A self-constructed support structure, typically made from sheets of laminated wood, designed to hold a background for photography, videography, or event staging. It provides a portable and customizable alternative to commercially manufactured systems. These structures can range from simple A-frame designs to more elaborate constructions incorporating features like adjustable height and width.

The creation of these supports offers several advantages. It provides cost savings compared to purchasing pre-made stands. The user gains complete control over the dimensions and aesthetics, allowing for customization to specific needs and artistic preferences. Historically, the development of this solution is rooted in a desire for affordable and readily adaptable background support systems, especially within independent creative communities and smaller production teams.

The following discussion will delve into the construction techniques, material considerations, design variations, and safety precautions necessary for building a robust and effective background support from this material. Further sections will address finishing options and strategies for adapting the structure to diverse applications.

Construction Insights

The following guidelines aim to optimize the design and fabrication of a self-made background support utilizing laminated wood sheets, enhancing stability, portability, and longevity.

Tip 1: Material Selection: Prioritize high-grade plywood with minimal voids. Baltic birch plywood offers superior strength and stability compared to lower-cost alternatives, reducing the risk of warping and structural failure.

Tip 2: Design for Stability: Implement a wide base for enhanced equilibrium. A-frame designs should incorporate cross-bracing to prevent collapse. Consider the anticipated weight of the background material when determining base dimensions.

Tip 3: Precision Cutting: Employ accurate cutting techniques using a circular saw with a fine-tooth blade or a table saw to ensure clean edges and precise dimensions. Inaccurate cuts compromise structural integrity.

Tip 4: Secure Fastening: Utilize screws in conjunction with wood glue for robust joints. Counter-sink screw heads and fill with wood filler for a smooth, paintable surface. Avoid relying solely on nails or staples.

Tip 5: Reinforcement of Stress Points: Reinforce corners and joints with metal brackets or gussets, particularly in designs intended to support heavy backdrops or withstand frequent assembly and disassembly.

Tip 6: Portability Considerations: Design the structure for modular assembly and disassembly to facilitate transportation. Wing nuts or quick-release mechanisms can simplify the process.

Tip 7: Finishing for Protection: Apply a sealant or paint to protect the wood from moisture and wear. This extends the lifespan of the structure and enhances its aesthetic appeal. Exterior-grade finishes are recommended for outdoor use.

Adherence to these principles promotes the creation of a durable, reliable, and aesthetically pleasing background support. Thoughtful design and meticulous construction yield a valuable tool for various creative applications.

The subsequent section will explore aesthetic considerations and customization options for further tailoring the background support to specific requirements.

1. Material Grade

Material grade is a critical determinant of the structural integrity and long-term performance of a self-constructed background support. The selection of an appropriate material significantly influences its ability to withstand applied loads, resist warping or deformation, and maintain stability over time. Lower-grade plywood, characterized by inconsistencies in density, numerous voids, and weaker adhesive bonding, compromises the overall strength of the structure, potentially leading to premature failure, particularly when supporting heavy backdrops. Conversely, higher-grade plywood, such as Baltic birch or marine-grade options, provides increased resistance to bending and shear forces, ensuring a more robust and reliable support system.

For example, utilizing standard construction-grade plywood for a large, frequently used background support may result in sagging or bowing under the weight of the backdrop, necessitating costly repairs or replacement. In contrast, a support constructed from a higher-grade material is likely to maintain its structural integrity even under continuous heavy use, reducing the need for maintenance and extending its lifespan. Moreover, the surface quality of the plywood affects the ease with which it can be finished and painted, further contributing to the overall aesthetic appeal and professional appearance of the background support.

In summary, material grade exerts a direct and substantial impact on the performance and longevity of a self-made background support. Investing in a higher-quality material represents a prudent decision, mitigating the risk of structural failure, enhancing aesthetic appeal, and ensuring a reliable and long-lasting solution. The trade-off between initial cost and long-term value is essential to consider when selecting materials. The understanding of material properties directly informs the suitability of the final product.

