The practice of constructing personal devices for supporting targets during shooting activities embodies a resourceful approach to recreational shooting and marksmanship training. Individuals undertake these projects to create customized and often cost-effective solutions for target placement and stability. These structures range from simple wooden frames to more elaborate designs incorporating metal or repurposed materials.

Creating target supports provides tangible advantages, including cost reduction, tailoring designs to specific shooting disciplines or environments, and fostering self-sufficiency in shooting-related activities. Historically, marksmen and hunters have often relied on their ingenuity to craft necessary equipment. This reflects a tradition of self-reliance and adaptation that continues to influence the modern shooting sports landscape. The ability to construct durable and adaptable target holders enhances the overall shooting experience and promotes responsible firearms handling.

Considerations when planning a target support project include the type of target to be used (paper, steel, reactive), the expected shooting distances, and the prevailing weather conditions. Selecting appropriate materials and construction techniques will determine the overall durability and stability of the finished product. Furthermore, safety remains paramount throughout the design and usage phases, ensuring that the constructed support functions reliably and poses no hazard to the shooter or bystanders.

Essential Considerations for Target Support Construction

Prudent planning and execution are critical when undertaking the creation of personal target support structures. Adherence to safety protocols and careful material selection are paramount for ensuring both the effectiveness and longevity of the finished product.

Tip 1: Prioritize Stability: A stable base is fundamental. Broad footings or a weighted bottom significantly reduce the risk of tipping, particularly in windy conditions or when using larger targets.

Tip 2: Choose Durable Materials: Consider weather resistance and impact resistance when selecting materials. Pressure-treated lumber, steel, or durable composite materials offer greater longevity compared to untreated wood.

Tip 3: Design for Target Compatibility: Ensure the structure is adaptable to the specific type of target being used. This may involve incorporating clips, frames, or adjustable mounting points for accommodating various target sizes and styles.

Tip 4: Emphasize Safety Features: Avoid sharp edges or protruding hardware that could pose a safety hazard. Incorporate highly visible markings to clearly delineate the target area.

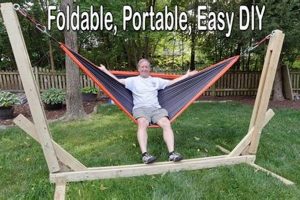

Tip 5: Ensure Portability (If Required): If frequent relocation is anticipated, consider a lightweight, foldable design. Detachable legs or a breakdown frame can significantly ease transportation.

Tip 6: Consider Backstop Integration: Depending on the shooting environment, integrating a backstop element can enhance safety by containing errant shots or ricochets. Fabric or rubber sheeting can be effective backstop materials.

Tip 7: Protect Against the Elements: For permanent installations, apply a weather-resistant coating or sealant to protect the structure from moisture and UV damage. Regular maintenance will extend the lifespan of the support.

Diligence in these areas ensures that the constructed target support not only functions effectively but also contributes to a safe and enjoyable shooting experience. A well-designed and constructed target support is a worthwhile investment for any shooting enthusiast.

The next section will address specific design options and potential challenges encountered during construction.

1. Material Selection

The selection of materials is a critical determinant of the functionality, longevity, and safety of structures supporting targets. The materials chosen directly influence the structure’s ability to withstand the impact of projectiles, resist environmental degradation, and maintain stability during use. Failure to adequately consider material properties can lead to premature failure, increased risk of ricochet, or structural instability, all of which compromise safety and the overall effectiveness of the design.

For example, untreated wood, while initially cost-effective, is susceptible to rot, insect infestation, and splitting, rendering it unsuitable for long-term outdoor use. In contrast, pressure-treated lumber offers enhanced resistance to these factors, extending the lifespan of the structure. Similarly, metal components, such as steel tubing, provide superior strength and rigidity, but require appropriate coatings to prevent corrosion. Repurposed materials, such as discarded pallets or tires, can offer cost-effective solutions, but must be carefully inspected for pre-existing damage or structural weaknesses before incorporation into the design.

Therefore, informed material selection, based on a clear understanding of material properties and environmental conditions, is essential for ensuring the success of projects. It balances cost considerations with the need for durability, safety, and long-term performance. Incorrect material choices can negate design efforts and lead to costly replacements or hazardous shooting conditions. Proper material consideration is key to a functional target support.

