Structures crafted from repurposed wooden shipping platforms and intended to support a mattress constitute a low-cost, customizable foundation for sleep. These constructions involve disassembling, modifying, and reassembling the pallets to achieve the desired size, height, and aesthetic. An example includes a platform built from four standard-sized pallets arranged in a square, creating a full-size bed frame.

The utilization of recycled materials for bedroom furniture offers several advantages. These include reduced expenditure compared to commercially manufactured bed frames, promotion of environmental sustainability through material reuse, and opportunity for personalized design. Historically, resourcefulness in furniture construction has been a necessity during periods of economic hardship, evolving into a contemporary trend emphasizing upcycling and individual expression.

The subsequent discussion will delve into specific aspects of constructing these platforms, covering material selection, preparation techniques, assembly methods, and safety considerations. Detailed instructions and alternative design options will also be presented to facilitate successful creation of these customized sleeping platforms.

Construction Guidelines

Successful creation of sleeping platforms using recycled shipping platforms requires careful planning and execution. The following guidelines provide critical information for a durable and safe finished product.

Tip 1: Source Pallets Judiciously: Select pallets marked with the IPPC stamp, indicating heat treatment rather than chemical fumigation. Avoid pallets with visible signs of damage, mold, or stains.

Tip 2: Prioritize Surface Preparation: Thoroughly clean each pallet with soap and water. Sand all surfaces to remove splinters and rough edges, ensuring a smooth and safe sleeping surface.

Tip 3: Reinforce Structural Integrity: Strengthen pallet connections by adding additional screws or nails to all joints. Consider using metal brackets for enhanced stability, especially for larger bed sizes.

Tip 4: Accurate Measurement is Essential: Precisely measure the mattress dimensions to ensure the platform provides adequate support without excessive overhang. Plan for any desired headboard or footboard additions during the initial measurement phase.

Tip 5: Implement Proper Ventilation: Design the platform with sufficient airflow beneath the mattress to prevent moisture buildup and potential mold growth. This can be achieved through spacing between pallets or the inclusion of vertical supports.

Tip 6: Apply Protective Finishes: Seal the wood with a non-toxic sealant or paint to protect against moisture, stains, and wear. Allow the finish to fully cure before placing the mattress on the platform.

Tip 7: Secure the Structure: If constructing a multi-level platform, securely fasten each pallet layer to the others using screws or construction adhesive. This prevents shifting and enhances overall stability.

Adhering to these recommendations will contribute significantly to a sturdy, aesthetically pleasing, and safe sleeping platform constructed from reclaimed shipping platforms.

The subsequent sections will explore aesthetic customization options and address common troubleshooting issues encountered during construction.

1. Material Selection

The viability of a platform constructed from reclaimed shipping platforms hinges critically on careful material selection. The choice of pallets directly affects the structural integrity, safety, and longevity of the finished bed frame. Specifically, the type of wood, its treatment, and its physical condition are all paramount considerations. For example, pallets marked with an IPPC (International Plant Protection Convention) stamp, signifying heat treatment, are preferable to those treated with methyl bromide, a fumigant considered hazardous. The heat treatment process eliminates potential pests and reduces the risk of chemical exposure. Utilizing damaged or heavily weathered pallets can compromise the structural stability of the bed frame, potentially leading to collapse or injury. Therefore, a meticulous inspection for cracks, rot, and insect infestation is an essential preliminary step in the construction process.

Furthermore, the specific dimensions and construction of the pallets influence the overall design and ease of assembly. Standardized pallet sizes streamline the building process, while variations necessitate more complex modifications. For instance, using pallets of consistent dimensions allows for simple, modular arrangements, whereas incorporating dissimilar sizes requires cutting, joining, and careful alignment to achieve a level and stable sleeping surface. Real-world examples demonstrate that projects utilizing mismatched or substandard pallets frequently encounter structural weaknesses, uneven surfaces, and accelerated wear and tear. The implementation of stringent material selection protocols mitigates these risks and ensures a durable and reliable end product.

