A collection of components and instructions designed to enable individuals to construct a functional or decorative item is prevalent in various sectors. For instance, a model airplane packaged with pre-cut wood, adhesive, and blueprints allows hobbyists to assemble the aircraft. This type of offering empowers users to engage in hands-on creation.

The advantages of such provisions include cost-effectiveness compared to pre-assembled products and the acquisition of new skills. Historically, these sets fostered creativity and problem-solving abilities. They also offer a sense of accomplishment upon completion of the project, contributing to personal enrichment and potentially stimulating entrepreneurial pursuits.

The following sections will delve into the specific applications and considerations associated with choosing and utilizing these types of resources across diverse fields, highlighting aspects like material selection, complexity levels, and safety protocols.

Optimizing the Selection and Utilization of Component-Based Construction Sets

The subsequent guidelines provide valuable insights into maximizing the experience and outcomes associated with purchasing and engaging with component-based construction sets across varied applications.

Tip 1: Assess Project Complexity. Before acquiring a set, carefully evaluate the skill level required for successful completion. Beginners should opt for simplified designs with comprehensive instructions to avoid frustration. Experienced individuals may seek more intricate projects to challenge their capabilities.

Tip 2: Scrutinize Component Quality. Examine the materials and manufacturing processes used in the production of the included components. Higher quality materials generally lead to a more durable and aesthetically pleasing finished product. Read reviews and compare different brands to assess overall quality.

Tip 3: Review Instruction Clarity. A well-structured and easily understandable instruction manual is crucial. Look for sets with clear diagrams, step-by-step guides, and readily accessible troubleshooting information. Online resources or video tutorials can be a valuable supplement.

Tip 4: Consider Required Tools. Determine if specialized tools are necessary for assembly and ensure availability prior to commencing the project. Lacking the proper tools can impede progress and potentially damage components.

Tip 5: Prioritize Safety. Always adhere to the safety guidelines provided with the set. Utilize appropriate safety equipment, such as eye protection or gloves, when necessary. Supervise children closely when they are working with these sets.

Tip 6: Plan Workspace Appropriately. Allocate a dedicated workspace that is well-lit and free from distractions. Organize components systematically to minimize the risk of loss or damage.

Tip 7: Inspect for Missing Parts. Upon opening the package, verify that all components listed in the inventory are present. Contact the manufacturer immediately if any parts are missing to ensure project completion.

Key takeaways from these recommendations include the importance of careful planning, meticulous execution, and a commitment to safety. By adhering to these principles, individuals can significantly enhance their experience and achieve superior results with component-based construction sets.

The concluding section will summarize the broader implications of utilizing these sets and offer perspectives on their role in promoting creativity and skill development.

1. Assembly instructions

The assembly instructions are an indispensable component of any component-based construction set. Their clarity and comprehensiveness directly influence the user’s ability to successfully complete the project. Poorly written or ambiguous instructions can lead to frustration, errors, and ultimately, project failure. Consider, for example, a complex electronic project; without precise schematics and step-by-step guidance, the likelihood of correctly assembling the circuit board is minimal. Conversely, well-structured instructions, often including diagrams or video demonstrations, empower users to navigate even intricate projects with confidence.

The effectiveness of assembly instructions extends beyond mere clarity. The level of detail provided, the inclusion of troubleshooting tips, and the organization of information all contribute to the user experience. Many manufacturers now incorporate augmented reality features into their instructions, overlaying digital guidance onto the physical components, thereby further simplifying the assembly process. A practical application of well-designed instructions can be observed in furniture assembly. Clear, concise instructions minimize assembly time and reduce the potential for errors, resulting in a functional and aesthetically pleasing piece of furniture.

In summary, the quality of assembly instructions is paramount to the success of any component-based construction set. They serve as the critical link between the components and the desired outcome. Challenges arise when instructions are translated poorly or when they assume a certain level of prior knowledge. However, by prioritizing clear, comprehensive, and user-friendly instructions, manufacturers can significantly enhance the user experience and ensure the successful completion of projects. This understanding is crucial for both manufacturers in developing quality kits and for consumers in selecting them.

2. Component Quality

The overall success and longevity of any component-based construction set is inextricably linked to the quality of the individual components included. Inferior materials or poorly manufactured parts can compromise the integrity of the final product, leading to functional failures, aesthetic deficiencies, and ultimately, user dissatisfaction.