2. Structural Integrity

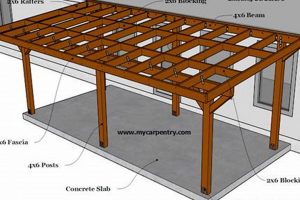

Structural integrity, in the context of constructing devices for supporting targets, directly relates to the capacity of the assembled unit to withstand imposed loads and environmental stressors without deformation or failure. The design and construction methods employed directly determine the ability of a target support to maintain its intended configuration under use, thereby influencing the accuracy and safety of shooting activities.

- Load-Bearing Capacity

The ability to bear weight, specifically the target itself, and potentially additional loads such as wind or accidental impact, dictates the minimum acceptable strength of the support. Overestimation of the expected loads results in unnecessary material use and increased cost. Underestimation leads to instability and potential collapse. Real-world examples include the use of thicker gauge steel tubing in frames designed to hold heavier steel targets, and the reinforcement of wooden frames with cross-bracing to prevent sagging.

- Joint Strength and Stability

Connections between individual components represent critical points of potential failure. The chosen method of joining materials, whether welding, bolting, or adhesive bonding, must be appropriate for the materials being joined and the anticipated stresses. Improperly welded joints or loose fasteners compromise the structural integrity of the entire system. The use of gussets or reinforcing plates at joints increases load distribution and enhances stability.

- Material Resilience to Impact

While target supports are not intended to be directly impacted by projectiles, stray shots or ricochets can occur. The ability of the material to absorb impact energy without shattering or fracturing is an important safety consideration. Brittle materials like thin-walled PVC pipe are prone to catastrophic failure upon impact, while more resilient materials like steel or dense hardwoods offer greater resistance. The incorporation of a sacrificial element, such as a sheet of rubber or heavy fabric, can further mitigate the risk of ricochet.

- Resistance to Environmental Factors

Outdoor target supports are exposed to a range of environmental stressors, including moisture, temperature fluctuations, and ultraviolet radiation. These factors can degrade materials over time, weakening the structure and compromising its integrity. Using weather-resistant materials, such as pressure-treated lumber or powder-coated steel, and applying protective coatings can significantly extend the lifespan of the support. Regular inspection and maintenance are essential for identifying and addressing potential problems before they lead to structural failure.

These elements collectively contribute to a robust target support. A design that adequately addresses each consideration leads to a durable, reliable, and safe platform for shooting activities, minimizing the risk of structural failure and enhancing the overall shooting experience. Conversely, neglecting structural integrity jeopardizes safety and negates the benefits of the project.

3. Target Compatibility

Target compatibility in construction of personal target supports is a critical determinant of their practicality and effectiveness. The design must align with the intended target type paper, steel, reactive to ensure proper mounting, stability, and optimal visibility. A support designed exclusively for paper targets, for instance, lacks the structural integrity to withstand the impact of steel targets, potentially leading to damage or collapse. Conversely, an over-engineered support for steel targets may prove unnecessarily cumbersome and expensive for simple paper target practice. The connection is a direct cause-and-effect: inappropriate design leads to functional failure, whereas careful matching improves performance.

Real-world examples highlight this interplay. A simple A-frame stand constructed from wood effectively holds paper targets using clips or stapled cardboard. However, implementing this for steel targets requires substantial reinforcement or redesign with robust hanging mechanisms. Reactive targets, such as exploding targets or those designed to move upon impact, demand specialized mounting to function correctly and safely. Failure to account for these specific needs can result in malfunction, damage to the support structure, or hazardous conditions. Therefore, the design process begins with clear identification of the target type to inform material selection, structural design, and mounting mechanisms.

In summary, target compatibility directly governs the success of a construction project. The design considerations extend beyond mere dimensions to encompass material strength, mounting methods, and overall stability relative to the target’s characteristics. Neglecting this interplay compromises functionality and safety, highlighting the importance of meticulous planning and tailored design. The practical significance is clear: a well-matched support maximizes the usability of the target, enhancing training or recreational shooting activities.

4. Portability Considerations

Portability represents a significant factor influencing the design and utility of personal target support systems. The ease with which a device can be transported and deployed directly impacts its suitability for diverse shooting environments and user preferences. Designs prioritizing portability often require compromises in other areas, such as structural robustness or target size capacity.