In conclusion, the selection of appropriate pallets is not merely a logistical consideration but a determinant of the project’s ultimate success. Prioritizing heat-treated, structurally sound pallets of uniform size ensures the creation of a safe, stable, and aesthetically pleasing sleeping platform. Overlooking these critical material considerations can lead to compromised structural integrity, potential safety hazards, and ultimately, the premature failure of the entire structure. Therefore, a diligent and informed approach to material selection is indispensable for any construction undertaking using reclaimed shipping platforms.

2. Surface Preparation

Surface preparation is a foundational element in the construction of sleeping platforms from reclaimed shipping platforms. The effectiveness of this preparation significantly impacts the finished product’s aesthetic appeal, structural integrity, and user safety. Proper preparation methods mitigate potential hazards and enhance the overall quality and lifespan of the structure.

- Cleaning and Disinfection

Shipping platforms often accumulate dirt, grime, and potential contaminants during transit and storage. Thorough cleaning with soap and water, followed by disinfection with a suitable cleaning agent, removes these impurities. This step minimizes the risk of introducing allergens or harmful substances into the sleeping environment. For example, failure to adequately clean a pallet could result in mold growth, leading to respiratory issues for the user.

- Sanding and Smoothing

Raw shipping platforms typically exhibit rough surfaces, splinters, and sharp edges. Sanding these surfaces with progressively finer grit sandpaper creates a smooth and even texture. This process not only improves the aesthetic appearance of the bed frame but also eliminates potential injury hazards. A bed frame left unsanded could lead to splinters or cuts, compromising user safety.

- Addressing Imperfections and Repairs

Inspection of each shipping platform reveals potential imperfections such as cracks, loose nails, or damaged sections. Addressing these issues prior to assembly ensures structural stability and prevents future complications. Filling cracks with wood filler, replacing loose nails with screws, and reinforcing weakened areas enhance the durability and longevity of the bed frame. Ignoring these imperfections can lead to structural failure or instability over time.

- Application of Sealants and Finishes

Sealing the prepared surfaces with a protective finish, such as a non-toxic sealant or paint, shields the wood from moisture, stains, and wear. This step enhances the aesthetic appeal of the bed frame while also providing a barrier against potential environmental damage. Untreated wood is susceptible to moisture absorption, which can lead to warping, cracking, or decay.

In summary, the meticulous execution of surface preparation techniques is critical for the successful construction of sleeping platforms from reclaimed shipping platforms. Each element of the process contributes to a safer, more durable, and aesthetically pleasing finished product. Neglecting these preparatory steps increases the risk of structural instability, user injury, and reduced lifespan of the constructed bed frame.

3. Structural Reinforcement

The long-term viability of sleeping platforms constructed from reclaimed shipping platforms is intrinsically linked to the implementation of effective structural reinforcement techniques. Absent adequate reinforcement, these platforms are prone to instability, collapse, and premature failure. The inherently modular nature of pallet construction introduces potential weak points at connection sites. Therefore, supplementing the existing structure with additional support is crucial.

Consider, for example, a basic platform design utilizing four standard-sized pallets. The connection between these four individual units represents a critical area for reinforcement. Simple screwing or nailing alone may prove insufficient to withstand the constant weight and movement associated with regular use. Real-world examples demonstrate instances where such minimally reinforced platforms exhibit sagging, joint separation, and eventual structural compromise. Conversely, platforms incorporating metal brackets, additional wooden supports, and high-strength fasteners demonstrate significantly enhanced stability and longevity. In practice, these additions can involve strategically placed angle brackets at pallet junctions, the incorporation of a central support beam spanning the width of the platform, or the application of construction adhesive to augment mechanical fasteners.

Consequently, structural reinforcement constitutes a non-negotiable element in the construction of durable and safe sleeping platforms from reclaimed shipping platforms. These measures directly mitigate the risk of structural failure and prolong the service life of the finished product. Overlooking these essential reinforcement techniques can result in compromised structural integrity, potential safety hazards, and ultimately, the premature failure of the structure. The implementation of robust reinforcement protocols is, therefore, paramount to achieving a stable, secure, and enduring sleeping surface.