- Material Durability and Longevity

The intrinsic properties of the materials used in component construction directly impact the product’s lifespan. For example, electronic component sets utilizing low-grade resistors or capacitors may experience premature failure due to overheating or degradation. Similarly, in woodworking sets, the use of soft or knotty lumber can result in structural weakness and difficulty in assembly. High-quality materials, conversely, ensure the product’s resilience over time.

- Manufacturing Precision and Tolerances

The accuracy of component dimensions and the adherence to specified tolerances are critical for seamless integration and proper functionality. A model airplane kit with poorly cut wing components may exhibit aerodynamic instability. Mechanical kits containing gears or bearings with excessive tolerances can suffer from reduced efficiency and increased wear. Precise manufacturing promotes ease of assembly and optimized performance.

- Material Compatibility and Interactions

strong>

Ensuring the compatibility of different materials within a set is essential to prevent adverse interactions. For instance, using incompatible adhesives on certain plastics can cause degradation or bonding failure. In electrical kits, utilizing improperly insulated wiring can lead to short circuits or electrical hazards. Careful material selection mitigates the risk of such issues.

- Surface Finish and Aesthetic Appeal

The quality of the surface finish contributes significantly to the aesthetic appeal and overall perceived value of the completed project. A poorly finished wooden component may exhibit splinters or an uneven surface, detracting from its visual presentation. Similarly, in plastic model kits, the presence of flash or molding imperfections diminishes the overall appearance. A refined surface finish enhances the aesthetic qualities of the product.

The considerations outlined above demonstrate the multi-faceted impact of component quality on component-based construction sets. The integration of high-grade materials and meticulous manufacturing processes is paramount for ensuring both the functional integrity and the aesthetic value of the finished product. Manufacturers must prioritize component quality to deliver a positive and rewarding experience for end-users.

3. Skill level

The selection of a component-based construction set should align directly with the user’s existing skill level. This correlation is paramount, influencing both the enjoyment derived from the process and the likelihood of successful project completion. A mismatch between the complexity of the set and the user’s capabilities can lead to frustration, demotivation, and project abandonment. For instance, presenting a novice woodworker with a complex furniture-making kit requiring advanced joinery techniques is likely to yield unsatisfactory results. Conversely, an experienced electronics hobbyist may find a rudimentary circuit-building set unstimulating and lacking in intellectual engagement. Therefore, an accurate assessment of one’s proficiency is critical to optimizing the learning and creative experience.

Practical significance of understanding this connection lies in its potential impact on learning and skill development. A well-chosen set, appropriately challenging yet achievable, provides an ideal platform for honing existing skills and acquiring new ones. For example, a beginner sewing enthusiast might start with a simple pattern kit to master basic stitching techniques before progressing to more intricate garment construction. In the realm of robotics, incrementally complex kits can guide users from fundamental wiring and programming to advanced sensor integration and autonomous navigation. The selection of a construction set should therefore be viewed as a strategic investment in personal growth, predicated on a realistic evaluation of current abilities and a clear understanding of learning objectives. Manufacturers cater to this requirement by labeling their offerings with recommended skill levels, categorizing sets by beginner, intermediate, and advanced classifications, thus facilitating informed purchase decisions.

In conclusion, the relationship between skill level and the suitability of a component-based construction set is a cornerstone of a positive and productive experience. The challenges arising from misalignment in this domain necessitate careful consideration and informed decision-making. Prioritizing this consideration ensures that the project serves as both a creative outlet and a vehicle for skill enhancement, ultimately aligning with the broader goals of personal development and intellectual enrichment.

4. Project purpose

The intended objective of a project directly influences the selection and utilization of a component-based construction set. The project’s specific requirements dictate the necessary components, complexity, and desired outcome. Understanding the purpose beforehand is paramount for ensuring project success and efficient resource allocation.

- Functional Application vs. Aesthetic Display

The intended use case of the finished project dictates the choice of component. A set designed for constructing a functional electronic device, such as an amplifier, prioritizes components with specific electrical characteristics and reliability. Conversely, a set for creating a decorative item, like a model ship, emphasizes aesthetic details and visual appeal. The selection criteria shift dramatically based on whether the final product is intended for practical application or solely for display.

- Educational Tool for Skill Development

Component-based sets can serve as valuable educational tools for skill development in various disciplines. A robotics kit, for example, can be used to teach programming, electronics, and mechanical engineering principles. The project’s purpose is explicitly educational, focusing on learning and experimentation rather than achieving a specific end product. This requires sets with clear instructions, modular components, and potential for iterative improvement and modification.