- Weight and Material Selection

The overall weight of the structure fundamentally determines its portability. Lighter materials, such as aluminum or thin-walled steel, facilitate easier transport compared to heavier alternatives like solid wood or thick-gauge steel. However, reducing weight may necessitate sacrificing structural integrity or impact resistance. For instance, a lightweight aluminum frame may be easily carried but susceptible to damage from wind or accidental impact. Conversely, a heavier wooden frame provides superior stability but poses logistical challenges for a single individual to move. These trade-offs are central.

- Disassembly and Collapsibility

The ability to disassemble or collapse the structure into a more compact form significantly enhances portability, particularly for transport in vehicles with limited cargo space. Modular designs, incorporating detachable legs or folding frames, allow for convenient storage and transport. However, complex disassembly mechanisms can add to the overall weight and require specialized tools. A simple A-frame design that folds flat offers a balance between portability and ease of use. Intricate designs, while compact when collapsed, may prove cumbersome to assemble in the field.

- Carry Handles and Transportation Aids

The inclusion of carry handles or provisions for attaching straps or wheels greatly improves ease of transport. Ergonomic handles facilitate comfortable lifting and carrying, while straps allow the device to be slung over the shoulder or attached to a backpack. Wheels transform a stationary structure into a mobile unit, enabling effortless movement across various terrains. A basic wooden frame with a simple handle provides adequate portability for short distances, while more elaborate designs may incorporate telescoping handles and integrated wheels for enhanced maneuverability. The integration must be aligned with requirements.

- Durability During Transit

A portable structure must withstand the rigors of transportation without sustaining damage. Exposed components are vulnerable to bending or breaking during transit, necessitating protective measures. Reinforced joints, padded carrying bags, or durable storage containers mitigate the risk of damage. A collapsible steel frame, while lightweight, may require a padded bag to prevent scratches or dents during transport. A wooden frame may need reinforcement at the joints to prevent breakage from rough handling. Ensuring transit durability preserves long-term utility.

The facets outlined above clearly demonstrate that “Portability Considerations” are intertwined with design and material decisions. Effective design optimizes the ease of transporting and deploying supports without compromising their functionality or structural integrity. Striking an appropriate balance between these conflicting requirements is crucial for creating a practical and user-friendly product.

5. Safety Protocols

The implementation of rigorous safety protocols is inextricably linked to the construction and use of personal target support systems. Neglecting safety considerations during the design, construction, or deployment phases can result in significant risks, including projectile ricochet, structural failure leading to injury, and unintended damage to property. Adherence to established guidelines and best practices is therefore paramount to ensuring a safe shooting environment.

- Material Selection for Ricochet Mitigation

The choice of materials used in construction directly influences the likelihood of projectile ricochet. Hard, non-yielding surfaces, such as steel plates positioned at acute angles relative to the shooter, significantly increase the risk of ricochet. Conversely, the incorporation of softer, energy-absorbing materials, like rubber sheeting or angled wooden baffles, reduces the likelihood of a projectile deflecting back towards the firing line. Real-world incidents demonstrate the potential consequences of improper material selection, ranging from minor injuries to severe bodily harm. A support incorporating a steel plate without proper angling or baffling mechanisms presents a clear safety hazard.

- Structural Stability and Collapse Prevention

The structural integrity of the target support is crucial for preventing accidental collapse, which can expose individuals to flying debris or create an unstable shooting platform. Inadequate design, substandard materials, or improper assembly techniques compromise structural stability. Regular inspection for signs of wear, corrosion, or damage is essential. A support constructed from untreated lumber and assembled with insufficient fasteners may fail under the weight of a steel target or during windy conditions, potentially resulting in injury or property damage. The adherence to sound engineering principles during design and construction mitigates this risk.

- Clear Delineation of Safe Zones and Backstops

Establishing clearly defined safe zones and ensuring an adequate backstop are critical for preventing unintended impacts beyond the target area. A properly constructed backstop, composed of earth berms, sandbags, or purpose-built ballistic barriers, contains projectiles and minimizes the risk of stray shots causing damage or injury. The absence of a clearly defined safe zone and an adequate backstop creates an unacceptable level of risk. The use of highly visible signage to delineate the safe shooting area further enhances safety awareness.

