These collections of components, accompanied by instructions, facilitate the construction of a specific structure or object by the end-user. For instance, a miniature house, a bird feeder, or a simple robot can be assembled from pre-cut materials and included hardware. The kits provide a structured approach to building, suitable for various skill levels.

The appeal of such offerings lies in several factors. They promote hands-on learning, encouraging spatial reasoning and problem-solving skills. Furthermore, completing a construction project provides a sense of accomplishment and can foster creativity. Historically, similar approaches to construction have been used in education and recreation, evolving from basic model-making to more sophisticated engineering challenges.

The subsequent discussion will address the various types of available options, considerations for choosing an appropriate set, and the value derived from engaging in such activities.

Construction Project Guidance

The following offers practical advice for selecting and utilizing structured construction materials.

Tip 1: Assess Skill Level. Determine the appropriate complexity of the project based on experience. Starting with simpler models fosters confidence and foundational skills.

Tip 2: Review Included Components. Prior to beginning assembly, carefully inventory all provided materials against the listed contents to ensure completeness and familiarity.

Tip 3: Adhere to Instruction Sequence. Follow the provided step-by-step instructions meticulously. Deviations may lead to structural instability or aesthetic imperfections.

Tip 4: Utilize Appropriate Tools. Gather necessary tools, such as screwdrivers, pliers, or adhesives, beforehand. Using the correct tools ensures a secure and professional finish.

Tip 5: Provide Adequate Workspace. Establish a clean and well-lit workspace. Sufficient space minimizes clutter and potential errors during the construction process.

Tip 6: Focus on Precision. Pay close attention to detail, ensuring proper alignment and secure connections. Accuracy is crucial for the structural integrity and appearance of the final product.

Diligent adherence to these suggestions enhances the likelihood of a successful and rewarding construction experience. Focusing on preparation and precision yields optimal results and promotes a deeper understanding of structural principles.

The subsequent sections will provide details about selection of a ‘diy building kits’.

1. Materials

The selection of construction components exerts a significant influence on the resultant item’s longevity, aesthetic qualities, and ease of assembly. The physical characteristics of the materials directly impact the structural integrity and overall appeal of the finished construction. For example, using untreated softwood for an exterior structure construction risks premature decay and structural failure, whereas employing treated lumber or composite materials enhances resistance to environmental factors. Similarly, the choice between plastic and metal for a model airplane influences both its weight and perceived realism. Component selection dictates the tools and skills required for successful assembly, influencing the overall user experience.

Consider the practical application of a birdhouse. If constructed from thin, easily cracked wood, the structure will likely be susceptible to damage from weather and animals. In contrast, a birdhouse constructed from thicker, weather-resistant cedar will provide a more durable and secure shelter. The selection of fasteners, such as screws versus nails, further impacts the construction’s stability and resistance to disassembly. The type of adhesive used, if applicable, influences the strength of bonded joints and the project’s overall resistance to stress.

In summary, careful material consideration is paramount in construction. It directly influences the durability, aesthetic value, and the ultimate success of the project. Failure to select suitable components may lead to premature failure or an unsatisfactory construction experience, underscoring the necessity of prioritizing component quality and appropriateness.

2. Complexity

Complexity represents a critical factor in the design and selection of do-it-yourself construction offerings. It dictates the target audience, required skill set, and ultimate satisfaction derived from the assembly process. A mismatch between the project’s difficulty and the user’s experience level can lead to frustration and project abandonment. Therefore, a thorough understanding of this parameter is essential for both consumers and manufacturers.

- Number of Components

The quantity of individual parts directly contributes to a project’s intricacy. A smaller parts count generally indicates a simpler design, suitable for beginners. Conversely, a high number of pieces suggests a more intricate and time-consuming assembly, demanding greater attention to detail. For example, a basic birdhouse may consist of only a few pre-cut wood panels and fasteners, while a model ship can involve hundreds of precisely crafted components.

- Instruction Detail

The clarity and comprehensiveness of the provided assembly instructions are paramount. Simple projects often feature illustrated, step-by-step guides, while more complex builds may require detailed diagrams, exploded views, and even supplementary online resources. Inadequate or ambiguous instructions can significantly increase the perceived difficulty and lead to errors during construction.

- Specialized Tools Required

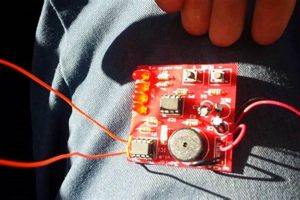

The need for specialized tools beyond common household implements also influences overall project difficulty. Projects requiring precision cutting tools, soldering equipment, or specific adhesives are inherently more challenging and demand greater technical proficiency. A simple woodworking project may only necessitate a screwdriver and hammer, whereas an electronics build could require a multimeter and soldering iron.

- Precision of Fit

The dimensional accuracy and tolerance of individual components significantly affect ease of assembly. Parts that fit together snugly and require minimal adjustment contribute to a smoother and more satisfying experience. Conversely, components with poor tolerances may necessitate significant filing, sanding, or other modifications, increasing project complexity and demanding advanced skills.

