The practice involves the independent creation of candle components, specifically focusing on the fibrous core responsible for drawing fuel to the flame. This core, when crafted in a do-it-yourself manner, allows for customization based on the type of wax used, the size of the candle container, and the desired burning characteristics. As an example, an individual may choose to braid cotton string to create a thicker, more robust component for a larger diameter candle.

The significance of this approach lies in its capacity to reduce material costs, promote sustainability through the reuse of resources, and provide enhanced control over the final product’s performance. Historically, self-sufficiency in producing essential household items was commonplace; this activity represents a contemporary resurgence of that tradition. Benefits extend to the satisfaction derived from creating a personalized item and the potential for tailoring the burn rate and fragrance throw to individual preferences.

Subsequent sections will explore the selection of appropriate materials, various techniques for construction, safety considerations, and troubleshooting common issues encountered during the fabrication process. This will enable informed decision-making and successful integration of self-made components into the broader candle-making endeavor.

Essential Guidance for Candle Core Fabrication

The subsequent directives offer crucial advice for ensuring optimal performance and safety when constructing candle cores from raw materials. Careful adherence to these principles will mitigate potential hazards and improve the overall quality of the finished candle.

Tip 1: Material Selection is Paramount: Opt for natural fibers such as cotton, hemp, or linen. Synthetic materials may not burn cleanly and can release undesirable fumes.

Tip 2: Strand Count Influences Burn Rate: A greater number of strands generally results in a faster burn. Experimentation is crucial to determine the appropriate configuration for a given wax and candle diameter.

Tip 3: Pre-Waxing Enhances Capillary Action: Prior to embedding in wax, saturate the core with the intended wax type. This promotes consistent fuel delivery to the flame.

Tip 4: Maintain Consistent Tension During Construction: Uneven tension can lead to inconsistent burning or premature extinguishing. Ensure uniform tightness when braiding or twisting the core.

Tip 5: Center the Core Precisely: Accurate centering within the candle container is vital for even wax consumption and prevention of tunneling.

Tip 6: Trim Excess Length Post-Pouring: Once the candle has cooled and solidified, trim the exposed core to approximately 1/4 inch. This facilitates clean ignition.

Tip 7: Test Burn Before Mass Production: Always conduct a test burn with a single candle to assess burn characteristics and adjust the core design as needed.

Implementing these recommendations enables a more controlled and predictable candle-making process. The investment in careful preparation and execution directly translates to a superior finished product.

The concluding section will summarize the key aspects of this process and provide recommendations for further exploration and refinement of personal techniques.

1. Fiber Type

Fiber type selection exerts a significant influence on the performance and safety of do-it-yourself candle cores. The material composition dictates burn characteristics, wax absorption rates, and the potential for harmful emissions. Therefore, informed fiber selection constitutes a critical step in the candle-making process.

- Cotton’s Versatility

Cotton stands as a frequently employed fiber due to its availability and affordability. Its absorbency facilitates wax saturation, promoting a stable flame. However, untreated cotton can produce excessive soot; therefore, pre-waxing is crucial to mitigate this issue. Different weaves, such as flat braid or coreless, influence the burn rate and structural integrity of the resulting wick.

- Hemp’s Natural Qualities

Hemp provides a natural, unbleached alternative. Its inherent strength allows for the creation of robust cores, particularly suitable for larger candles or those utilizing thicker waxes like beeswax. Hemp’s relatively slow burn rate contributes to longer-lasting candles. However, hemp can occasionally produce a more pronounced scent when burned, which may interfere with fragrance oils.

- Linen’s Sturdy Construction

Linen offers a rigid structure, making it suitable for cores requiring enhanced stability. Its resistance to fraying simplifies the manufacturing process. Similar to hemp, linen may possess a slight natural aroma that should be considered when formulating scented candles. Proper pre-treatment with wax is essential to ensure consistent burning performance.

- Synthetic Fiber Avoidance

The utilization of synthetic fibers (e.g., nylon, polyester) is strongly discouraged. These materials often melt rather than burn cleanly, potentially releasing toxic fumes and compromising the structural integrity of the candle. Their limited absorbency hinders wax saturation, resulting in uneven burning and premature extinguishing. Adherence to natural fiber alternatives is paramount for safety and performance.

In conclusion, the selection of fiber type directly impacts the functionality and safety of homemade candle cores. Careful consideration of material properties, including absorbency, burn rate, and potential emissions, ensures the creation of high-quality candles that meet desired performance characteristics. Natural fibers like cotton, hemp, and linen offer viable options, while synthetic materials should be strictly avoided due to inherent safety concerns and performance limitations.

