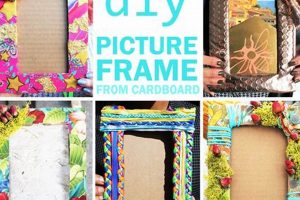

Creative enhancements applied to the borders of reflective surfaces offer personalized aesthetics within interior spaces. For example, seashells affixed to a circular looking glass create a coastal-themed accent.

Customizing the perimeters of reflective surfaces yields cost-effective and visually unique dcor elements. Historically, these enhancements have served as both artistic expression and functional integration with existing design schemes, increasing perceived value.

The subsequent sections will detail a variety of techniques and materials suited for customizing the perimeters of reflective surfaces, providing practical guidance for diverse design preferences and skill levels.

Enhancing Reflective Surfaces

The following guidelines are designed to optimize the execution and impact of personalized mirror enhancements, ensuring a professional and aesthetically pleasing result.

Tip 1: Material Selection. Prioritize materials compatible with the mirror’s environment. High-humidity areas necessitate water-resistant adhesives and finishes to prevent degradation.

Tip 2: Surface Preparation. Thoroughly clean the existing frame or the mirror’s edge with a suitable solvent. This ensures optimal adhesion and prevents contamination of the applied materials.

Tip 3: Accurate Measurement. Precisely measure the dimensions of the frame area. Accurate measurements minimize material waste and ensure a seamless, professional finish.

Tip 4: Adhesive Application. Employ appropriate adhesive for the chosen material. Distribute adhesive evenly and avoid excessive application, which can lead to unsightly seepage.

Tip 5: Secure Attachment. Ensure all decorative elements are firmly affixed. Clamping or bracing may be necessary during the adhesive’s curing process.

Tip 6: Consider the Existing Decor. Select materials and designs that complement the existing room decor to ensure visual harmony.

Tip 7: Safety Precautions. Always use safety glasses and gloves when cutting or applying materials. Work in a well-ventilated area, especially when using adhesives or solvents.

Adherence to these guidelines will contribute to a polished and enduring final product, elevating the aesthetic appeal of reflective surfaces within any interior space.

The subsequent section will address common challenges encountered during the customization of reflective surfaces, offering solutions to ensure successful project completion.

1. Material Compatibility

Material compatibility is a fundamental consideration in the successful execution of reflective surface enhancement projects. The selection of inappropriate materials can lead to premature degradation, structural instability, and aesthetic failures. For example, using porous, non-sealed wood as a frame in a humid environment, such as a bathroom, will inevitably result in moisture absorption, warping, and eventual decay. Conversely, selecting materials resistant to environmental factors ensures the longevity and visual integrity of the customized piece. The cause-and-effect relationship is direct: incompatible materials cause deterioration; compatible materials promote durability.

The selection process necessitates a thorough understanding of the material’s properties relative to its intended environment. Acrylic paints, for instance, provide water resistance and flexibility, making them suitable for frames exposed to fluctuating temperatures or humidity levels. Similarly, utilizing adhesives formulated for specific materials, such as glass or metal, guarantees a secure and lasting bond. Real-life examples include using epoxy resin with embedded natural elements for a unique finish, or employing specialized metal paints for a sleek, modern look on metal-framed reflective surfaces.

In summary, material compatibility is not merely a secondary consideration, but a critical component of reflective surface enhancement. Ignoring this factor can result in costly repairs or replacements, negating the cost-effectiveness of a do-it-yourself approach. By prioritizing materials that are both aesthetically pleasing and functionally appropriate, project durability and visual appeal is assured. This understanding aligns directly with the broader theme of crafting sustainable and enduring interior accents.

2. Adhesive Strength

Adhesive strength directly impacts the structural integrity and longevity of customized reflective surface frames. Insufficient adhesive strength results in detachment of decorative elements or frame components, compromising the aesthetic appeal and potentially creating safety hazards. The causal relationship is clear: weak adhesive yields impermanence, while robust adhesive ensures durability. As a critical component of reflective surface enhancement projects, appropriate adhesive selection is paramount.