- Consistent Application of Safe Shooting Practices

The construction of a safe and functional target support does not obviate the need for consistent application of established safe shooting practices. Proper firearm handling, adherence to range rules, and the use of appropriate personal protective equipment (eye and ear protection) remain essential elements of a safe shooting environment. Even the most robust and well-designed target support cannot compensate for negligent firearm handling. Continuous reinforcement of safe shooting practices is integral to minimizing risk.

The foregoing facets underscore the profound and inseparable link between safety protocols and personal target supports. A comprehensive approach that integrates sound design principles, appropriate material selection, diligent construction practices, and unwavering adherence to safe shooting practices minimizes risk and ensures a secure and enjoyable shooting experience. Failure to prioritize safety compromises not only individual well-being but also the sustainability of shooting sports.

6. Weather Resistance

Weather resistance, as applied to the construction of devices for supporting targets, represents a critical design consideration that directly influences the longevity, structural integrity, and overall cost-effectiveness of the finished product. Exposure to environmental elements, including moisture, ultraviolet radiation, and temperature fluctuations, can degrade materials, weaken joints, and ultimately compromise the functionality of the support structure. Therefore, proactive integration of weather-resistant features is essential for ensuring durable and reliable performance, particularly for supports intended for long-term outdoor use.

- Material Selection for Environmental Durability

The choice of materials constitutes the first line of defense against weather-related degradation. Pressure-treated lumber, known for its resistance to rot and insect infestation, offers a significant advantage over untreated wood in outdoor applications. Similarly, metal components, such as steel tubing, require protective coatings, like galvanization or powder coating, to prevent corrosion. The selection of fasteners, such as stainless steel screws or bolts, further minimizes the risk of rust and material incompatibility. The use of untreated wood in a humid environment results in rapid deterioration, whereas the implementation of weather-resistant materials significantly extends service life.

- Protective Coatings and Sealants

The application of protective coatings and sealants provides an additional layer of defense against moisture penetration and ultraviolet radiation damage. Exterior-grade paints, varnishes, and stains create a barrier that repels water and blocks harmful UV rays, preventing premature fading, cracking, and warping of the underlying materials. Sealants applied to joints and seams prevent water from seeping into vulnerable areas, minimizing the risk of rot and corrosion. A properly applied coating extends the service life of the structure.

- Design Features for Water Drainage

Incorporating design features that promote water drainage minimizes the accumulation of moisture on the support structure. Angled surfaces, drainage holes, and elevated platforms prevent water from pooling and creating conditions conducive to rot and corrosion. The design minimizes contact with standing water, lessening deterioration. Proper water management, through design, is an important countermeasure.

- Ultraviolet (UV) Radiation Mitigation

Prolonged exposure to ultraviolet radiation degrades many materials, causing them to become brittle, discolored, and structurally weaker. The application of UV-resistant coatings, such as those found in marine-grade paints, mitigates the harmful effects of UV exposure. Shading the support structure, when feasible, provides additional protection. Consideration of UV resistance factors into material selection and protective measures.

The multifaceted approach to weather resistance outlined above emphasizes its importance in the creation of personal target support systems intended for outdoor use. Selecting appropriate materials, applying protective coatings, incorporating design features for water drainage, and mitigating the effects of UV radiation collectively contribute to a durable and long-lasting structure. Neglecting these considerations results in premature failure, increased maintenance costs, and potentially unsafe shooting conditions. A proactive approach to weather resistance is an investment in the long-term functionality and safety of the support.

7. Cost Efficiency

Cost efficiency serves as a primary motivator for many individuals engaged in creating personal target supports. The ability to construct functional and durable devices at a fraction of the cost of commercially available alternatives presents a tangible economic advantage, particularly for those frequently participating in shooting activities. However, true cost efficiency extends beyond simply minimizing initial expenses; it encompasses long-term durability, reduced maintenance requirements, and the avoidance of potential safety hazards that could result in costly repairs or injuries.

- Material Sourcing and Repurposing

Strategic material sourcing represents a key component of cost-efficient construction. Utilizing reclaimed or repurposed materials, such as discarded lumber, metal scraps, or used tires, significantly reduces expenses compared to purchasing new materials. However, caution must be exercised to ensure that repurposed materials are structurally sound and free from contaminants that could pose a safety risk. Examples include using old pallets as a framework after careful inspection for broken boards or sourcing metal tubing from scrap yards for constructing target frames. Prudent selection balances cost savings with safety.