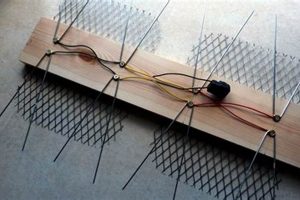

2. Braid Structure

Braid structure, in the context of crafting fibrous cores for candles via do-it-yourself methods, exerts a direct influence on the capillary action and burning characteristics of the finished product. The arrangement of individual strands within the core dictates the rate at which molten wax is drawn upwards to fuel the flame. A looser braid, for example, allows for increased wax absorption but may also lead to a faster, less controlled burn. Conversely, a tighter braid restricts wax flow, potentially causing the candle to tunnel or extinguish prematurely. The specific pattern employed whether a flat braid, a square braid, or a spiral twist each imparts distinct burning properties. For instance, flat braided cores often exhibit a self-trimming quality due to the way the outer fibers are exposed to the flame, while coreless braids, lacking a central support, tend to curl as they burn, mitigating carbon buildup.

The implications of braid structure extend to the compatibility of the core with differ

ent wax types. Softer waxes, such as soy wax, generally require a tighter braid to prevent excessive fuel delivery and smoking. Harder waxes, like beeswax or paraffin, may necessitate a looser braid to ensure sufficient wax absorption and sustained burning. An individual engaged in do-it-yourself candle core fabrication might experiment with various braid structures to optimize performance based on the chosen wax and the diameter of the candle container. Failure to adequately consider braid structure can result in uneven burning, excessive smoking, or premature extinguishing, rendering the candle unusable.

In summary, braid structure is a critical parameter in the do-it-yourself fabrication of candle cores. Understanding the relationship between strand arrangement, wax absorption, and burning characteristics allows for the creation of customized cores that are tailored to specific candle-making needs. Optimization of braid structure, through careful selection and experimentation, contributes to improved candle performance, enhanced safety, and the overall quality of the finished product. Overlooking this aspect introduces significant challenges in achieving a consistent and satisfactory burn.

3. Wax Absorption

Wax absorption constitutes a fundamental aspect of effective fibrous cores, particularly when such components are created through do-it-yourself methods. This characteristic defines the capacity of the core to draw molten wax upwards via capillary action, thus providing a continuous fuel source to the flame. Insufficient wax absorption leads to a weak or nonexistent flame, while excessive absorption results in smoking, dripping, and a rapid burn rate. Consequently, the ability to control and optimize wax absorption is paramount in achieving consistent and predictable candle performance.

The type of material and the structure of the core directly influence wax absorption. Natural fibers, such as cotton, hemp, and linen, possess inherent absorbent properties due to their cellular structure. Pre-treating the core with melted wax of the type intended for the candle further enhances absorption, priming the material for consistent fuel delivery. A tightly braided or twisted core restricts wax flow, while a loosely constructed core allows for greater, but potentially uncontrolled, absorption. The diameter of the core must also be proportionate to the candle’s size and the wax’s melting point. A thin core in a large-diameter candle will struggle to draw sufficient wax, whereas a thick core in a small candle will cause it to burn too quickly. In practice, a craftsperson making do-it-yourself candles must experiment with varying core thicknesses, braid structures, and pre-treatment methods to find the optimal combination for their specific wax and candle container. Test burning is essential to assess the absorption rate and adjust the core design as needed.

In summary, the degree of wax absorption directly dictates the burning characteristics of the candle. By carefully selecting materials, manipulating core structure, and implementing appropriate pre-treatment techniques, individuals engaged in creating components themselves can effectively manage wax absorption to achieve desired burn times, flame stability, and overall candle quality. Understanding and controlling this aspect is key to successful execution and mitigates common issues associated with homemade candles, such as tunneling, smoking, and inconsistent burning.

4. Core Diameter

Core diameter, in the context of constructing components for candles independently, represents a critical parameter governing fuel delivery and burn characteristics. The diameter, measured in units appropriate for the scale of the task, dictates the volume of molten wax that can be drawn upward to sustain the flame. An undersized diameter restricts the wax supply, potentially leading to tunneling, incomplete combustion, and eventual flame extinguishment. Conversely, an oversized diameter facilitates excessive fuel delivery, resulting in smoking, dripping wax, and a drastically shortened burn time. As an example, a small tealight candle utilizing paraffin wax requires a significantly smaller diameter than a large pillar candle made from beeswax.

The selection of an appropriate core diameter necessitates a nuanced understanding of the interplay between wax type, candle diameter, and desired burn profile. Softer waxes, such as soy wax, often require a larger diameter to maintain adequate fuel flow due to their lower melting points and higher viscosity. Harder waxes, like beeswax, may necessitate a smaller diameter to prevent over-fueling and subsequent smoking. Furthermore, the diameter of the candle container influences the optimal core diameter; wider candles require larger diameters to ensure even wax pool formation and prevent the candle from burning down the center, leaving substantial wax residue on the sides. For instance, a mason jar candle with a diameter of four inches typically benefits from a significantly thicker core compared to a votive candle with a diameter of two inches.

