A structure created by individuals for the purpose of supporting a bicycle during maintenance and servicing tasks characterizes a self-constructed bicycle maintenance fixture. This device allows for easier access to various components of the bicycle, facilitating repairs, adjustments, and cleaning. An example would be a frame built from repurposed plumbing pipes and fittings to hold a bike securely off the ground.

The ability to fabricate a personal support system for bicycle upkeep provides several advantages, including cost savings compared to purchasing commercially available options. Furthermore, constructing such a device offers customization opportunities, allowing for tailoring to specific bicycle types and individual ergonomic preferences. Historically, these home-built solutions reflect an ingenuity born from necessity, predating the widespread availability of specialized cycling tools and equipment.

The subsequent sections will explore various designs, materials, and construction techniques for erecting these customized bicycle maintenance platforms, offering practical guidance and considerations for those seeking to create their own.

Essential Construction Considerations

The creation of a stable and functional support device for bicycle maintenance requires careful planning and execution. The following guidance will assist in the development of a suitable apparatus.

Tip 1: Prioritize Stability: The foundation must ensure lateral and vertical stability. A wide base or a weighted platform helps prevent tipping during repair procedures. Examples include using a tripod design or attaching a heavy counterweight.

Tip 2: Secure Clamping Mechanism: The clamping system should firmly hold the bicycle frame without causing damage. Consider using padded clamps or adjustable straps to distribute pressure evenly and prevent scratching the frame’s finish.

Tip 3: Adjustable Height: Incorporate a mechanism for adjusting the height of the bicycle. This allows for comfortable working positions, minimizing strain on the back and neck during prolonged repair sessions. Telescoping tubes or ratcheting systems are suitable options.

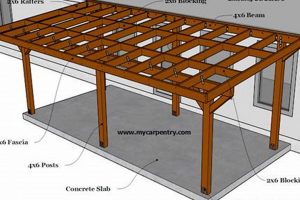

Tip 4: Material Selection: Choose materials that are durable and resistant to corrosion. Steel, aluminum, or sturdy wood can be used, depending on budget and skill level. Ensure that all materials are properly joined and reinforced to withstand the weight of a bicycle.

Tip 5: Frame Compatibility: The design should accommodate a range of bicycle frame sizes and geometries. Adjustable clamps and a versatile mounting system will increase the device’s utility.

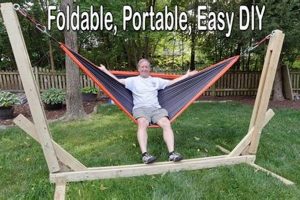

Tip 6: Consider Portability: If space is limited, design the device to be collapsible or easily disassembled for storage. This allows for efficient use of space when the repair stand is not in use.

Tip 7: Cable Management: Integrate a system for managing cables and housing during repairs. This prevents tangling and keeps the workspace organized. Hooks or clips can be attached to the stand to hold cables in place.

By considering these factors, individuals can fabricate a device that provides a safe, effective, and personalized platform for bicycle maintenance. The construction of a suitable bicycle support frame contributes to a more efficient and enjoyable repair experience.

The concluding section will summarize the key aspects of creating a personalized bicycle support system, highlighting the benefits of this endeavor.

1. Stability

Stability represents a critical attribute of a self-constructed bicycle maintenance fixture, directly influencing the safety and efficiency of repair operations. Adequate stability minimizes the risk of the bicycle tipping or shifting during service procedures, which could lead to damage to the bicycle or injury to the user. The following facets explore the specific elements that contribute to overall stability.

- Base Design and Footprint

The base of a self-constructed bicycle maintenance structure serves as its foundation. A wider footprint generally provides greater stability. A tripod design, for example, offers inherent stability due to its three points of contact with the ground. Conversely, a narrow or uneven base can compromise stability, particularly when working on heavier bicycles or applying significant force during repairs.

- Material Weight and Distribution

The weight of the materials used in the construction, and how that weight is distributed, affects the overall stability. A heavier base or strategically placed counterweights can lower the center of gravity, making the stand less prone to tipping. Conversely, a lightweight stand may be more portable but less stable, especially when supporting heavier bicycles.

- Clamping Mechanism Security

The design of the clamping mechanism has stability implications. A secure clamp that firmly grips the bicycle frame is essential to prevent movement during repairs. Slippage or inadequate clamping force can introduce instability, increasing the risk of the bicycle shifting or falling. Examples include incorporating adjustable clamps or padded grips to ensure a secure hold without damaging the frame.

- Surface Conditions and Adjustments

The stability is also influenced by the surface on which the stand is placed. Uneven or slippery surfaces can compromise the stand’s stability, even with a well-designed base. Adjustable feet or leveling mechanisms can compensate for uneven surfaces, ensuring a stable platform for repairs. Failure to account for surface conditions can lead to instability, increasing the risk of accidents.