In conclusion, complexity encompasses multiple factors influencing the accessibility and enjoyment of DIY construction projects. Manufacturers must carefully consider these variables when designing kits, ensuring an appropriate level of challenge for the intended audience. Consumers should carefully assess their skill set and project requirements before selecting a kit to ensure a positive

and rewarding construction experience.

3. Instructions

Instructions represent a fundamental component of construction products, directly influencing user experience and project outcome. The completeness, clarity, and accuracy of instructions are paramount to successful assembly. Without comprehensible guidance, even a well-designed set of components becomes unusable. Instructions bridge the gap between raw materials and a finished product. Their absence or inadequacy constitutes a critical failure, leading to frustration, project abandonment, and potential safety hazards. The quality of instructions, therefore, directly correlates with product value and customer satisfaction.

Consider, for example, a model airplane. Even with precisely molded plastic components, an unclear instruction manual depicting incorrect assembly sequences or missing crucial steps will render the plane unbuildable for the average consumer. Conversely, a construction of a complex wooden puzzle benefits from detailed diagrams, numbered steps, and clear explanations of interlocking mechanisms, significantly increasing the likelihood of successful completion. The application extends beyond simple models to larger-scale projects, such as furniture construction. Vague or missing instructions regarding hardware placement or joint connections can compromise structural integrity, resulting in an unstable or unsafe finished product. Instructions detailing safety precautions are equally vital, especially when involving tools or potentially hazardous materials.

In conclusion, instructions are an indispensable element of construction products. Their quality determines project success, user satisfaction, and safety. Manufacturers must prioritize the development of clear, accurate, and comprehensive instruction manuals to ensure a positive and rewarding experience for consumers. The relationship between instructions and the kits is symbiotic; one cannot function effectively without the other.

4. Tools

The successful completion of structures relies heavily on the appropriate application of implements. Their selection and use are integral to assembling components and achieving desired outcomes. A deficiency in tools or a lack of proficiency in their utilization can impede the assembly process and compromise the structural integrity of the completed item. The relationship between the two is symbiotic, with one enabling the other.

- Fastening Implements

Screwdrivers, hammers, and wrenches are critical for securing connections between structural elements. The correct selection of a screwdriver, for example, ensures proper torque application, preventing damage to screw heads and ensuring a secure hold. Hammers, when used with appropriate force and precision, facilitate the driving of nails or staples into joining materials. Wrenches provide leverage for tightening nuts and bolts, crucial in constructions requiring robust mechanical connections. The absence of the proper fastening implements can lead to unstable joints and compromised structural integrity.

- Cutting and Shaping Instruments

Knives, saws, and chisels enable precise shaping and modification of components. Knives serve for tasks requiring delicate cuts, such as trimming excess material or scoring surfaces. Saws, whether manual or powered, allow for accurate cutting of wood, plastic, or metal to specified dimensions. Chisels facilitate the removal of material for creating joints or shaping decorative elements. Proficiency in using cutting instruments minimizes material waste and ensures accurate component dimensions, essential for proper fit and alignment.

- Measuring and Marking Devices

Rulers, measuring tapes, and squares enable accurate dimensioning and alignment. Precise measurements ensure that components are cut and positioned correctly, contributing to the overall symmetry and structural stability of the construction. Squares guarantee right angles in corners and joints, crucial for constructing structurally sound and aesthetically pleasing items. Inaccurate measurements can result in misalignment, dimensional errors, and compromised structural integrity.

- Adhesive Application Tools

Glue guns, brushes, and applicators facilitate the bonding of components. Glue guns provide controlled application of hot melt adhesives for rapid bonding. Brushes are suitable for applying liquid adhesives evenly across surfaces. Applicators enable precise placement of adhesive in hard-to-reach areas. The proper selection and use of adhesive application tools ensure strong and durable bonds between components, crucial for structures relying on adhesive joining.

The accessibility and appropriate application of tools are intrinsically linked to the success of constructing with components. The provision of necessary implements, coupled with clear instructions on their proper use, enhances the likelihood of a positive construction experience and the creation of structurally sound and aesthetically pleasing products. Tool selection should align with the complexity of the project and the skill level of the user to maximize the probability of a successful outcome.

5. Scale

Scale, in the context of modular construction packages, fundamentally influences project scope, resource requirements, and intended function. The dimensional characteristics of the components directly impact the final product’s complexity, cost, and applicability. Understanding scale is crucial for selecting an appropriate package aligned with user skill and project goals.

- Miniature Scale

Representing projects with greatly reduced dimensions, miniature scale offerings prioritize detail and aesthetic representation. Examples include model trains, dollhouses, and architectural mock-ups. These often employ intricate components and require precision assembly. Implications involve a focus on visual fidelity over structural integrity, targeting hobbyists and collectors.