The type of adhesive must correspond to the materials being joined. For instance, bonding heavy embellishments to a glass surface requires a high-strength epoxy or a specialized glass adhesive. Construction-grade adhesives are often suitable for attaching wood frames to a substrate. Failure to select the correct adhesive can lead to bond failure, particularly in environments with temperature fluctuations or high humidity. A practical example includes using a solvent-based adhesive for adhering plastic elements to a metal frame, ensuring a lasting bond that withstands environmental stressors.

In summary, appropriate adhesive strength is not merely a detail but a prerequisite for success in customizing reflective surface frames. This necessitates careful consideration of material compatibility, environmental factors, and the weight of decorative components. Selecting the correct adhesive and applying it according to manufacturer instructions ensures a durable, visually pleasing result, effectively addressing a primary challenge in reflective surface enhancement. This detailed understanding reinforces the importance of informed decision-making in achieving enduring and aesthetically satisfying outcomes.

3. Measurement Precision

Measurement precision forms a foundational element for successful reflective surface enhancement. Its significance resides in ensuring dimensional accuracy, minimizing material waste, and achieving a seamless integration of decorative elements.

- Material Quantity Optimization

Precise measurements directly correlate with efficient material utilization. Inaccurate dimensions lead to overestimation or underestimation of required materials, resulting in financial losses and potential project delays. For instance, calculating the exact perimeter of a reflective surface frame before purchasing decorative trim ensures sufficient material without excess, promoting cost-effectiveness. In real-world scenarios, this translates to significant savings on materials such as wood, tiles, or decorative rope.

- Seamless Integration of Elements

Accurate measurements are essential for creating a visually harmonious design. When adding mosaic tiles or individual decorative components, precise dimensions ensure uniform spacing and alignment. Deviations from accurate measurements manifest as visible gaps, uneven patterns, and a lack of professional polish. This is exemplified by carefully measuring and cutting tiles to fit the frame perfectly, resulting in a flawless and aesthetically pleasing finish.

- Structural Stability and Fit

Particularly when constructing a new frame, measurement precision is paramount for ensuring structural integrity. Inaccurate dimensions can result in a frame that is too small, too large, or improperly aligned with the reflective surface. This not only compromises the visual appeal but also potentially jeopardizes the stability of the entire assembly. For example, when building a wooden frame, precise measurements of the reflective surface’s dimensions guarantee a snug, secure fit, preventing movement or warping.

- Reduced Waste and Rework

Accurate measurement significantly reduces material waste and the need for rework. When dimensions are off, materials must be recut or replaced, leading to increased costs and time investment. This is especially critical when working with expensive or difficult-to-source materials. A prime example includes accurately cutting glass tiles for a mosaic design; precise measurements minimize breakage and ensure a seamless, professional appearance.

In summary, measurement precision is not merely a technical detail but a critical determinant of success in reflective surface enhancement projects. Prioritizing accurate measurements translates to cost savings, enhanced aesthetics, structural integrity, and reduced project time, underscoring its vital role in achieving professional-quality results.

4. Surface Preparation

Surface preparation forms a critical precursor to successful execution of reflective surface frame customization. The causal relationship is evident: inadequate preparation yields compromised adhesion, diminished aesthetic quality, and potential project failure, whereas proper preparation facilitates optimal bonding, enhanced visual appeal, and enduring results.

The importance of surface preparation within the context of customizing reflective surface frames stems from its direct influence on adhesion. Contaminants such as dust, grease, or existing finishes impede the bond between the frame and the reflective surface, or between decorative elements and the frame itself. A real-life example involves attempting to adhere mosaic tiles to a frame without first removing a glossy coating; the tiles would likely detach over time due to poor adhesion. Effective surface preparation, conversely, involves cleaning the surface with appropriate solvents, sanding to create a textured surface, and applying a primer to promote bonding. This ensures that adhesives and finishes adhere correctly, resulting in a durable and aesthetically pleasing outcome. Specifically, for wooden frames, sanding and priming are crucial to create an even surface for paint or other finishes. For metal frames, degreasing and etching may be necessary to ensure proper adhesion. Glass surfaces require cleaning with specialized glass cleaners to remove any residue that might interfere with adhesive bonding.

