A homemade device designed to compress the limbs of a compound bow, allowing for safe and efficient maintenance, repair, or modification. This tool essentially replicates the function of commercially manufactured bow presses, enabling archers to perform tasks such as changing strings, adjusting cams, or installing peep sights without risking damage to the bow or personal injury.

The creation and utilization of such a device offers several advantages. It provides a cost-effective alternative to purchasing professional equipment, particularly for archers on a budget. Furthermore, constructing one fosters a deeper understanding of bow mechanics and promotes self-sufficiency in archery-related tasks. Historically, archers have adapted various tools and techniques to achieve limb compression, reflecting a continuous desire to maintain and customize their equipment independently.

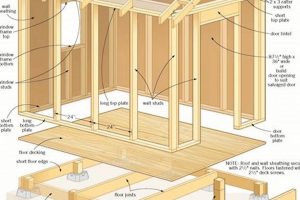

This article will explore various designs for constructing a device of this type, outlining the necessary materials, tools, and safety precautions. It will also delve into the proper techniques for using these devices to ensure safe and effective bow maintenance. Different approaches to construction will be evaluated based on factors such as cost, complexity, and compatibility with different bow models.

Essential Considerations for a Self-Made Bow Compression Tool

The creation and employment of a self-fabricated bow compression tool necessitate careful consideration of design, materials, and operational procedures to ensure both user safety and bow integrity.

Tip 1: Accurate Measurement is Paramount: Thoroughly measure the dimensions of the bow’s limbs and cam system before commencing construction. Precise measurements are critical for ensuring the tool adequately supports the bow without causing undue stress or damage.

Tip 2: Material Selection Influences Durability: Opt for high-strength materials such as steel or reinforced composites for critical load-bearing components. Inferior materials may compromise the tool’s structural integrity, leading to potential failure under load.

Tip 3: Gradual Compression Prevents Damage: Implement a system that allows for slow, controlled compression of the bow limbs. Avoid abrupt or uneven application of force, which can result in limb twisting or cracking.

Tip 4: Safety Mechanisms are Non-Negotiable: Incorporate safety features such as locking mechanisms or redundant supports to prevent accidental release of the bow limbs. Such measures mitigate the risk of projectile ejection and potential injury.

Tip 5: Consistent Monitoring During Operation is Essential: Closely observe the bow and tool during compression and decompression for any signs of stress, deformation, or slippage. Cease operation immediately if any anomalies are detected.

Tip 6: Compatibility with Bow Type Matters: Design the tool to accommodate the specific geometry and dimensions of the intended bow model. A universal design may not provide adequate support or may introduce unintended stress points.

Tip 7: Thorough Testing Prior to Live Use: Conduct rigorous testing of the tool under simulated load conditions before utilizing it on an actual bow. This allows for identification and correction of any design flaws or weaknesses.

Adhering to these principles will enhance the safety and effectiveness of a self-fabricated bow compression device, enabling archers to perform necessary maintenance and adjustments with confidence.

The subsequent sections will provide detailed construction plans and operational guidelines, further emphasizing the importance of meticulous craftsmanship and responsible usage.

1. Accurate Bow Measurements

The successful creation and utilization of a homemade bow compression device hinge critically on obtaining precise bow measurements. This stems from the fundamental requirement that the device must interface securely and uniformly with the bow’s limbs. Inaccurate measurements can lead to several detrimental outcomes, including slippage during compression, uneven pressure distribution on the limbs, and ultimately, potential damage to the bow itself. For example, if the width of the limb tips is not accurately determined, the yokes of the compression device may not provide adequate support, increasing the risk of limb twisting or complete failure under load.

The practical significance of accurate measurements extends beyond the initial construction phase. When performing tasks such as string replacement or cam adjustments, the device must maintain a consistent and stable grip on the bow. Variances in limb thickness or curvature, if unaccounted for, can introduce inconsistencies in the compression process, leading to inaccurate adjustments or premature wear on bow components. Consider a scenario where the axle-to-axle distance is miscalculated: this can result in over-compression of the limbs, potentially altering the bow’s draw length and overall performance characteristics.