- Model Scale

Model scale items strike a balance between detail and functionality, representing scaled-down versions of real-world objects or structures. Examples include model airplanes, cars, and robots. These packages often incorporate moving parts or electronic components. Implications involve educational applications, allowing users to explore mechanical principles and engineering concepts.

- Functional Scale

Functional scale structures prioritize practical utility over precise replication. Examples include furniture, garden sheds, and playhouses. These packages typically utilize larger, more robust components and emphasize ease of assembly. Implications involve providing cost-effective solutions for everyday needs, empowering users to construct usable structures with minimal specialized skills.

- Architectural Scale

Architectural scale packages focus on replicating building designs or components at a smaller yet detailed level, suitable for demonstration or planning purposes. Examples might include scaled-down versions of houses or building facades. These require significant precision and understanding of architectural concepts. The implication here is more for prof

essional use or advanced hobbyists with a deep interest in architecture.

The selection of a package must consider its scale relative to the user’s experience, available space, and intended purpose. Whether creating a detailed miniature diorama or a functional garden structure, understanding the dimensional implications ensures a satisfying and successful construction experience. The dimensional characteristics influence not only the final product but also the resources, tools, and time required for completion.

6. Purpose

The intended function of a construction project fundamentally dictates design, material selection, and assembly methods. The purpose, in essence, acts as the guiding principle throughout the entire creation process. Failure to clearly define the intended utilization of the assembled product results in a misaligned project, potentially rendering the final construction ineffective or unsuitable for its intended environment. For example, a birdhouse built for aesthetic appeal may lack essential features, such as proper drainage or predator protection, thereby failing to serve its primary function of providing a safe and habitable shelter for birds.

Consider also the contrast between educational models and functional prototypes. Educational projects often prioritize simplified assembly and visual representation of underlying principles, potentially sacrificing durability and precision. In contrast, functional prototypes demand robust construction and accurate performance to validate design concepts and withstand real-world testing. A model bridge designed to illustrate structural mechanics, for instance, may utilize lightweight materials and simplified joint connections. However, a bridge designed to bear vehicular traffic requires load-bearing materials and structurally sound connections, reflecting the distinct design considerations driven by its intended use.

In summary, the purpose serves as a critical determinant in constructing with components. It drives every design decision, from component selection to assembly techniques. A clear and well-defined purpose ensures that the assembled item fulfills its intended function effectively and reliably. Neglecting this crucial element risks creating a product that is aesthetically pleasing but functionally deficient, underscoring the importance of aligning design with intended use.

Frequently Asked Questions

The following addresses common inquiries regarding structured construction sets, providing clarity on aspects relevant to both selection and utilization.

Question 1: Are specialized tools always required for construction sets?

The necessity for specialized tools varies depending on the complexity and intended scale of the project. Simpler constructions often require only basic implements, such as screwdrivers or pliers. More intricate projects may necessitate specialized cutting, shaping, or measuring instruments.

Question 2: How is the complexity level of a construction determined?

Complexity is assessed based on the number of components, the intricacy of assembly instructions, the precision of fit required, and the need for specialized tools. Kits with a high component count and detailed instructions typically demand greater attention to detail and a higher skill level.

Question 3: What factors contribute to the quality of included instructions?

High-quality instructions are characterized by clarity, accuracy, and comprehensiveness. They feature step-by-step diagrams, numbered sequences, and clear explanations of assembly techniques. The presence of safety precautions is also essential.

Question 4: How does material selection influence the longevity of the finished product?

The choice of materials significantly impacts the durability and resistance of the completed construction to environmental factors and physical stress. Weather-resistant materials are crucial for outdoor constructions, while robust materials are essential for items intended for heavy use.

Question 5: What considerations are pertinent when selecting a set based on scale?

Scale dictates project scope, resource requirements, and intended function. Miniature scale constructions prioritize detail, while functional scale constructions emphasize utility. The selection should align with available space, user skill, and project goals.

Question 6: Why is defining the intended purpose of a construction important?

A clearly defined purpose guides design decisions, component selection, and assembly methods. The intended function of the assembled item should dictate its structural integrity, material composition, and overall design.

The above represents core inquiries concerning construction projects. Careful consideration of these facets enhances the probability of successful project completion.

The next section presents a summary of previously outlined principles.

Conclusion

The preceding exploration has outlined key elements inherent in `diy building kits`. Emphasis was placed on material selection, complexity, instruction clarity, tool requirements, dimensional scale, and, most importantly, the intended purpose of the final assembled item. Each aspect warrants careful consideration to ensure project success and user satisfaction. From miniature models to functional structures, the principles outlined serve as a foundation for both manufacturers and consumers.

The continued development and refinement of structured construction sets offer opportunities for enhanced educational experiences, creative expression, and practical problem-solving. The value derived from these activities extends beyond mere assembly, fostering critical thinking and spatial reasoning skills. It is crucial to approach selection and utilization with a discerning eye, aligning project scope with individual capabilities to maximize the benefits derived from engaging with `diy building kits`.