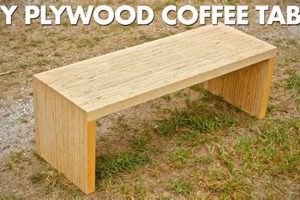

The act of independently constructing a central living room surface from timber or manufactured wood products constitutes a practical application of woodworking skills. This process allows individuals to create a bespoke furniture piece tailored to specific dimensions, aesthetic preferences, and functional needs, typically involving techniques such as measuring, cutting, joining, and finishing. For example, an individual might utilize reclaimed lumber to construct a rustic-style surface for displaying books and beverages.

Engaging in this activity offers numerous advantages, ranging from cost savings compared to purchasing pre-made furniture to the inherent satisfaction of creating a tangible object. The process also allows for personalization and customization not readily available in mass-produced items. Historically, the ability to craft furniture was a fundamental skill, and this contemporary iteration provides a connection to that tradition while fostering resourcefulness and problem-solving abilities. The resulting object reflects individual skill and design choices, enhancing the unique character of a living space.

The subsequent sections will explore various aspects relevant to this creative pursuit, including design considerations, material selection, essential tools and equipment, step-by-step construction methodologies, and appropriate finishing techniques to ensure a durable and visually appealing final product.

Essential Guidance for Wood Surface Construction

The following recommendations provide valuable insights to ensure a successful and satisfying construction experience, focusing on durability, aesthetics, and structural integrity.

Tip 1: Precise Measurement and Planning: Prior to initiating any cutting or assembly, thoroughly measure the intended space and create a detailed plan. This includes accounting for material thickness, joinery methods, and desired overall dimensions. Accurate planning minimizes errors and material waste.

Tip 2: Quality Material Selection: Opt for lumber or manufactured wood products appropriate for the intended use. Consider factors such as wood species, grade, moisture content, and resistance to wear and tear. Proper material selection contributes significantly to the finished product’s longevity and aesthetic appeal. For example, hardwoods like oak or maple are preferable for high-traffic areas.

Tip 3: Secure and Appropriate Joinery: Employ robust joinery techniques suitable for the design. Options include mortise and tenon, dovetails, pocket screws, or dowel joints. Ensure that joints are properly aligned and securely fastened with appropriate adhesives and fasteners. The structural integrity of the finished piece depends heavily on strong joinery.

Tip 4: Proper Surface Preparation: Prior to applying any finish, thoroughly sand all surfaces to achieve a smooth and even texture. Begin with coarser grit sandpaper and progressively move to finer grits. Proper surface preparation ensures optimal adhesion and a professional-looking finish.

Tip 5: Selection of Appropriate Finish: Choose a finish that complements the wood species and provides adequate protection. Options include varnish, lacquer, polyurethane, oil-based finishes, and water-based finishes. Consider factors such as durability, moisture resistance, and ease of application. Always apply finishes in a well-ventilated area.

Tip 6: Utilizing Clamps Effectively: Employ clamps liberally throughout the assembly process to ensure tight and accurate joints. Use protective pads between the clamps and the wood surface to prevent damage. Adequate clamping pressure is crucial for achieving strong and aesthetically pleasing bonds.

Tip 7: Prioritize Safety Measures: Always wear appropriate safety gear, including eye protection, hearing protection, and respiratory protection when operating power tools or working with finishes. Work in a well-ventilated area and follow manufacturer’s instructions for all tools and materials. Safety should be the paramount consideration throughout the project.

Adhering to these guidelines can significantly enhance the likelihood of a successful project, resulting in a functional and aesthetically pleasing addition to the living space. These considerations contribute to a durable and long-lasting piece of furniture.

The subsequent sections will delve into specific project examples and advanced woodworking techniques.

1. Design Aesthetics

Design aesthetics constitute a critical element within the domain of independent wooden surface construction, influencing not only the visual appeal of the finished product but also its overall functionality and integration within the intended living space. Careful consideration of aesthetic principles is essential for a successful outcome.

- Form and Proportion

The shape and relative dimensions of the surface significantly impact its visual harmony and usability. Rectangular, square, circular, and oval forms each offer distinct aesthetic qualities and functional attributes. Proportions must be carefully considered to ensure visual balance and compatibility with surrounding furniture and architectural elements. For example, a low, wide rectangular surface may complement a contemporary sectional sofa, while a taller, narrower circular surface might be better suited to a smaller, more traditional setting.

- Style and Theme

The chosen style should align with the overall design theme of the living space. Options range from minimalist modern, characterized by clean lines and simple forms, to rustic, emphasizing natural materials and textures. Other styles include traditional, industrial, and eclectic. Consistency in style creates a cohesive and visually pleasing environment. The selection of specific wood species, hardware, and finishes further reinforces the chosen style.