In summary, accurate bow measurements are not merely a preliminary step but rather an indispensable component in the design and operation of a device of this type. Failure to prioritize precision in this area can compromise the tool’s functionality, jeopardize the bow’s integrity, and pose a safety hazard to the user. By meticulously documenting the relevant dimensions and incorporating them into the design, individuals can significantly enhance the effectiveness and safety of the overall system.

2. Material Strength is Paramount

Within the context of a self-constructed bow compression tool, the principle of “Material Strength is Paramount” dictates the overall safety and efficacy of the apparatus. A homemade device operates under significant stress when compressing the limbs of a compound bow. The choice of materials directly influences the tool’s ability to withstand these forces without deformation, fracture, or catastrophic failure. Consequently, the material’s yield strength, tensile strength, and fatigue resistance are key considerations. The utilization of substandard materials can lead to structural compromise, resulting in potential damage to the bow limbs, risk of personal injury to the operator, or both. An example of this would be using low-grade steel for the primary support arms, which could bend or break under load, negating the tool’s purpose and creating a hazardous situation.

The practical implications of this principle extend beyond mere structural integrity. Material selection also affects the long-term durability and reliability of the bow compression tool. Materials prone to corrosion or fatigue will require more frequent maintenance and eventual replacement. Consider the use of untreated wood, which, while readily available, is susceptible to moisture absorption, warping, and eventual weakening. This necessitates constant inspection and potential replace

ment of components, increasing the overall cost and inconvenience associated with the self-made device. Conversely, opting for materials such as high-carbon steel or aircraft-grade aluminum, while more expensive initially, can significantly extend the tool’s lifespan and reduce the need for frequent repairs. Proper welding techniques and reinforcement further ensure robustness.

In conclusion, material strength is not a trivial aspect but a fundamental determinant of success or failure in the creation of a bow compression tool. The correct material selection can dramatically increase operational safety and enhance longevity. The challenges involved in selecting appropriate materials often lie in balancing cost considerations with performance requirements. By meticulously evaluating material properties and prioritizing strength and durability, individuals can create a reliable and safe bow compression tool that adequately meets their needs. It is imperative to choose materials that will maintain their integrity under the considerable stress of bow limb compression, lest the outcome involve expensive damage or even serious injury.

3. Controlled Compression Essential

In the realm of self-fabricated bow compression devices, the principle of controlled compression is paramount. This necessity arises from the delicate balance between exerting sufficient force to manipulate the bow’s limbs and averting any structural compromise that could result in damage or injury. The application of force must be gradual, uniform, and monitored meticulously throughout the process. Failure to adhere to these stipulations can lead to catastrophic outcomes.

- Prevention of Limb Damage

Rapid or uneven compression can induce stress fractures or delamination within the bow limbs, particularly in composite constructions. Controlled compression ensures that stress is distributed evenly across the limb surface, minimizing the risk of structural failure. A gradual compression process allows for observation and correction of any misalignments or stress concentrations that may arise.

- Safe Manipulation of Bow Components

Tasks such as string replacement or cam adjustments necessitate the safe immobilization of the bow limbs. Controlled compression provides the stability required to perform these procedures without the risk of slippage or sudden release, which could lead to projectile discharge and subsequent injury. A controlled process also allows for precise alignment of components during reassembly.

- Preservation of Bow Tuning

Uncontrolled compression can alter the bow’s factory tuning by inducing permanent deformation or changes in limb preload. Controlled compression minimizes the potential for these alterations, ensuring that the bow retains its original performance characteristics. Gradual compression also allows for incremental adjustments, facilitating fine-tuning of the bow’s parameters.

- Operator Safety

The potential energy stored within a compressed bow represents a significant safety hazard. Uncontrolled release of this energy can result in violent recoil or projectile ejection, posing a severe risk of injury to the operator and bystanders. Controlled compression mechanisms, coupled with appropriate safety protocols, mitigate these risks by providing a predictable and manageable method for manipulating the bow’s limbs.

The ramifications of uncontrolled compression when utilizing a self-constructed bow compression tool are significant, ranging from equipment damage to personal injury. The facets outlined above collectively underscore the importance of implementing a system that allows for precise and monitored force application throughout the bow maintenance or modification process. Prioritizing controlled compression is not merely a best practice but a fundamental requirement for the safe and effective use of a “diy bow press.”