These facets of stability are interdependent and contribute to the overall effectiveness of the self-constructed bicycle support. Prioritizing these elements during the design and construction phases is essential for creating a safe and reliable tool for bicycle maintenance. Ensuring structural integrity is of utmost importance for self-built projects.

2. Frame Protection

The safeguarding of the bicycle frame from damage during maintenance procedures constitutes a critical design consideration when constructing a self-made bicycle repair fixture. Direct contact between the fixture and the frame introduces the potential for scratches, dents, or even structural compromise, particularly with lightweight or carbon fiber frames. The effectiveness of a self-built bicycle support system hinges on its ability to secure the bicycle without imparting any harm to its structural integrity or finish. The absence of adequate frame protection negates the benefits of convenient bicycle access and elevated work positioning.

Implementation of protective measures manifests in various design elements. Padded clamping surfaces, often constructed from materials such as rubber, neoprene, or specialized foam, create a buffer between the metal or plastic components of the fixture and the bicycle frame. Adjustable clamping pressure regulates the force applied, preventing over-tightening that can lead to deformation or cracking of thin-walled tubes. Some designs incorporate a cradle system, where the bicycle rests on padded supports instead of being clamped directly, distributing the weight evenly and minimizing stress points. For instance, a stand designed for vintage bicycles with delicate paint finishes would necessitate particularly gentle clamping mechanisms.

Failure to prioritize frame protection results in preventable damage, diminishing the aesthetic and functional value of the bicycle. Selecting appropriate materials, designing a secure yet non-marring clamping system, and implementing protective padding are essential steps in creating a practical and effective bicycle maintenance fixture. Frame protection is not merely an aesthetic consideration; it ensures the longevity and performance of the bicycle. Therefore, meticulous attention to this aspect is paramount when constructing a bicycle repair solution.

3. Adjustability

The capacity for adjustment within a self-constructed bicycle maintenance fixture directly influences its versatility and suitability for various bicycle types and user preferences. A fixed configuration inherently limits the range of bicycles that can be accommodated and may compromise the user’s ergonomic comfort during maintenance tasks. Therefore, incorporating adjustable elements is crucial for maximizing the functionality and usability of the structure.

- Height Adjustment

Vertical adjustability allows for optimizing the working height of the bicycle. Different users have varying heights, and different repair tasks benefit from different working angles. A height-adjustable mechanism, implemented through telescoping tubes or a ratcheting system, enables the user to position the bicycle at an ergonomically suitable level, reducing strain and improving accessibility to components. A lack of height adjustment may result in back pain or difficulty reaching certain areas of the bicycle.

- Clamp Angle Adjustment

The ability to adjust the angle of the clamping mechanism expands the fixture’s compatibility with diverse frame geometries. Bicycles with sloping top tubes or unconventional frame shapes require a clamp that can be angled to provide a secure and balanced hold. A fixed-angle clamp may not be suitable for all bicycles, leading to instability or damage. An adjustable clamp angle ensures secure support across a wider range of bicycle designs.

- Clamp Size Adjustment

The diameter and shape of the clamping jaws should be adjustable to accommodate different frame tube sizes. Bicycle frames utilize tubes with varying diameters and cross-sections. A clamp that is too large or too small may not provide a secure grip, leading to slippage or damage to the frame. Adjustable clamping jaws, often achieved through interchangeable inserts or adjustable bolts, allow for a customized fit for various frame tubes.

- Horizontal Position Adjustment

Horizontal adjustment, allowing the bicycle to be shifted forward or backward relative to the base, offers increased accessibility to specific bicycle components. This functionality is particularly useful when working on areas near the front or rear of the bicycle. A fixed horizontal position may limit access and require the user to contort their body to reach certain components. A sliding or telescoping arm enables precise positioning for optimal access.

The integration of these adjustable features transforms a basic self-constructed bicycle support into a versatile and user-friendly tool. By accommodating diverse bicycle types and user preferences, a highly adjustable fixture provides a significant advantage over a rigid, non-adjustable design. The enhanced functionality and ergonomic benefits contribute to a more efficient and comfortable bicycle maintenance experience.

4. Material Durability

The longevity and reliability of a self-constructed bicycle maintenance fixture are intrinsically linked to the durability of the materials employed in its construction. Material durability dictates the ability of the structure to withstand the stresses of supporting a bicycle during repairs, resisting wear and tear, and maintaining structural integrity over an extended period. Selection of appropriate materials is thus paramount for creating a functional and safe repair stand.