- Material and Texture

The choice of materials and their inherent textures contributes significantly to the aesthetic character. Different wood species exhibit distinct grains, colors, and textures. Reclaimed lumber, for example, offers a rustic and weathered appearance, while hardwoods such as walnut or cherry convey a sense of elegance and sophistication. Surface treatments, such as sanding, staining, and finishing, further enhance or modify the material’s texture.

- Color Palette

Color plays a vital role in establishing mood and creating visual interest. The color of the wood itself, as well as any applied stains or finishes, should complement the existing color palette of the living space. Consider the interplay of warm and cool tones, and the impact of contrasting or complementary colors. A well-chosen color palette can unify the space and enhance the overall aesthetic impact of the finished wooden surface.

These aesthetic facets are intertwined and should be considered holistically during the design process. A well-conceived design integrates form, style, material, and color to create a harmonious and functional addition to the living space, enhancing its visual appeal and overall usability. The integration of design aesthetics, therefore, elevates the final output from a mere piece of furniture to a statement of personal style and thoughtful craftsmanship.

2. Material Selection

Material selection constitutes a foundational element in the independent construction of wooden surfaces, directly influencing structural integrity, aesthetic qualities, and overall longevity. The chosen material dictates the feasibility of the project, the required woodworking techniques, and the final visual outcome. For instance, employing reclaimed lumber necessitates specific preparation methods to address existing imperfections, potentially influencing the chosen joinery and finishing strategies. Conversely, selecting a hardwood such as maple or walnut presents opportunities for refined detailing and sophisticated finishes, dictating a different set of tools and skill requirements. The causal relationship between material selection and the subsequent construction process is undeniable; inappropriate selection can lead to structural instability, premature failure, or aesthetic inconsistencies.

Consider the practical application of this understanding. A surface intended for heavy use, such as one frequently subjected to spills or heavy objects, demands a durable and water-resistant material. In such cases, hardwoods treated with a protective finish would be preferable to softer woods or materials prone to damage from moisture. Conversely, a surface primarily intended for decorative purposes might benefit from the aesthetic qualities of a less durable but visually striking material. The selection process should also account for factors such as budget constraints, availability of materials, and the individual’s skill level. A novice woodworker may find working with readily available and easily manipulated softwood more manageable than attempting to shape and join dense hardwood. Proper understanding of these nuances is critical for project success. Therefore, an understanding of the relative advantages and disadvantages of various materials, their properties, and how those properties relate to construction methods is the key to successful independent crafting.

In summary, material choice is not merely a preliminary step but rather an integral component that reverberates throughout the entire construction process. Challenges associated with material selection include accurately assessing material properties, sourcing sustainable options, and mitigating potential risks related to warping, cracking, or insect infestation. By recognizing and addressing these challenges, individuals can effectively harness the potential of various materials, resulting in a surface that is both aesthetically pleasing and structurally sound. This deliberate and informed approach ultimately elevates the finished product beyond mere functionality, transforming it into a testament of thoughtful craftsmanship.

3. Joinery Techniques

The selection and execution of appropriate joinery techniques are paramount to the structural integrity and aesthetic appeal of independently constructed wooden surfaces. The method employed dictates the long-term stability and durability of the finished piece, influencing its ability to withstand stress and maintain its intended form. Careful consideration of joinery is therefore integral to successful surface construction.

- Mortise and Tenon

The mortise and tenon joint, a time-honored method, involves fitting a projecting tenon into a corresponding mortise (or hole). This technique offers exceptional strength and resistance to racking forces, making it suitable for connecting legs to the surface or constructing sturdy frames. An example would be using mortise and tenon joints to connect the legs to the tabletop apron, providing a robust and visually appealing structure capable of supporting substantial weight.

- Dovetail Joints

Dovetail joints, characterized by interlocking wedge-shaped tails and pins, provide superior tensile strength and resistance to pulling forces. Often employed in drawer construction, dovetails can also be utilized to create visually striking corner joints on a wooden surface. A half-blind dovetail joint, for instance, might be used to connect the surface top to the side panels of a design incorporating storage, offering both strength and a concealed joint appearance.

- Pocket Hole Joinery

Pocket hole joinery involves drilling angled holes into one workpiece and then attaching it to another with screws. This method is relatively quick and easy, making it suitable for beginner woodworkers or for projects where speed is a priority. Pocket hole screws can be utilized to attach an apron to the underside of a wooden surface top, providing added support and preventing warping. However, the screws may be visible and require plugging or concealing for aesthetic purposes.