4. Safety Locking Mechanisms

Safety locking mechanisms are integral to the design and operation of any homemade bow compression device. These features serve as critical safeguards against the uncontrolled release of stored energy, a risk inherent in compressing the limbs of a compound bow. Their presence or absence significantly impacts the overall safety and reliability of the device.

- Primary Containment of Stored Energy

Safety locking mechanisms function as the primary means of containing the substantial potential energy accumulated when a bow’s limbs are compressed. Common examples include ratcheting systems, pawl-and-detent mechanisms, and threaded locking collars. These components prevent the unintended reversal of the compression process, which could result in violent recoil and projectile ejection. The absence of a robust locking system increases the likelihood of accidental release, particularly during maintenance procedures such as string replacement or cam adjustments.

- Redundancy in Safety Systems

Effective safety design often incorporates redundant locking mechanisms to mitigate the risk of a single-point failure. This involves implementing multiple independent locking features that must all fail simultaneously to allow for uncontrolled release. For instance, a system might combine a ratcheting strap with a secondary locking pin. Redundancy increases the overall reliability of the safety system and reduces the probability of human error or mechanical malfunction leading to a hazardous situation.

- Load Distribution and Stability

Safety locking mechanisms often contribute to the overall load distribution and stability of the compression device. By securely engaging with the bow’s limbs or frame, these mechanisms prevent slippage or shifting under load. This is particularly important for devices that rely on friction or clamping forces for compression. A well-designed locking system ensures that the compression force is applied uniformly and consistently, minimizing the risk of limb twisting or other forms of structural stress. This increased stability directly translates into enhanced safety and precision during maintenance procedures.

- User Interface and Ergonomics

The design of the safety locking mechanisms should prioritize ease of use and intuitive operation. Complex or cumbersome locking systems can increase the likelihood of operator error, potentially negating their intended safety benefits. The mechanisms should be readily accessible, clearly identifiable, and require minimal force to engage or disengage. Ergonomic considerations can also help reduce operator fatigue, further minimizing the risk of mistakes. In a DIY setting, this ease of use is crucial, since the operator’s familiarity with the locking system may be the only thing preventing accidental release.

In summary, safety locking mechanisms are not optional add-ons but rather essential components of a functional and secure device of this type. Their design and implementation directly influence the potential for harm during bow maintenance and modification. Proper adherence to safety principles in the design and implementation of these mechanisms is crucial for ensuring the well-being of the operator and the preservation of the bow’s integrity. Ignoring such considerations may compromise operational integrity of a ‘diy bow press’ and result in potential damage or inj

ury.

5. Consistent Monitoring is Crucial

The principle of “Consistent Monitoring is Crucial” is inextricably linked to the successful and safe employment of any self-fabricated bow compression device. Given the inherent complexities and potential risks associated with compressing the limbs of a compound bow using a device constructed outside of a controlled manufacturing environment, vigilant observation during every stage of operation is not merely recommended but mandatory. A failure to consistently monitor the device, the bow, and the compression process can precipitate catastrophic outcomes, ranging from equipment damage to severe personal injury.

The significance of continuous observation stems from several factors unique to “diy bow press” applications. The construction process often involves variations in material quality, fabrication techniques, and design tolerances compared to commercially manufactured bow presses. These variables introduce uncertainties that necessitate heightened vigilance. For example, a weld of substandard quality may exhibit subtle cracking under load, a condition that could easily go unnoticed without close inspection. Similarly, minor misalignments in the compression arms or support yokes can create uneven stress distribution on the bow limbs, potentially leading to twisting or delamination. Regular monitoring enables early detection of these issues, allowing for corrective action before irreversible damage occurs. Furthermore, the operator must be attentive to any unusual sounds or vibrations emanating from the device, as these can be indicative of impending failure. This constant vigilance is a critical component of risk mitigation.

In conclusion, the imperative for consistent monitoring is not simply a precautionary measure but a fundamental requirement for the safe and effective use of a homemade bow compression tool. The inherent variability in construction, combined with the potential for significant stored energy release, demands unwavering attention throughout the entire compression and decompression cycle. Only through diligent observation can potential problems be identified and addressed proactively, thereby minimizing the risks associated with the use of such devices. It is essential that builders and users of ‘diy bow press’ appreciate this imperative. Ignoring these critical aspects of operation will certainly increase the risk of damage or injury.