In summary, core diameter is a key determinant of candle performance and safety within the realm of self-made candle cores. Proper selection, informed by wax properties, candle dimensions, and desired burn characteristics, is essential for achieving a clean, consistent, and long-lasting flame. Challenges in achieving the correct diameter often stem from a lack of empirical testing and insufficient consideration of the complex interaction between core diameter, wax type, and candle size. Careful experimentation and meticulous record-keeping are crucial for developing reliable diameter guidelines for various candle-making scenarios.

5. Burn Consistency

Burn consistency, the uniform and predictable consumption of wax and the sustained production of a stable flame, represents a primary objective in the craft of candle making. When individuals engage in the do-it-yourself creation of candle cores, achieving consistent burn characteristics becomes a direct measure of success. Variations in fiber type, braid structure, core diameter, and wax absorption all influence how a candle burns. For example, a core constructed with uneven tension may exhibit flickering, smoking, or premature extinguishing, while a properly constructed core yields a steady flame and even wax pool. The relationship, therefore, is causal: the quality of the core directly impacts the consistency of the burn. Burn consistency is not merely an aesthetic concern; it affects the candle’s longevity, fragrance throw, and, most importantly, its safety. Uneven burning can lead to wax spillage and potential fire hazards.

The practical significance of understanding this connection is exemplified in the iterative process of candle development. An artisan might start with a standard cotton core, observe the burn characteristics, and then adjust the braid tightness to reduce smoking or increase the diameter to prevent tunneling. Precise measurements and careful documentation are essential to replicate successful core designs. Commercial candle manufacturers employ sophisticated testing methodologies to ensure burn consistency across entire production runs. While the individual maker may not have access to the same resources, a commitment to careful observation and meticu

lous record-keeping can achieve comparable results. For instance, a specific blend of soy and beeswax may require a core with a tighter braid and pre-treatment with beeswax to achieve optimal burn consistency.

In conclusion, burn consistency is inextricably linked to the art and science of creating candle cores independently. The ability to manipulate core characteristics to achieve a predictable and safe burn represents a fundamental skill. While challenges exist in replicating the precision of large-scale manufacturing, a systematic approach to material selection, core construction, and empirical testing allows individuals to produce handmade candles that rival commercially available products in terms of burn quality and safety. The commitment to achieving burn consistency ultimately elevates the craft from a simple hobby to a refined and satisfying endeavor.

6. Safety Precautions

The fabrication of fibrous candle cores via do-it-yourself methods necessitates strict adherence to safety precautions to mitigate potential hazards. The absence of standardized manufacturing processes introduces variability in material quality and construction techniques, thereby increasing the risk of unsafe burning characteristics. Ignition of flammable materials in the vicinity, burns from molten wax, and the release of toxic fumes from improper material selection represent plausible dangers. Consequently, implementation of comprehensive safety protocols is not merely advisable but fundamentally essential to the responsible practice of creating candle cores independently. Failure to prioritize safety introduces significant risks, potentially resulting in property damage, personal injury, or health complications. For example, using synthetic fibers instead of natural ones can release harmful toxins when burned.

One critical precaution involves ventilation. The process of melting wax and burning experimental cores can generate airborne particles and volatile organic compounds. Ensuring adequate airflow through open windows or the use of a ventilation system reduces the concentration of these potentially harmful substances. Another essential practice concerns the proper handling of molten wax. Maintaining a safe distance from heat sources, using appropriate protective gear such as gloves and eye protection, and having a readily available fire extinguisher are vital steps. Furthermore, the selection of appropriate core materials is paramount. Natural fibers such as cotton, hemp, and linen are generally safer alternatives to synthetic materials, which can melt or release toxic fumes. It is crucial to test burn each core design in a controlled environment before incorporating it into a finished candle. For instance, pre-treating the core with borax can improve its burning characteristics and reduce the risk of excessive smoking, but handling borax requires caution and proper disposal methods.

In summary, the intersection of safety precautions and the do-it-yourself creation of candle cores is a matter of paramount importance. By acknowledging the inherent risks associated with unregulated material selection and construction processes, and by implementing comprehensive safety protocols, individuals can significantly reduce the potential for accidents and adverse health effects. The challenges lie in maintaining diligence and awareness throughout the entire fabrication process and continuously seeking information to improve safety practices. The responsible creation of candle cores necessitates a proactive approach to safety, prioritizing the well-being of both the crafter and the end-user.