2. Structural Stability

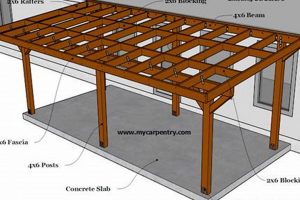

Structural stability is paramount in the design and construction of a background support from laminated wood sheets. The ability of the support to maintain its form and resist collapse under load directly influences its usability and safety. Inadequate stability can result in tipping, sagging, or complete failure, rendering the support unusable and potentially posing a hazard.

- Base Design and Footprint

The base design significantly affects stability. A wider base provides a lower center of gravity, increasing resistance to tipping. Triangular or A-frame configurations are inherently more stable than single vertical supports. The footprint, or surface area occupied by the base, directly correlates to stability; a larger footprint provides greater resistance to overturning forces. For example, a narrow A-frame support is more prone to tipping than one with widely splayed legs.

- Cross-Bracing and Reinforcement

Cross-bracing and reinforcement are essential for preventing racking or twisting of the structure. Diagonal braces connect opposing corners, distributing load and preventing deformation. Reinforcing joints with metal brackets or gussets strengthens connections and prevents separation under stress. Supports lacking adequate bracing are susceptible to instability, especially when subjected to uneven loads or external forces. A properly braced support maintains its shape and resists deformation, ensuring long-term stability.

- Material Thickness and Strength

The thickness and strength of the laminated wood sheets used directly impact the load-bearing capacity and stability of the support. Thicker materials offer greater resistance to bending and buckling. The choice of wood species and grade also affects strength; hardwoods generally provide greater stability than softwoods. Utilizing insufficiently strong materials can result in sagging or failure under load. Properly selecting appropriately sized and graded materials ensures sufficient strength to support the intended backdrop without compromising stability.

- Joint Construction and Fasteners

The method of joining the various components is critical for maintaining structural integrity. Secure joints prevent movement and distribute load effectively. The use of screws in conjunction with adhesive is preferable to nails or staples, providing a stronger and more durable connection. Proper alignment and accurate fitting of joints are essential for preventing stress concentrations and ensuring uniform load distribution. Poorly constructed joints compromise stability and can lead to premature failure. Utilizing robust joinery techniques ensures a rigid and stable structure capable of withstanding repeated use.

These facets demonstrate that structural stability is not a singular property but rather a culmination of design choices, material selections, and construction techniques. A well-designed and carefully constructed background support, incorporating these principles, provides a safe, reliable, and long-lasting solution for various creative applications. The interaction of each component directly influences the success of the overall system.

3. Joint Integrity

Joint integrity, the strength and durability of connections within a self-constructed background support, is a fundamental aspect determining its overall reliability and longevity. The stability and load-bearing capacity of the entire structure are directly dependent on the quality of its joints. Compromised joint integrity can lead to instability, sagging, or even complete structural failure, rendering the support unusable and potentially hazardous.

- Adhesive Selection and Application

The type of adhesive employed and the method of its application significantly impact joint strength. Wood glue, specifically formulated for woodworking, provides a robust bond between plywood surfaces. Proper surface preparation, including cleaning and sanding, is essential for optimal adhesion. Insufficient glue application or the use of an inappropriate adhesive results in a weak bond, prone to separation under stress. Example: Using construction adhesive instead of wood glue will decrease the structural reliability and make the diy plywood backdrop stand not long lasting.

- Fastener Type and Placement

The selection and placement of fasteners, such as screws or bolts, contribute significantly to joint integrity. Screws, offering superior holding power compared to nails, are generally preferred for critical joints. Proper screw length and diameter are essential for ensuring adequate penetration and grip. Pre-drilling pilot holes prevents splitting of the plywood, maximizing fastener effectiveness. The strategic placement of fasteners, avoiding excessive proximity to edges or corners, minimizes the risk of material failure. Example: using nail at the joint for the stand will lead to failure in long term and not recommended.