In summary, surface preparation is not merely a preliminary step but an essential component of reflective surface frame customization. Neglecting this aspect compromises the integrity and longevity of the project, leading to potential rework or complete failure. Prioritizing thorough and appropriate surface preparation guarantees enhanced adhesion, superior aesthetics, and enduring results, aligning with the overall goal of creating lasting and visually appealing interior accents.

5. Design Cohesion

Design cohesion, in the context of customizing reflective surface perimeters, refers to the harmonious integration of the frame’s aesthetic characteristics with the surrounding environment and the reflective surface itself. This integration considers factors such as color palettes, material choices, and stylistic motifs to create a unified visual narrative.

- Color Palette Integration

The chosen colors for the frame should complement the dominant hues in the room or the colors reflected within the reflective surface. For example, a bathroom with cool, muted tones might benefit from a frame incorporating seafoam green or pale blue, reinforcing the existing aesthetic. A frame utilizing jarring or clashing colors disrupts visual harmony and detracts from the overall design. Real-world implementation might include extracting the accent color from a piece of artwork and replicating it within the frame’s design.

- Material Consistency

Materials selected for the frame should align with the existing textures and materials present in the room. A rustic living room, for example, might benefit from a wooden frame with a distressed finish, while a modern space could incorporate sleek metal or minimalist acrylic. Introducing materials that are incongruent with the existing design can create a sense of visual dissonance. Using reclaimed wood in a farmhouse-style setting is a practical example of achieving material consistency.

- Stylistic Motif Alignment

The stylistic motif of the frame should resonate with the overarching design theme of the space. A room decorated in a mid-century modern style would be best complemented by a frame with clean lines and geometric shapes, whereas a bohemian setting might call for a frame adorned with macram or natural elements. Introducing a conflicting stylistic motif can appear disjointed and unintentional. A nautical-themed bathroom, for instance, would logically feature a frame incorporating rope or seashells.

- Scale and Proportion Consideration

The size and proportion of the frame relative to the reflective surface and the surrounding space are critical for achieving design cohesion. An overly ornate or excessively large frame can overwhelm a small reflective surface or a compact room, while an undersized frame may appear insignificant and lacking impact. Achieving the appropriate scale involves assessing the dimensions of the reflective surface and the room, ensuring that the frame complements rather than dominates the visual landscape.

These facets of design cohesion are essential considerations during reflective surface customization. Thoughtful application of these principles results in a customized reflective surface that enhances rather than detracts from the overall aesthetic of the space, contributing to a unified and visually pleasing interior.

6. Safety Practices

The integration of appropriate safety measures is paramount during the execution of reflective surface frame customization projects. The absence of such precautions introduces significant risks of physical harm and property damage, thereby necessitating a comprehensive understanding and diligent application of safety protocols.

- Eye Protection

The use of safety eyewear is imperative when cutting, sanding, or applying adhesives or finishes. Airborne particles and chemical splashes pose a direct threat to ocular health, potentially resulting in temporary or permanent vision impairment. Real-world scenarios such as cutting glass tiles for mosaic designs or sanding wooden frames generate particulate matter that can cause corneal abrasions or chemical burns. Consistent use of safety glasses or goggles mitigates these risks. This is non-negotiable during any phase involving material manipulation that produces debris or involves potentially hazardous substances.