- Resistance to Static Load

A primary function of a bicycle repair stand is to support the static weight of a bicycle. Materials must exhibit sufficient tensile strength and compressive strength to prevent deformation or failure under load. For example, using thin-walled PVC pipe as a primary structural component would likely result in collapse under the weight of a bicycle, whereas steel or thick-walled aluminum would provide adequate support. The material’s ability to resist static load directly influences the safety and longevity of the stand.

- Corrosion Resistance

Exposure to environmental factors, such as moisture and humidity, can lead to corrosion in certain materials. Rust on steel components can weaken the structure and compromise its stability. Aluminum, while generally corrosion-resistant, can still be susceptible to galvanic corrosion when in contact with dissimilar metals. Utilizing corrosion-resistant materials, such as stainless steel or powder-coated steel, or implementing protective coatings can mitigate this risk, extending the lifespan of the repair stand.

- Resistance to Fatigue

Repeated stress cycles, such as the clamping and unclamping of bicycles, can induce fatigue in structural materials. Over time, fatigue can lead to cracks and eventual failure. Materials with high fatigue strength, such as certain grades of steel or reinforced polymers, are better suited for components that experience cyclic loading. Understanding the fatigue properties of the materials used is essential for ensuring the long-term reliability of the repair stand.

- Impact Resistance

Accidental impacts or collisions can occur during bicycle maintenance, potentially damaging the repair stand. Materials with high impact resistance, such as hardened steel or impact-resistant plastics, are less likely to fracture or deform under such circumstances. Selecting materials that can withstand accidental impacts helps to maintain the structural integrity of the stand and prevent potential hazards.

In summary, the durability of the materials selected for a self-constructed bicycle support system directly correlates with its performance, safety, and longevity. Careful consideration of material properties, including resistance to static load, corrosion, fatigue, and impact, is crucial for creating a reliable and durable tool for bicycle maintenance. Substituting inferior materials to save cost may result in a hazardous work environment and the need for frequent repairs or replacement.

5. Portability

The characteristic of portability significantly enhances the utility of a self-constructed bicycle maintenance fixture, particularly for individuals with limited storage space or those who require the ability to transport the stand for off-site repairs and adjustments. The design and material choices fundamentally influence the ease with which the apparatus can be moved and stored.

- Collapsible Design

A design that allows the stand to be folded or disassembled into smaller components is essential for maximizing portability. Hinged joints, telescoping sections, or detachable legs enable compact storage and transportation. For example, a stand with legs that fold flat against the main support structure occupies significantly less space than a fixed-leg design. The ease of collapsing and reassembling the stand directly impacts its convenience for mobile use.

- Material Weight

The weight of the materials used in construction directly influences the ease of carrying the stand. Lighter materials, such as aluminum or lightweight steel tubing, reduce the overall weight of the apparatus, making it more manageable for transportation. Conversely, heavier materials, while potentially offering greater stability, can compromise portability. A balance must be struck between stability and weight to achieve optimal functionality.

- Integrated Handles and Carrying Cases

The incorporation of integrated handles or the provision of a carrying case further enhances portability. Handles provide a convenient grip for lifting and transporting the stand, while a carrying case protects the components from damage during transport and facilitates organization. These features are particularly beneficial for frequent transport or for protecting the stand from the elements during storage.

- Size and Form Factor When Stored

The dimensions and shape of the stand when collapsed or disassembled determine how easily it can be stored in a vehicle or storage area. A compact and easily stackable form factor is desirable for maximizing storage efficiency. Bulky or irregularly shaped components can be difficult to pack and store, reducing the overall convenience of the portable design.

These facets of portability are crucial considerations in the design and construction of a self-made bicycle repair fixture. Prioritizing these elements enhances the versatility of the apparatus, making it suitable for a wider range of users and applications. Compromises made in the pursuit of portability may necessitate trade-offs in other areas, such as stability or weight capacity, requiring careful evaluation during the design process.

6. Clamp Security

Clamp security represents a fundamental attribute of any self-constructed bicycle maintenance fixture. The clamping mechanism directly interfaces with the bicycle frame, and its effectiveness in securely holding the bicycle is paramount for safe and efficient repairs. A compromised clamping system introduces the risk of the bicycle slipping, falling, or sustaining damage, rendering the stand unusable and potentially hazardous.

- Clamping Force Distribution

The distribution of clamping force across the frame tubes is critical for preventing localized stress and potential damage. Clamping mechanisms should distribute force evenly over a wide area to avoid crushing or deforming the frame. Examples include using padded clamping jaws made from materials like rubber or neoprene to cushion the frame and distribute pressure. Failure to distribute force evenly can result in dents or cracks, particularly on thin-walled or carbon fiber frames.