- Joint Design and Construction Techniques

The design of the joints themselves influences their inherent strength and stability. Mitered joints, while aesthetically pleasing, offer less surface area for bonding compared to butt joints or lap joints. Reinforcing joints with gussets or brackets enhances their resistance to shear forces and twisting. Accurate cutting and fitting of components are crucial for ensuring tight, flush joints. Sloppy or imprecise joinery compromises the overall structural integrity of the support. Example: mitered joint can be more decorative and should be combined with fastener or other reinforcement to increase the load bearing capacity.

- Environmental Factors and Maintenance

Environmental factors, such as moisture and temperature fluctuations, can degrade joint integrity over time. Exposure to excessive moisture can weaken adhesive bonds and promote wood rot. Regular inspection and maintenance are essential for identifying and addressing potential joint failures. Tightening loose fasteners and reapplying adhesive as needed can prolong the lifespan of the support. Protecting the support from extreme environmental conditions minimizes the risk of degradation. Example: Keeping the diy plywood backdrop stand in a dry environtment will prevent joint damage.

In summary, joint integrity is a multifaceted aspect that relies on the careful selection of materials, meticulous construction techniques, and ongoing maintenance. A well-executed background support, incorporating robust joints, provides a stable, reliable, and long-lasting platform for various photographic and videographic applications. The interplay between these different elements dictates the longevity and usability of the self-constructed support structure.

4. Surface Finish

Surface finish, in the context of a self-constructed background support, extends beyond mere aesthetics; it is a crucial element affecting both the durability and usability of the structure. The application of a suitable finish to the plywood surface acts as a protective barrier against environmental factors such as moisture, ultraviolet radiation, and physical abrasion. An unfinished surface is susceptible to water absorption, leading to warping, swelling, and ultimately, structural degradation. Furthermore, a rough or uneven surface can snag or damage delicate backdrop materials, reducing the overall professionalism and functionality of the stand.

A properly applied surface finish can significantly extend the lifespan of the background support. For instance, a coat of polyurethane varnish provides a durable, water-resistant layer, preventing moisture penetration and protecting the underlying wood from decay. Applying paint offers not only aesthetic customization but also a protective shield against UV radiation, preventing discoloration and weakening of the plywood over time. The choice of finish should be tailored to the intended use of the support; exterior-grade finishes are recommended for structures frequently used outdoors, while interior-grade finishes may suffice for primarily indoor applications. The selection and application process should also consider the potential for off-gassing, especially in enclosed studio environments. This ensures that the material isn’t affecting the background when it is used.

In conclusion, the surface finish is an indispensable component of a self-made background support. It safeguards the structural integrity of the plywood, enhances its resistance to environmental damage, and contributes to the overall aesthetic appeal and professional presentation of the backdrop system. Neglecting this aspect can result in premature failure, increased maintenance costs, and compromised usability. The added time and cost of surface finishing are easily justified by the extended lifespan and improved performance of the completed structure. The surface finish dictates the final experience.

5. Transportability

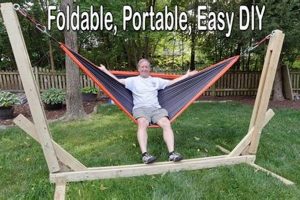

Transportability is a critical consideration in the design and construction of a self-made background support, especially when the intended use case involves location shoots or events outside of a permanent studio setting. The inherent size and weight of plywood, the primary material, present challenges to easy transport. A monolithic, non-collapsible structure becomes logistically difficult to move, requiring a larger vehicle and potentially multiple individuals. The lack of transportability limits the versatility and practicality of the support, restricting its use to fixed locations. For example, a photographer specializing in outdoor portraiture requires a readily transportable support to accommodate varying locations and environmental conditions.