- Ventilation

Adequate ventilation is essential when working with adhesives, solvents, paints, or other chemical products. Inhalation of volatile organic compounds (VOCs) released by these substances can lead to respiratory irritation, dizziness, and long-term health complications. A well-ventilated workspace facilitates the dispersion of harmful fumes, reducing exposure levels. Examples include opening windows and using fans to circulate air when applying solvent-based adhesives or spray paints. A failure to provide adequate ventilation creates a hazardous environment that can compromise the well-being of the project executor.

- Hand Protection

The employment of appropriate hand protection minimizes the risk of cuts, abrasions, and chemical burns. When handling sharp materials such as glass, metal, or cutting tools, gloves serve as a physical barrier against injury. Similarly, when working with adhesives or solvents, chemical-resistant gloves prevent skin irritation or absorption of harmful substances. Selecting the appropriate type of glove for the specific task and material is crucial; for instance, heavy-duty gloves are necessary when working with sharp objects, while chemical-resistant gloves are required when handling corrosives.

- Tool Safety

Proper handling and maintenance of tools are integral to preventing accidents. Using tools according to manufacturer instructions, ensuring they are in good working order, and employing appropriate safety guards minimize the risk of injury. Examples include using a miter saw with a blade guard for accurate and safe cutting of frame components, or employing a dust collection system to mitigate airborne particulate matter. Neglecting tool safety protocols increases the likelihood of lacerations, fractures, or other serious injuries.

These considerations concerning safety practices are not optional enhancements but essential components of reflective surface frame customization. By adhering to these guidelines, project executors minimize the risk of harm, ensuring a safe and productive crafting experience. The prioritization of safety safeguards the well-being of the individual and contributes to the successful completion of a visually appealing and professionally executed project.

7. Durability

Durability, within the context of reflective surface enhancement, directly influences the long-term aesthetic and functional value of the customized piece. Factors impacting durability must be considered during material selection, construction, and finishing to ensure the creation of a resilient and enduring decorative element.

- Material Selection and Environmental Factors

The choice of materials significantly affects the longevity of the customized frame. Exposure to moisture, temperature fluctuations, and ultraviolet radiation can degrade susceptible materials, leading to warping, cracking, or discoloration. Utilizing weather-resistant woods, marine-grade adhesives, and UV-protective finishes is critical for projects located in areas prone to environmental stressors. A frame constructed with untreated softwood in a bathroom, for example, will exhibit deterioration far sooner than one built with cedar and sealed with a waterproof coating. Selecting appropriate materials extends the lifespan of the frame and minimizes the need for costly repairs or replacements.

- Joint Strength and Structural Integrity

The method of joining frame components influences overall structural stability. Weak joints are prone to failure under stress, leading to separation or collapse of the frame. Employing robust joinery techniques, such as mortise and tenon joints or biscuit joints, and utilizing high-strength adhesives enhances the structural integrity of the frame. A frame assembled with poorly aligned or weakly glued joints, in contrast, will be susceptible to loosening and eventual breakage. Reinforcing joints with metal fasteners can further augment stability, particularly for larger frames or those supporting heavy reflective surfaces.

- Surface Protection and Finish Application

The application of protective finishes shields the frame from scratches, moisture, and ultraviolet damage. A durable finish, such as a polyurethane coating or a marine varnish, creates a barrier against environmental factors, preserving the aesthetic appearance of the frame. A frame left unfinished or coated with a low-quality finish is vulnerable to stains, water damage, and fading. Applying multiple coats of a high-quality finish, sanding between coats, and ensuring proper curing contributes to a resilient and visually appealing surface. Selecting a finish compatible with the chosen frame material is crucial for achieving optimal protection and adhesion.

- Maintenance and Preventative Measures

Regular maintenance prolongs the lifespan of a customized reflective surface frame. Periodic cleaning removes dust and grime, preventing the buildup of contaminants that can degrade the finish. Applying protective waxes or polishes replenishes the surface coating and enhances resistance to scratches and moisture. Promptly addressing minor damage, such as chips or scratches, prevents further deterioration. Neglecting maintenance leads to accelerated wear and tear, necessitating more extensive repairs or eventual replacement. Implementing a routine maintenance schedule ensures the long-term preservation of the customized frame and maintains its aesthetic appeal.