- Clamp Material Compatibility

The materials used in the clamp construction must be compatible with the bicycle frame material. Dissimilar metals in contact can lead to galvanic corrosion, weakening the frame over time. Similarly, abrasive materials can scratch or wear away the frame’s finish. Using compatible materials, such as plastic or rubber-coated clamps, minimizes the risk of damage. For instance, a steel clamp used directly on a carbon fiber frame can cause significant damage due to differing material properties.

- Locking Mechanism Reliability

The locking mechanism that secures the clamp in place must be reliable and resistant to loosening during repairs. A secure locking mechanism prevents the clamp from inadvertently releasing, which could cause the bicycle to fall. Examples include using ratcheting mechanisms, cam levers, or threaded fasteners with locking nuts to ensure a firm hold. A weak or unreliable locking mechanism introduces a significant safety hazard.

- Adjustability and Adaptability

The clamping mechanism should be adjustable to accommodate different frame tube diameters and shapes. Bicycle frames come in a variety of sizes and geometries, and a versatile clamp is essential for ensuring a secure fit. Adjustable clamping jaws, interchangeable inserts, or articulating arms allow the stand to adapt to different frame configurations. A non-adjustable clamp may not be suitable for all bicycles, limiting the stand’s utility.

These facets of clamp security underscore the importance of careful design and construction when creating a do-it-yourself bicycle repair fixture. Neglecting clamp security can compromise the safety and functionality of the stand, potentially leading to damage to the bicycle or injury to the user. Prioritizing these considerations ensures a reliable and effective tool for bicycle maintenance.

Frequently Asked Questions

The following questions address common inquiries and concerns regarding the construction and utilization of self-made bicycle maintenance fixtures. The information provided aims to offer clarity and guidance on this subject matter.

Question 1: What are the primary advantages of constructing a bicycle repair stand as opposed to purchasing a commercially manufactured unit?

The construction of a bicycle repair stand typically yields cost savings, customization possibilities, and the satisfaction of a self-executed project. Commercially manufactured stands may offer more refined features or greater portability, but often at a higher price point.

Question 2: What materials are most suitable for constructing a stable and durable bicycle repair stand?

Steel, aluminum, and robust hardwoods are commonly used materials. Steel offers high strength and weldability but is susceptible to corrosion. Aluminum is lightweight and corrosion-resistant but generally requires specialized welding techniques. Hardwoods provide a readily available and aesthetically pleasing option, but may lack the strength and durability of metals.

Question 3: How can the risk of damaging the bicycle frame be minimized when using a self-made repair stand?

Employing padded clamping surfaces made of rubber, neoprene, or similar materials is crucial. Furthermore, regulating the clamping force and ensuring compatibility between the clamp material and the frame material minimizes the likelihood of scratches, dents, or corrosion.

Question 4: What design features contribute to the stability of a bicycle repair stand?

A wide base, a low center of gravity, and a secure clamping mechanism are primary factors. A tripod base or a weighted platform enhances stability, while a clamp that firmly grips the frame prevents unwanted movement during repairs.

Question 5: How can a self-made bicycle repair stand be made adjustable to accommodate different bicycle types and user heights?

Incorporating telescoping tubes, ratcheting mechanisms, or adjustable clamping arms allows for customization of the stand’s height, clamp angle, and clamp size. These features ensure compatibility with various frame geometries and ergonomic preferences.

Question 6: What safety precautions should be observed when constructing and using a bicycle repair stand?

Wearing appropriate safety gear, such as eye protection and gloves, is essential. Ensuring that all connections are secure and that the stand is placed on a level surface is also critical. Regular inspection of the stand for signs of wear or damage helps to prevent accidents.

In summary, the creation of a functional and safe self-made bicycle support device necessitates careful consideration of material selection, design principles, and safety protocols. Proper execution of these elements results in a valuable tool for bicycle maintenance.

The subsequent segment will provide a summarized overview of the key considerations involved in designing a DIY bicycle repair stand.

DIY Bicycle Repair Stand

The preceding discussion has explored the multifaceted considerations inherent in the construction of a “diy bicycle repair stand”. Key aspects highlighted include stability, frame protection, adjustability, material durability, clamp security, and portability. Each element plays a crucial role in determining the overall functionality, safety, and longevity of the device. The informed application of these principles allows for the creation of a practical and economical alternative to commercially available options.

The decision to fabricate a “diy bicycle repair stand” requires careful assessment of individual needs, available resources, and technical capabilities. While offering potential cost savings and customization opportunities, such a project demands a commitment to sound engineering practices and adherence to safety guidelines. A well-executed “diy bicycle repair stand” can significantly enhance the efficiency and convenience of bicycle maintenance, contributing to the longevity and performance of the bicycle itself. The ongoing evaluation and refinement of design and construction techniques will further advance the field of self-fabricated bicycle maintenance equipment.