7. Container Compatibility

The selection of an appropriate container exerts a demonstrable influence on the efficacy of candle cores crafted through do-it-yourself methods. Container dimensions, material composition, and thermal properties directly impact the burning characteristics of a candle, necessitating careful consideration of these factors when selecting or fabricating a core. A container with a wide diameter requires a core capable of delivering a greater volume of molten wax to sustain the flame across the broader surface area. Conversely, a narrow container necessitates a smaller core to prevent over-fueling and subsequent smoking. For instance, a large mason jar intended for a soy wax candle demands a thicker, multi-strand core compared to a small tin designed for beeswax, which performs optimally with a thinner, single-strand core.

The thermal conductivity of the container material also plays a crucial role. Glass containers, commonly used in candle making, exhibit relatively low thermal conductivity, resulting in localized heating around the core. This phenomenon can lead to tunneling, where the wax burns down the center, leaving a ring of un-melted wax along the container walls. To mitigate this, a core with a larger diameter may be necessary to promote more even melting across the entire surface. Metal containers, conversely, exhibit higher thermal conductivity, facilitating more uniform wax melting. In such cases, a smaller diameter may be sufficient. Furthermore, the shape of the container influences air circulation around the flame, affecting combustion efficiency. Tall, narrow containers may restrict airflow, requiring a core that burns hotter to maintain a stable flame. Practical application involves meticulous testing of various core sizes and configurations within different container types to determine the optimal combination for achieving a consistent and even burn.

In summary, container compatibility is a non-negligible factor in achieving optimal candle performance when crafting cores independently. The container’s dimensions, material, and shape dictate the necessary core diameter and material composition to ensure consistent wax pool formation, prevent tunneling or smoking, and maximize burn time. Failure to adequately consider container characteristics can lead to suboptimal burning performance, rendering the candle aesthetically unappealing and potentially unsafe. Successful implementation requires an understanding of heat transfer principles, empirical testing, and meticulous record-keeping to establish reliable core-container pairings.

Frequently Asked Questions Regarding Wicks for Candles DIY

This section addresses common inquiries concerning the independent creation of components designed to sustain combustion in wax-based illumination devices. These questions are designed to clarify best practices and mitigate potential safety hazards.

Question 1: What are the primary advantages of constructing candle cores independently rather than purchasing pre-made versions?

Independent construction permits customization based on wax type, fragrance load, and container dimensions. It may also offer cost savings and allows for the use of specific, ethically sourced materials.

Question 2: Which natural fibers are most suitable for creating reliable fibrous candle components?

Cotton, hemp, and linen are generally considered appropriate choices. Each possesses unique absorbency and burn characteristics that influence the candle’s performance.

Question 3: Is there a specific method for determining the optimal core diameter for a given candle?

Optimal diameter is contingent upon container size, wax type, and desired burn time. Empirical testing is essential. Start with a diameter slightly smaller than anticipated and incrementa

lly increase until a consistent burn pool is achieved.

Question 4: What safety precautions should be observed when melting wax for core pre-treatment?

Wax should be melted in a double boiler to prevent overheating and potential ignition. Adequate ventilation is necessary to minimize inhalation of fumes. Appropriate personal protective equipment, including gloves and eye protection, should be worn.

Question 5: How does braid structure affect the overall burning characteristics of a candle?

Tighter braids tend to restrict wax flow, resulting in a slower burn and potentially minimizing smoking. Looser braids allow for greater wax absorption, which can lead to a faster burn and increased soot production. Experimentation is crucial.

Question 6: What are the potential consequences of using synthetic materials in candle core construction?

Synthetic materials may not burn cleanly and can release toxic fumes. They may also melt rather than burn, posing a fire hazard and compromising the candle’s structural integrity. Natural fibers are strongly recommended.

In summary, successful fabrication relies on informed material selection, meticulous construction techniques, and a commitment to rigorous testing. Adherence to safety protocols is paramount to minimizing risks and ensuring a reliable and enjoyable candle-burning experience.

The next section will delve into specific troubleshooting techniques for addressing common issues encountered during the fabrication process.

Concluding Remarks on wicks for candles diy

The preceding analysis has demonstrated the multifaceted nature of crafting candle cores independently. The successful execution of “wicks for candles diy” requires careful consideration of fiber selection, braid structure, diameter calibration, wax absorption, burn consistency, safety precautions, and container compatibility. Mastery of these elements directly correlates with the production of safe, aesthetically pleasing, and functionally reliable candles. The information presented serves as a foundational guide for practitioners seeking to refine their craft and minimize potential hazards.

Further exploration into advanced techniques, such as incorporating additives to modify burn characteristics or experimenting with alternative fiber blends, is encouraged. However, it is imperative that any deviation from established safety protocols be undertaken with extreme caution and thorough risk assessment. The pursuit of innovation must not compromise the fundamental principles of safe candle making. The long-term viability of self-made “wicks for candles diy” rests on a commitment to knowledge, diligence, and responsible experimentation.