In summary, prioritizing durability throughout the design and construction process ensures that customized reflective surface frames provide lasting aesthetic value and functional performance. Thoughtful material selection, robust construction techniques, effective surface protection, and regular maintenance collectively contribute to the creation of a resilient and enduring decorative element, maximizing the return on investment and minimizing the environmental impact of frequent replacements.

Frequently Asked Questions

This section addresses prevalent inquiries regarding the process of customizing reflective surface frames, providing concise and informative responses based on established practices and material science.

Question 1: What types of adhesives are most suitable for attaching decorative elements to a glass reflective surface?

Silicone-based adhesives and specialized glass adhesives are generally recommended for adhering embellishments to glass. These adhesives provide a strong, permanent bond and remain transparent upon curing, ensuring that the adhesive does not detract from the aesthetic appearance. Consider the weight of the embellishment when selecting an adhesive.

Question 2: How does one prevent wood frames from warping in high-humidity environments?

Employing hardwoods such as cedar or redwood, which possess inherent moisture resistance, can mitigate warping. Furthermore, applying a waterproof sealant, such as marine varnish or polyurethane, creates a protective barrier against moisture absorption. Consistent application and proper maintenance of the sealant are essential for long-term protection.

Question 3: What techniques ensure precise mitered corners when constructing a wooden frame?

A miter saw is the most effective tool for achieving accurate mitered corners. Precise measurements and consistent blade angles are crucial. Utilizing a clamping system during the gluing and fastening process ensures that the corners remain aligned until the adhesive has fully cured. Test-fitting the frame components prior to applying adhesive is recommended.

Question 4: How can a professional-looking paint finish be achieved on a reflective surface frame?

Proper surface preparation, including sanding and priming, is essential. Applying thin, even coats of high-quality paint with a brush, roller, or spray gun produces the most desirable results. Sanding lightly between coats ensures a smooth surface. Allowing sufficient drying time between coats and protecting the painted surface from dust or debris during the drying process is crucial.

Question 5: What safety precautions should be observed when cutting glass or tile for a mosaic frame?

Safety eyewear and gloves are mandatory to protect against flying shards and sharp edges. A dedicated glass cutter or tile nipper should be used to minimize breakage and ensure clean cuts. Working in a well-lit area allows for better visibility and reduces the risk of accidents. Dispose of broken glass and tile fragments responsibly.

Question 6: How does one prevent damage to the reflective surface while customizing the frame?

Protect the reflective surface with a drop cloth or protective film before commencing any work. Avoid applying excessive pressure to the reflective surface during frame attachment or embellishment. Use non-abrasive cleaning agents to remove any adhesive residue or fingerprints from the reflective surface. Handle the reflective surface with care to prevent scratches or cracks.

In summary, customizing reflective surface frames involves a multifaceted approach encompassing material selection, construction techniques, safety protocols, and finishing procedures. Adherence to established best practices enhances the aesthetic appeal and longevity of the customized piece.

The subsequent section will explore advanced techniques and creative applications within reflective surface frame customization, providing further insights into this craft.

Conclusion

The preceding exposition has detailed the multifaceted aspects inherent in the customization of reflective surface frames. From meticulous material selection and precise measurement to stringent adherence to safety protocols and a focused emphasis on design cohesion, the successful execution of these projects necessitates a comprehensive understanding of diverse technical and aesthetic considerations. The presented techniques and guidelines serve as a foundational resource for achieving enduring and visually compelling results.

Effective application of these principles empowers individuals to elevate interior spaces through personalized enhancements to reflective surfaces. The pursuit of reflective surface frame customization, therefore, represents a fusion of artistic expression and practical craftsmanship, yielding functional art that enriches the built environment. Continued exploration and refinement of these techniques will undoubtedly contribute to the evolution of this craft and its ongoing integration into interior design practices.