- Design Simplicity and Minimization of Waste

Embracing simple, efficient designs minimizes material waste and reduces construction time, thereby lowering overall costs. Complex designs often require specialized tools, intricate cuts, and increased material usage, negating potential cost savings. Opting for straightforward designs that utilize readily available materials and basic construction techniques proves more cost-effective. Examples include a basic A-frame target stand constructed from a few pieces of lumber or a simple steel frame designed to hold a single target. Efficiency in design minimizes both material costs and labor investment.

- Tool Investment vs. Material Costs

A careful evaluation of tool requirements is essential for achieving cost efficiency. While purchasing specialized tools can facilitate more complex designs or improve construction speed, the initial investment may outweigh the potential savings in material costs. Utilizing existing tools or borrowing specialized equipment from friends or neighbors can significantly reduce overall expenses. Consider whether a one-time tool purchase will offset the long-term cost of materials. The cost of tools factors into financial considerations.

- Longevity and Reduced Replacement Costs

Investing in durable materials and robust construction techniques, while potentially increasing initial expenses, can lead to significant cost savings over the long term by reducing the need for frequent repairs or replacements. Supports constructed from weather-resistant materials and designed to withstand the rigors of regular use offer a superior return on investment compared to cheaper, less durable alternatives. A target stand constructed from pressure-treated lumber or coated steel may cost more upfront, but its extended lifespan and reduced maintenance requirements ultimately translate to lower overall costs. Long-term durability delivers ongoing cost savings.

In conclusion, cost efficiency in the creation of personal target supports is achieved through a holistic approach that considers material sourcing, design simplicity, tool investment, and long-term durability. The most cost-effective solutions balance initial expenses with ongoing maintenance requirements and the potential for increased longevity. A well-planned and executed construction project minimizes costs while maximizing functionality and safety, representing a prudent investment for shooting sports participants.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding the construction of personal target support systems. The information provided aims to offer clarity and guidance for individuals undertaking such projects.

Question 1: What constitutes the most critical safety consideration during target support construction?

Preventing projectile ricochet represents the paramount safety consideration. Proper angling of target surfaces and the incorporation of energy-absorbing materials mitigate the risk of projectiles deflecting back towards the firing line.

Question 2: Is it permissible to utilize any available material in the creation of a target support?

The indiscriminate use of materials is not advised. Materials must exhibit sufficient structural integrity to withstand the intended use and environmental conditions. The potential for material degradation or hazardous composition must be evaluated.

Question 3: How does the choice of materials impact the lifespan of a target support system?

Material selection significantly affects the longevity of the support. Weather-resistant materials, such as pressure-treated lumber or coated steel, extend the lifespan compared to materials susceptible to rot, corrosion, or UV degradation.

Question 4: Does the weight of the target to be used affect the design of the support structure?

The target’s weight is a critical design factor. The support must possess sufficient load-bearing capacity to prevent collapse or instability. Heavier targets necessitate more robust construction and a wider, more stable base.

Question 5: Is portability a necessary consideration for all target support systems?

Portability is not always essential, but it enhances the versatility of the support. Designs prioritizing portability may incorporate lightweight materials, collapsible frames, or carrying handles to facilitate transport and deployment in various locations.

Question 6: Does the type of firearm used influence the design requirements of the support structure?

While the firearm itself does not directly dictate support design, the projectiles used and the anticipated impact energy are relevant. Higher-caliber firearms firing projectiles with greater kinetic energy may necessitate more robust backstops or target mounting systems.

The information presented addresses key considerations related to safe and effective construction practices. Careful planning and adherence to established guidelines are crucial for ensuring a positive outcome.

The subsequent section will address potential sources for obtaining design plans and construction guidance.

Concluding Thoughts on Shooting Target Stands DIY

The preceding exploration of constructing personalized target support devices underscores the multifaceted nature of the undertaking. Considerations range from material selection and structural integrity to safety protocols and weather resistance. The successful creation of reliable target stands requires diligent planning, careful execution, and a thorough understanding of the principles governing structural stability and projectile dynamics.

The endeavor extends beyond mere cost savings. The design and construction of shooting target stands DIY projects represent an opportunity for skill development and a tangible demonstration of self-reliance. Prudent execution and adherence to established safety standards are paramount. These guidelines offer a foundational framework for practitioners engaging in these activities. The careful application of provided information should promote safe, effective, and enduring performance.