessary rigidity for larger table frames.

Question 3: What are the essential tools required to construct a gaming surface from scratch?

Fundamental tools include a table saw or circular saw, a power drill with various drill bits, a sander, measuring tools (tape measure, level, square), clamps, and safety equipment (eye protection, hearing protection). Additional specialized tools, such as a router or jointer, may be necessary for advanced joinery techniques.

Question 4: How can one ensure a perfectly level playing surface to prevent game components from sliding unintentionally?

Employing a carpenter’s level is critical throughout the construction process. Shims or adjustable feet can be used to compensate for uneven flooring. A self-leveling compound may be applied to the playing surface to achieve a perfectly flat plane before applying the final finish.

Question 5: What is the recommended type of fabric for covering a recessed gaming surface, and how should it be adhered?

Durable, low-pile fabrics such as felt, speed cloth, or billiard cloth are commonly used. Adhesion should be achieved using spray adhesive designed for fabric, applied in thin, even coats to both the fabric and the recessed surface. Stretching the fabric tautly during application prevents wrinkles and ensures a smooth playing surface.

Question 6: How can lighting be integrated into a gaming surface to minimize glare and shadows?

Recessed LED lighting systems, positioned around the perimeter of the playing surface, provide uniform illumination with minimal glare. Dimmable lighting controls allow for adjusting the brightness to suit different gaming environments. Care should be taken to conceal wiring and ensure proper ventilation to prevent overheating.

Careful planning and meticulous execution are paramount when undertaking a gaming surface construction project. Consideration of these frequently asked questions can mitigate common pitfalls and contribute to a successful outcome.

The following section will provide practical considerations for maintaining and enhancing the gaming surface.

Conclusion

The preceding discussion explored the multifaceted aspects inherent in the creation of customized gaming surfaces. From initial design and material selection to intricate joint construction, meticulous surface finishing, and the strategic integration of supplementary features, each phase demands careful consideration to ensure a functional and aesthetically pleasing outcome. Successful execution directly influences the durability, usability, and overall gaming experience provided by the finished product. Understanding of these critical components is essential for any individual undertaking such a project.

The pursuit of a personalized gaming environment through the construction of a dedicated table requires a commitment to precision and attention to detail. A well-executed gaming surface not only enhances recreational activities but also serves as a testament to craftsmanship and dedication. The insights provided serve as a foundation for informed decision-making and facilitate the realization of a bespoke gaming sanctuary.