6. Bow Type Compatibility

Bow type compatibility stands as a foundational consideration in the successful design and implementation of any homemade bow compression device. The geometric and structural diversity among different compound bow models necessitates a tailored approach to ensure safe and effective operation. A compression tool designed without specific regard for the bow model’s unique characteristics can introduce undue stress, cause damage, or simply fail to function as intended.

- Limb Tip Geometry

The shape and dimensions of the limb tips vary significantly between different bow manufacturers and models. Some bows feature parallel limbs, while others exhibit more pronounced curves or reflex/deflex designs. The yokes or cradles of the compression device must conform to the specific limb tip geometry to ensure secure and uniform contact. Mismatched yokes can lead to localized stress concentrations, potentially causing limb twisting or even cracking. For example, attempting to compress a bow with highly pre-stressed limbs using a device designed for parallel limbs is almost certain to result in damage.

- Axle-to-Axle Length

Axle-to-axle (ATA) length, the distance between the bow’s axles, is a critical parameter that dictates the overall compression range required of the device. Shorter ATA bows require less compression than longer ATA bows to achieve the same degree of string relaxation. A compression tool designed for a specific ATA range may be unsuitable for bows with significantly different ATA lengths. Over-compression can damage the limbs or cams, while under-compression may prevent the operator from performing necessary maintenance tasks.

- Cam System Design

Compound bows employ various cam system designs, including single cam, dual cam, hybrid cam, and binary cam systems. The shape, size, and orientation of the cams influence the way the limbs deflect during compression. The compression device must accommodate the cam system’s geometry to prevent interference or damage. For instance, some cam systems require specific support points to prevent cam rotation during compression, a feature that may be absent in a generic compression tool. A lack of consideration here can cause cams to get out of sync, altering the bow’s timing.

- Limb Material and Construction

Bow limbs are constructed from a variety of materials, including fiberglass, carbon fiber, and laminated wood. Each material exhibits different stiffness characteristics and sensitivity to stress concentrations. The compression device must apply force in a manner that is compatible with the limb material’s properties. For example, carbon fiber limbs may be more susceptible to damage from localized pressure than fiberglass limbs. The design must ensure an even distribution of compression force to minimize the risk of material failure.

In summary, bow type compatibility is not a matter of mere convenience but a fundamental requirement for the safe and effective use of a “diy bow press”. These aspects collectively underscore the importance of tailoring the device’s design to the specific characteristics of the bow model being serviced. The absence of this consideration can lead to damage, injury, or simple inoperability, negating any potential cost savings associated with a homemade solution. One must fully evaluate these considerations when creating a functional press.

7. Thorough Prior Testing

Thorough prior testing constitutes a critical phase in the development and deployment of any self-constructed bow compression device. The inherent risks associated with compressing high-tension bow limbs, coupled with the variability of do-it-yourself construction methods, necessitate rigorous testing protocols to validate the device’s safety and functionality before live application. This testing regimen serves as a crucial safeguard against potential equipment damage or personal injury.

- Structural Integrity Validation

Prior to use, the bow press must undergo load testing exceeding its anticipated operational stresses. This involves subjecting the device to forces equivalent to or greater than those encountered during maximum bow limb compression. The testing should assess for any signs of structural deformation, weld failure, or material yielding. For example, applying a static load equivalent to 150% of the highest expected bow draw weight and holding it for a sustained period can reveal weaknesses in the frame or compression mechanisms. Such testing is vital in identifying potential points of failure before they manifest during actual use.

- Compression Mechanism Reliability

The compression mechani

sm, whether it be a threaded rod, ratchet system, or other configuration, must be tested for smooth and consistent operation across its entire range of motion. This involves repeatedly cycling the mechanism under load to identify any binding, slippage, or premature wear. For instance, if a threaded rod system is employed, the threads should be inspected for signs of stripping or galling after repeated use. A reliable compression mechanism is essential for controlled and predictable limb compression. - Safety Feature Verification

Any safety features incorporated into the design, such as locking pins, ratchet pawls, or safety straps, must be rigorously tested to ensure their proper function. This involves simulating scenarios where these features are required to prevent uncontrolled limb decompression. For example, the locking pin on a threaded rod system should be subjected to shear forces exceeding the maximum anticipated load to verify its integrity. Similarly, the ratchet pawl should be tested for its ability to hold the compression mechanism in place under load. This aspect of the testing is critical for confirming the device’s ability to mitigate the risk of accidental release.