- Customization and Modification Potential

The degree to which a project is intended for customization significantly affects the choice of components and set design. A set intended for heavy modification necessitates readily available individual components, open-source design specifications, and ease of disassembly and reassembly. For example, sets for building custom 3D printers require a high degree of flexibility for adapting to diverse printing materials and configurations.

- Budgetary Constraints and Cost-Effectiveness

Financial limitations inevitably influence the selection of a component-based construction set. If cost-effectiveness is paramount, one might opt for sets with simpler designs and readily available, less expensive components. However, sacrificing component quality to meet budgetary constraints may ultimately compromise the project’s longevity or performance. A careful trade-off between cost and functionality is often necessary to align with the project’s budgetary purpose.

The various facets of project purpose underscore the critical importance of defining the desired outcome prior to selecting a component-based construction set. Whether for functional application, educational enrichment, customizable design, or budgetary compliance, aligning the kit’s capabilities with the project’s objective is crucial for optimizing the user experience and achieving the intended result. Without a clear understanding of the project’s aims, the choice of kit becomes arbitrary and the likelihood of success diminishes substantially.

5. Required tools

Successful utilization of component-based construction sets necessitates the availability of appropriate tools. The absence of essential implements can impede progress, compromise the quality of the final product, and potentially lead to damage or injury. Therefore, careful consideration of the required toolset is an integral aspect of project planning.

- Assembly and Fastening Implements

The proper assembly and secure fastening of compone

nts frequently require specialized tools. Screwdrivers of varying sizes and head types, wrenches, pliers, and clamps are often essential for joining parts and ensuring structural integrity. For example, assembling a wooden model kit may require clamps to hold pieces together while adhesive cures, while an electronics kit might necessitate specialized pliers for bending and cutting wire leads. Utilizing inadequate or inappropriate tools can lead to stripped screws, weakened joints, or damaged components. - Cutting and Shaping Instruments

Modifying or customizing components may necessitate the use of cutting and shaping instruments. Knives, saws, files, and sanding tools are commonly employed to refine dimensions, remove excess material, or create custom shapes. A plastic model kit may require a hobby knife for removing parts from the sprue and a file for smoothing edges, while a metalworking kit could involve the use of a saw for cutting metal sheets. The selection of appropriate cutting and shaping tools ensures precision and minimizes the risk of damage.

- Measuring and Alignment Devices

Precise measurements and accurate alignment are critical for many construction projects. Rulers, calipers, levels, and protractors are utilized to ensure correct dimensions, angles, and orientations. When building a multi-tiered structure, a level is essential for ensuring the stability and proper alignment of each layer. In electronics assembly, a multimeter is required to measure voltage, current, and resistance, ensuring that components are functioning within specified parameters. The use of measuring and alignment devices ensures accuracy and functional integrity.

- Soldering and Bonding Equipment

The permanent joining of components often requires soldering or bonding equipment. Soldering irons and solder are used to create electrical connections, while adhesives and glues are employed to bond non-metallic materials. An electronics kit invariably requires a soldering iron for connecting components to a circuit board, while a model airplane kit will typically include adhesive for assembling the airframe. Employing the appropriate soldering or bonding equipment ensures strong and reliable connections.

The tool requirements associated with a component-based construction set are therefore directly dependent on the project’s complexity, materials, and intended functionality. Proper tool selection and utilization are crucial for achieving a successful outcome, ensuring both the structural integrity and the aesthetic quality of the finished product.

6. Safety guidelines

Adherence to safety guidelines is paramount in the context of component-based construction sets, mitigating potential risks associated with tools, materials, and processes inherent in their use. Clear and comprehensive safety protocols are essential for minimizing the likelihood of injury or damage during assembly and operation.

- Material Handling and Exposure

Component-based sets often include materials that may pose health risks if mishandled. Adhesives may contain volatile organic compounds (VOCs), plastics can release fumes when heated, and certain metals may cause allergic reactions. Safety guidelines dictate appropriate ventilation, personal protective equipment (PPE) such as gloves and masks, and proper disposal procedures. Ignoring these precautions can lead to respiratory irritation, skin sensitization, or other adverse health effects.