Addressing transportability typically involves designing the support for modular assembly and disassembly. This approach breaks down the structure into smaller, more manageable components that can be easily packed and carried. Employing quick-release mechanisms, such as wing nuts or cam levers, facilitates rapid assembly and disassembly without the need for specialized tools. Furthermore, considering the dimensions of standard vehicle cargo areas during the design phase ensures that the disassembled components can be transported efficiently. A support designed for easy transport expands its potential applications, allowing it to be used in diverse environments and settings. An example is a backdrop stand being used for different events.

Ultimately, the integration of transportability considerations into the design process transforms a potentially unwieldy structure into a versatile and adaptable tool. This enhances the practical value of the DIY project, maximizing its usefulness across a wider range of photographic, videographic, and event-related applications. The careful consideration of weight distribution, component size, and assembly mechanisms ensures that the background support can be readily moved and deployed as needed, making it a valuable asset for any creative professional or enthusiast. The goal of the DIY project should be the practical application in mind.

Frequently Asked Questions

The following addresses common inquiries regarding the construction, usage, and maintenance of self-made background supports utilizing laminated wood sheets.

Question 1: What is the optimal thickness for plywood used in the construction of a backdrop support?

The optimal thickness depends on the intended load and overall dimensions. For smaller supports and lighter backdrops, inch plywood may suffice. However, for larger supports or heavier backdrops, inch plywood is recommended to ensure adequate structural integrity and prevent sagging.

Question 2: How can warping of the plywood be prevented?

Preventing warping involves several measures. Utilizing high-grade plywood with minimal voids is crucial. Sealing the plywood with a water-resistant finish minimizes moisture absorption, a primary cause of warping. Storing the support in a dry environment and avoiding direct sunlight also helps to prevent warping.

Question 3: What types of fasteners are most suitable for joining plywood components?

Screws, in conjunction with wood glue, provide the most robust and durable connections. Avoid relying solely on nails or staples, as they offer insufficient holding power. Counter-sinking screw heads and filling with wood filler creates a smooth, paintable surface.

Question 4: How can the stability of the backdrop support be enhanced, particularly for outdoor use?

Stability can be enhanced by increasing the width of the base, employing cross-bracing, and adding weight to the base. Metal feet or rubber pads can also improve stability on uneven surfaces. For outdoor use, consider anchoring the support to the ground using stakes or sandbags.

Question 5: What type of finish is recommended for protecting the plywood from environmental damage?

For indoor use, a polyurethane varnish or paint provides adequate protection. For outdoor use, an exterior-grade sealant or paint specifically formulated for marine applications is recommended. These finishes offer superior resistance to moisture, UV radiation, and temperature fluctuations.

Question 6: How can the backdrop support be adapted for different backdrop sizes and materials?

Adaptability can be achieved through adjustable height and width mechanisms. Telescoping poles or sliding crossbars allow for accommodating various backdrop sizes. Consider using clamps or clips to secure different types of backdrop materials, such as fabric, paper, or vinyl.

These answers provide a foundational understanding of key considerations for building and maintaining a plywood backdrop support. Proper planning and execution are essential for ensuring a safe, reliable, and versatile structure.

The next section will delve into specific design variations and advanced construction techniques for those seeking to further customize their background support.

Conclusion

The preceding discourse has comprehensively explored the various facets of “diy plywood backdrop stand” construction, emphasizing the importance of material selection, structural stability, joint integrity, surface finishing, and transportability. Each element contributes significantly to the overall functionality and longevity of the support system. Sound construction practices and adherence to safety guidelines are paramount in creating a reliable and adaptable structure for diverse creative applications.

Successful implementation of the described techniques yields a cost-effective and customizable solution for background support needs. Further exploration of advanced design principles and specialized materials may lead to even more innovative and robust constructions. The potential for improvement and adaptation remains substantial, encouraging continued experimentation and refinement within the DIY community.