- Butt Joints with Reinforcement

Butt joints, where two pieces of wood are simply joined end to end or edge to edge, are the simplest form of joinery. However, they inherently lack strength and require reinforcement with fasteners, such as screws or nails, and adhesives. To improve the strength of a butt joint, consider using dowels, biscuits, or metal fasteners to provide additional mechanical support. Butt joints reinforced with screws and glue are often employed in hidden areas or for less critical structural elements.

These varied joinery methods offer different levels of strength, complexity, and aesthetic appeal. The selection of the appropriate technique depends on the design, the intended use, and the skill level of the individual. Careful consideration of these factors ensures that the finished wooden surface is not only visually appealing but also structurally sound and durable, capable of withstanding the rigors of everyday use. Skillful employment of joinery elevates the piece from a mere assembly of wooden components to a lasting testament to craftsmanship.

4. Finishing Methods

The application of appropriate finishing methods is critical in independent wooden surface construction, directly affecting the durability, aesthetic appeal, and longevity of the finished piece. The selected finish protects the wood from moisture, scratches, and UV damage, while simultaneously enhancing its natural beauty and highlighting its inherent characteristics. A well-executed finish transforms a raw wood surface into a durable and visually appealing furniture piece.

- Surface Preparation

Proper surface preparation is foundational to any successful finishing endeavor. This typically involves sanding the wood surface progressively with increasingly finer grits of sandpaper, creating a smooth and even substrate. Failing to adequately prepare the surface can result in uneven finish application, visible imperfections, and reduced adhesion. For instance, residual dust or sanding marks will become accentuated by the finish, compromising the final aesthetic. The process often includes cleaning the surface with a tack cloth to remove any remaining debris before applying the finish.

- Types of Finishes

A diverse range of finishes exists, each offering unique characteristics and benefits. Varnish provides a durable and water-resistant coating, suitable for high-traffic surfaces. Lacquer offers a fast-drying, hard finish, often used for its aesthetic appeal. Polyurethane offers exceptional durability and resistance to scratches and chemicals. Oil-based finishes penetrate the wood, enhancing its natural grain and color. Water-based finishes are low in VOCs and offer good durability. The choice of finish depends on the intended use of the wooden surface, the desired aesthetic, and environmental considerations.

- Application Techniques

The application technique significantly impacts the quality and appearance of the finish. Brushing, spraying, and wiping are common methods, each requiring specific skills and equipment. Brushing is suitable for smaller projects and allows for precise control. Spraying provides a smooth and even finish, but requires specialized equipment and ventilation. Wiping involves applying the finish with a cloth, allowing for controlled penetration and a natural look. Improper application can result in drips, runs, uneven coverage, and other imperfections that detract from the overall appearance.

- Protective Properties

The primary purpose of a finish is to protect the wood from environmental factors. Finishes provide resistance to moisture, preventing warping and cracking. They also protect against scratches and abrasions, maintaining the surface’s integrity. UV-resistant finishes prevent fading and discoloration caused by sunlight exposure. The level of protection required depends on the intended use and the environment in which the surface will be placed. Surfaces exposed to high moisture or heavy use require more durable and protective finishes.

In conclusion, the successful application of finishing methods is essential for transforming an independently constructed wooden surface into a functional and aesthetically pleasing furniture piece. From meticulous surface preparation to the selection of appropriate finishes and application techniques, each step contributes to the overall quality and longevity of the finished product. By carefully considering these factors, individuals can ensure that their creations are not only visually appealing but also capable of withstanding the test of time. This is critical for the overall project in independently creating wooden furniture.

5. Structural Integrity

Structural integrity is a fundamental consideration in the realm of independently constructing wooden surfaces, directly influencing the safety, stability, and longevity of the finished product. It encompasses the capacity of the surface to withstand applied loads and environmental stresses without experiencing deformation, failure, or significant degradation. Attaining adequate structural integrity requires a comprehensive understanding of material properties, joinery techniques, and design principles.

- Load-Bearing Capacity

Load-bearing capacity refers to the maximum weight or force that a structure can safely support. In the context of independently constructed wooden surfaces, accurately assessing the anticipated load is crucial. Overestimation of the load can lead to structural failure, while underestimation results in unnecessary material usage and increased cost. For example, if a surface is intended to support heavy objects such as books or appliances, a robust frame and sturdy legs are essential to prevent sagging or collapse. The selection of appropriate wood species, joinery methods, and support structures directly contributes to the surface’s ability to withstand the imposed load.

- Joint Strength and Stability

The strength and stability of joints play a critical role in maintaining structural integrity. Joints are the points where individual wooden components are connected, and their failure can compromise the entire structure. Various joinery techniques, such as mortise and tenon, dovetail, and screw-and-glue connections, offer different levels of strength and resistance to stress. The selection of an appropriate joinery method depends on the specific design, the type of wood used, and the anticipated load. Proper execution of the chosen joinery technique, including accurate cutting, fitting, and fastening, is essential for ensuring a stable and durable connection.