- Tool Operation and Hazard Mitigation

Many sets require the use of tools that present inherent safety hazards. Cutting tools, soldering irons, and power tools all carry the risk of injury if used improperly. Safety guidelines emphasize the importance of proper tool handling techniques, the use of safety glasses or face shields, and the maintenance of a safe work environment. Failure to follow these guidelines can result in cuts, burns, electrical shocks, or other serious injuries.

- Electrical Safety and Circuit Protection

Sets involving electrical components pose a risk of electrical shock or fire if not handled correctly. Safety guidelines mandate the use of insulated tools, the proper grounding of equipment, and the adherence to voltage and current limitations. They also emphasize the importance of using protective devices such as fuses and circuit breakers to prevent overloads and short circuits. Ignoring these precautions can lead to electrical burns, shocks, or even fires.

- Age Appropriateness and Supervision

Component-based construction sets often contain small parts that can be choking hazards for young children, and complex projects that require mature judgment and dexterity. Safety guidelines specify the recommended age range for each set and emphasize the importance of adult supervision when children are involved. Failure to heed these warnings can result in accidental ingestion of small parts or injuries sustained during assembly.

The convergence of these safety facets underscores the necessity of integrating comprehensive safety information within component-based construction sets. Manufacturers bear a responsibility to provide clear and unambiguous safety guidelines, while users must prioritize adherence to these protocols to ensure a safe and enjoyable experience. The avoidance of negligence safeguards the well-being of individuals engaging in this activity.

Frequently Asked Questions About Component-Based Construction Sets

The following addresses prevalent inquiries and clarifies common misconceptions concerning component-based construction sets. The information presented aims to provide a comprehensive understanding of these sets, facilitating informed decisions and optimized utilization.

Question 1: What distinguishes a component-based construction set from a pre-assembled product?

A component-based construction set necessitates assembly, involving the manipulation and integration of individual parts to create a functional or decorative item. A pre-assembled product arrives fully constructed and ready for immediate use, eliminating the assembly process.

Question 2: What factors should be considered when selecting a construction set based on skill level?

The complexity of the set, the number of components, the intricacy of the assembly process, and the tools required all contribute to the overall skill level demanded. Beginners should opt for simplified sets with comprehensive instructions, while experienced individuals may seek more challenging projects.

Question 3: What are the potential benefits of engaging with a component-based construction set?

Potential benefits include the acquisition of new skills, enhanced problem-solving abilities, increased creativity, and a sense of accomplishment upon completion. Furthermore, these sets can foster an understanding of engineering principles and design concepts.

Question 4: How does component quality impact the overall outcome of a project?

The quality of the components directly influences the durability, functionality, and aesthetic appeal of the finished product. Inferior materials can compromise structural integrity, reduce performance, and diminish the overall value of the project.

Question 5: What safety precautions should be observed when working with construction sets involving tools or hazardous materials?

Adherence to manufacturer-provided safety guidelines i

s paramount. Appropriate personal protective equipment (PPE), such as gloves and eye protection, should be utilized. Adequate ventilation is necessary when working with adhesives or other volatile substances. Proper tool handling techniques must be followed to prevent injury.

Question 6: How can one ensure the successful completion of a component-based construction project?

Careful planning, meticulous execution, adherence to instructions, utilization of appropriate tools, and a commitment to safety are all essential for successful project completion. Patience and perseverance are also valuable attributes.

In summary, careful selection, mindful execution, and strict adherence to safety protocols are critical for maximizing the benefits and minimizing the risks associated with component-based construction sets.

The next section will explore specific applications of component-based construction sets across various industries and domains.

Component-Based Construction Sets

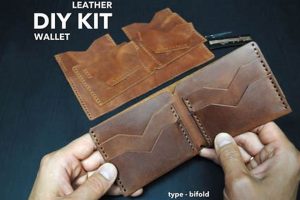

This exploration of component-based construction sets, frequently referred to as “DIY kit,” has underscored their multifaceted nature, extending beyond mere recreational activity to encompass educational opportunities, skill development, and practical applications. The discussion has emphasized the significance of component quality, instructional clarity, skill-level matching, intended purpose alignment, tool requirements, and unwavering adherence to safety guidelines.

The effective utilization of these resources hinges on a commitment to informed decision-making and diligent execution. As technology advances and societal demands evolve, the role of component-based construction sets in fostering innovation and problem-solving skills is likely to expand. Therefore, continued research and development in this domain are essential for maximizing their potential to contribute to personal growth and technological advancement.