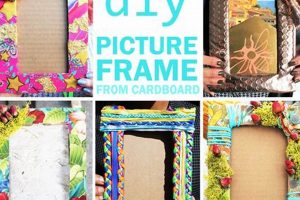

4. Design Customization

The inherent versatility of reclaimed shipping platforms lends itself profoundly to design customization within the realm of do-it-yourself bed frame construction. The modular nature of pallets facilitates adaptations in size, configuration, and aesthetic appearance, enabling personalized sleeping platforms that transcend the limitations of mass-produced furniture.

- Dimensional Adaptation

Pallet bed frame construction allows for precise tailoring to accommodate mattresses of varying dimensions. Standard pallet sizes can be modified through cutting and reassembly to achieve exact length and width specifications. Examples include constructing platforms for less common mattress sizes, such as California King or custom-sized mattresses for unique room layouts. Failure to adapt dimensions can result in inadequate mattress support or an aesthetically unappealing overhang.

- Height Modulation

The elevation of the sleeping surface can be readily adjusted by stacking pallets to the desired height. This feature accommodates individual preferences for bed height, facilitating ease of access and egress. A lower profile might be preferred for minimalist aesthetics, while a higher platform provides additional under-bed storage. Improper height calculation can lead to difficulties in getting in and out of bed or insufficient storage space.

- Integrated Storage Solutions

The inherent voids within pallet structures can be repurposed for integrated storage. Drawers, shelves, or open cubbies can be incorporated into the pallet framework, maximizing space utilization within the bedroom. An example includes adding sliding drawers beneath the platform for clothing or bedding storage. Neglecting to consider integrated storage opportunities represents a missed opportunity for optimizing space and functionality.

- Aesthetic Personalization

The surface of the pallet structure provides a canvas for aesthetic personalization through paint, stain, or decorative elements. The raw, rustic appearance of the wood can be preserved for a natural aesthetic, or it can be transformed through the application of color and texture. Examples include painting the platform to complement existing room dcor or adding reclaimed wood accents for visual interest. Inadequate aesthetic planning can result in a visually unappealing or incongruous bed frame.

These facets of design customization underscore the unique advantages of using reclaimed shipping platforms for bed frame construction. The ability to tailor dimensions, modulate height, integrate storage, and personalize aesthetics empowers individuals to create sleeping platforms that precisely meet their functional and stylistic requirements, resulting in bespoke furniture pieces that reflect personal preferences and spatial constraints.

5. Safety Implementation

The construction of sleeping platforms from repurposed shipping platforms necessitates rigorous attention to safety protocols. These structures, while offering cost-effectiveness and aesthetic appeal, present inherent risks if safety measures are inadequately addressed. The selection of appropriate materials, the execution of proper assembly techniques, and the mitigation of potential hazards are all inextricably linked to the overall safety and longevity of the completed bed frame. Failure to prioritize these elements can result in structural instability, potential injury, and the introduction of harmful substances into the sleeping environment. For instance, pallets treated with chemical fumigants, if used without proper identification and preparation, can release volatile organic compounds (VOCs) into the air, posing a health risk to occupants. Similarly, insufficiently sanded surfaces can cause splinters and abrasions, while unstable construction can lead to collapse, potentially resulting in serious injury.

Practical application of safety protocols involves several key steps. First, sourcing pallets from reputable vendors and verifying their treatment history is paramount. Pallets marked with the IPPC stamp indicating heat treatment are generally preferable to those treated with chemical fumigants like methyl bromide. Second, thorough cleaning and sanding of all surfaces are essential to remove dirt, grime, and potential contaminants. Sanding also eliminates sharp edges and splinters, reducing the risk of injury. Third, robust structural reinforcement techniques, such as the use of metal brackets and high-strength fasteners, are critical for ensuring stability and preventing collapse. Real-world examples demonstrate that platforms constructed without adequate reinforcement are prone to sagging, joint separation, and eventual structural failure. Regular inspection and maintenance of the platform are also vital for identifying and addressing potential hazards before they escalate into serious problems.