- Material Selection and Properties

The choice of materials directly impacts the overall structural integrity. Different wood species possess varying strength, stiffness, and resistance to decay. Hardwoods, such as oak and maple, are generally stronger and more durable than softwoods, such as pine and fir. However, softwoods may be more readily available and easier to work with, making them suitable for certain applications. Understanding the properties of different wood species and selecting the appropriate material for the intended purpose is critical. Additionally, factors such as moisture content and grain orientation can affect the wood’s strength and stability.

- Design and Geometry

The overall design and geometry significantly influence structural integrity. Certain shapes and configurations are inherently stronger than others. For example, a surface with a rectangular shape may require additional support structures to prevent sagging, while a circular surface may be more inherently stable. The placement and spacing of legs or other support members also affect the distribution of load and the overall stability. Careful consideration of design and geometry can optimize structural performance and minimize the risk of failure.

In summation, structural integrity is not a singular attribute but rather a composite of several interconnected factors. Load-bearing capacity, joint strength, material selection, and design geometry collectively contribute to the overall stability and durability of the surface. Understanding and addressing each of these facets is essential for independently constructing a wooden surface that is not only aesthetically pleasing but also safe, reliable, and long-lasting. Diligence in design and materials selection directly translates to furniture that stands the test of time, mitigating risks related to deformation and breakage.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions surrounding the independent construction of wooden surfaces. The information provided aims to clarify fundamental aspects of the process and to offer practical guidance based on established woodworking principles.

Question 1: What is the recommended wood type for a high-traffic surface?

For surfaces subjected to frequent use, hardwoods such as oak, maple, or walnut are preferable due to their inherent durability and resistance to wear. Softwoods, like pine or fir, are more susceptible to dents and scratches, rendering them less suitable for high-traffic applications.

Question 2: How can warping be prevented in a wooden surface?

Warping can be minimized through proper wood selection, acclimatization, and finishing techniques. Employing kiln-dried lumber with a low moisture content is essential. Allowing the wood to acclimatize to the environment in which it will be used reduces dimensional changes. Applying a consistent finish to all surfaces, including the underside, helps to balance moisture absorption and minimize warping tendencies.

Question 3: What is the best method for joining a tabletop to its legs?

Several methods exist, each offering varying degrees of strength and aesthetic appeal. Mortise and tenon joints provide exceptional strength and stability. Metal fasteners, such as threaded inserts and bolts, allow for easy disassembly. Pocket hole joinery offers a quick and relatively strong connection, albeit with less aesthetic refinement. The choice depends on the design and the desired level of structural integrity.

Question 4: What safety precautions should be observed during woodworking?

Safety is paramount. Eye protection, hearing protection, and respiratory protection are essential when operating power tools or working with finishes. A well-ventilated workspace is crucial to minimize exposure to dust and fumes. All tools should be used in accordance with manufacturer instructions. Clamps should be employed to secure workpieces, and caution exercised to prevent accidental injury.

Question 5: How can a smooth and durable finish be achieved?

Surface preparation is critical. Sanding the wood with progressively finer grits of sandpaper creates a smooth and even substrate. The choice of finish depends on the desired aesthetic and the intended use of the surface. Multiple thin coats of finish are generally preferable to a single thick coat, as they minimize the risk of drips and runs. Proper drying time between coats is essential for optimal adhesion and durability.

Question 6: Is reclaimed lumber suitable for surface construction?

Reclaimed lumber can add character and unique aesthetic qualities to a surface. However, it often requires careful preparation to address existing imperfections, such as nail holes, cracks, and uneven surfaces. Thorough cleaning, sanding, and repair are essential. Reclaimed lumber may also have a higher moisture content, necessitating proper acclimatization to prevent warping or cracking.

The principles and practices outlined in these responses provide a foundation for successful independent wooden surface construction. Adherence to these guidelines contributes to projects that are both aesthetically pleasing and structurally sound.

The subsequent section will present case studies demonstrating the application of these principles in real-world scenarios.

Conclusion

The preceding discussion explored the multifaceted nature of creating wooden surfaces independently. Key areas of focus included design aesthetics, material selection, joinery techniques, finishing methods, and structural integrity. Each aspect plays a crucial role in determining the final quality and longevity of the finished product. A thorough understanding of these elements is essential for individuals seeking to undertake such projects.

Mastering independent wooden surface construction presents both a challenge and an opportunity. The knowledge and skills acquired through this endeavor can be applied to a range of other woodworking projects, fostering a deeper appreciation for craftsmanship and design. Continued exploration and refinement of these techniques will undoubtedly yield rewarding results, contributing to both functional and aesthetically pleasing additions to any living space.