- Bow Compatibility Assessment

The bow press must be tested with a variety of bow models representing different limb geometries and draw weights. This assessment ensures that the device is compatible with the range of bows for which it is intended and identifies any potential for interference or damage. For instance, if the bow press is designed for parallel limb bows, it should be tested with bows featuring more aggressive limb angles to ensure that the limbs are not subjected to undue stress. This testing is crucial for verifying the device’s versatility and preventing compatibility issues.

The facets of thorough prior testing collectively contribute to the development of a safer and more reliable DIY bow press. By systematically evaluating the device’s structural integrity, compression mechanism reliability, safety feature efficacy, and bow compatibility, potential weaknesses can be identified and addressed before the device is put into service. This rigorous testing regimen is paramount for minimizing the risks associated with a homemade device and ensuring the safety of both the user and the equipment being serviced. Neglecting these testing phases increases the likelihood of device failure, equipment damage, and/or personal injury when using a “diy bow press”.

Frequently Asked Questions about Constructing a DIY Bow Press

This section addresses common inquiries regarding the creation and utilization of a self-fabricated bow compression tool. The following questions aim to clarify important considerations for individuals contemplating this endeavor.

Question 1: What are the fundamental safety precautions when utilizing a DIY bow press?

Prior to any operation, ensure the bow press is stable and securely positioned. Always wear appropriate eye protection. Gradually compress the bow limbs, closely monitoring for any signs of stress or instability. Never exceed the manufacturer’s recommended draw weight. Implement a redundant safety mechanism to prevent accidental release.

Question 2: What types of materials are suitable for constructing a DIY bow press?

High-strength steel, reinforced aluminum, or durable composites are appropriate choices for load-bearing components. Wood is generally unsuitable for critical structural elements due to its inherent variability and lower tensile strength. Material selection should prioritize strength, rigidity, and resistance to corrosion.

Question 3: How can the compatibility of a DIY bow press with different bow models be ensured?

Carefully measure the limb width, limb angle, and axle-to-axle length of each bow model. Design the press with adjustable components or interchangeable adapters to accommodate variations in these parameters. Conduct thorough testing with each bow model before performing any maintenance tasks.

Question 4: What are the potential risks associated with using a poorly constructed DIY bow press?

A poorly constructed press may fail under load, resulting in damage to the bow limbs, injury to the operator, or both. Uncontrolled release of stored energy can cause projectile ejection and subsequent impact injuries. Improperly aligned compression arms can induce limb twisting or delamination.

Question 5: Is it more cost-effective to build a DIY bow press than to purchase a commercial model?

The cost-effectiveness depends on the availability of materials, tools, and fabrication skills. While a DIY press may initially appear cheaper, the cost of materials, potential rework, and the risk of damaging the bow should be factored into the equation. Commercial models offer guaranteed performance and safety features.

Question 6: What essential tools are required for constructing a DIY bow press?

Depending on the design, essential tools may include a metal saw, welding equipment, a drill press, measuring instruments (calipers, rulers, protractors), and various hand tools. Access to specialized equipment such as a lathe or milling machine may be necessary for certain designs.

These questions and answers highlight the importance of careful planning, material selection, and construction techniques when undertaking a DIY bow press project. Safety should always be the paramount consideration.

The subsequent section will delve into practical considerations for using the constructed device.

DIY Bow Press

This exploration has underscored the multifaceted nature of constructing a device of this type. The preceding sections have illuminated the critical importance of precise measurements, material selection, controlled compression, robust safety mechanisms, consistent monitoring, bow type compatibility, and thorough prior testing. Each of these elements represents a crucial link in the chain that determines the functionality and safety of a device.

The decision to pursue a self-fabricated bow compression tool should be approached with a sober assessment of one’s capabilities, resources, and understanding of archery mechanics. While the allure of cost savings and customization may be strong, the potential consequences of a poorly executed project can be severe. If proceeding, adherence to established engineering principles and meticulous execution are not merely recommended, but mandatory for the safe and effective maintenance of archery equipment.