In conclusion, the effective implementation of safety measures is not merely an ancillary consideration in the construction of sleeping platforms from repurposed shipping platforms; it is a fundamental prerequisite for ensuring the well-being of users. Prioritizing material selection, employing sound construction techniques, and mitigating potential hazards are essential for creating a safe, durable, and aesthetically pleasing sleeping environment. The challenges associated with safety implementation underscore the importance of diligent planning, meticulous execution, and ongoing vigilance in all phases of the construction process. By integrating robust safety protocols, individuals can harness the benefits of repurposed shipping platforms while minimizing the associated risks.

Frequently Asked Questions

The following addresses common inquiries regarding the construction and utilization of sleeping platforms built from repurposed shipping pallets. This information aims to provide clarity on safety, durability, and practical considerations.

Question 1: Are reclaimed shipping platforms safe for use as bed frames?

The safety of using reclaimed shipping platforms as bed frames hinges on several factors. Pallets treated with methyl bromide, a fumigant, pose a health risk and should be avoided. Pallets marked with an IPPC stamp indicating heat treatment are generally safer. Furthermore, thorough cleaning, sanding, and sealing of the wood are essential to minimize exposure to potential contaminants and prevent splinters.

Question 2: How durable are sleeping platforms made from reclaimed shipping platforms?

Durability depends on the quality of the pallets and the assembly techniques employed. Pallets with visible damage, rot, or insect infestation are unsuitable. Reinforcing joints with metal brackets and using appropriate fasteners enhances structural integrity and prolongs the lifespan of the platform. Proper weight distribution and adherence to recommended load capacities are also crucial.

Question 3: What is the best method for cleaning reclaimed shipping platforms before construction?

The recommended cleaning method involves scrubbing the pallets with a solution of soap and water. A stiff brush is useful for removing dirt and debris from crevices. Disinfection with a diluted bleach solution may be considered, followed by thorough rinsing and drying. Ensuring complete dryness prevents mold growth and protects the wood from deterioration.

Question 4: How can mold growth be prevented in sleeping platforms constructed from reclaimed shipping platforms?

Preventing mold growth requires selecting pallets free from existing mold, ensuring adequate ventilation beneath the mattress, and applying a moisture-resistant sealant to the wood. Regular inspection for signs of mold and prompt action to address any moisture issues are also essential. Consider using a mattress with breathable materials to minimize moisture buildup.

Question 5: What type of finish is recommended for sealing a reclaimed shipping platform bed frame?

A non-toxic sealant or paint specifically formulated for wood is recommended. Choose a product that is low in volatile organic compounds (VOCs) to minimize potential health risks. Several coats may be necessary to achieve adequate protection. Allow the finish to fully cure before placing the mattress on the platform.

Question 6: Are there weight restrictions for sleeping platforms constructed from reclaimed shipping platforms?

Yes, there are weight restrictions. The load capacity of a pallet bed frame depends on the type and condition of the pallets used, as well as the assembly method. Overloading the platform can lead to structural failure. Distributing weight evenly and avoiding excessive point loads are important considerations. Consult pallet specifications or seek professional advice for accurate weight capacity assessments.

In summary, safety, durability, and longevity depend on diligent material selection, proper preparation, and adherence to recommended construction techniques. Taking precautions ensures a safe and reliable sleeping platform.

The subsequent section will address potential challenges and troubleshooting tips for constructing these platforms.

Conclusion

This exploration of diy pallet bed frames underscores the importance of informed decision-making in their construction. Material selection, preparation rigor, and structural reinforcement are not merely procedural steps, but determinants of safety and longevity. Neglecting these critical elements risks compromised structural integrity and potential health hazards.

The information presented herein should serve as a foundation for responsible implementation. Prospective builders are urged to prioritize safety above all else, consulting with relevant experts and adhering to established building codes where applicable. The responsible repurposing of materials can be both cost-effective and environmentally sound, but only when executed with due diligence and unwavering commitment to safety standards.