The concept refers to creative projects involving the self-assembly of seating structures. These projects offer an alternative to purchasing pre-made furniture, allowing individuals to customize pieces to specific needs and aesthetic preferences. An example includes repurposing reclaimed wood into a garden seat or constructing an indoor settle from readily available materials.

Creating personalized seating has several advantages. Cost savings are often realized compared to buying manufactured items. Furthermore, the process facilitates resourcefulness by using recycled or upcycled materials. Historically, the creation of furnishings by individuals was a common practice, reflecting a resource-driven society and an emphasis on practical skills.

Subsequent sections will explore the different material options, construction techniques, and design considerations relevant to building personalized seating. Guidance on safety precautions and project planning will also be provided to ensure successful outcomes.

Essential Considerations for Personalized Seating Projects

Successful construction of personalized seating structures requires careful planning and execution. The following tips provide guidance on key aspects to ensure a durable and aesthetically pleasing result.

Tip 1: Material Selection is Critical: The choice of materials significantly affects longevity and style. Weather-resistant woods, such as cedar or redwood, are suitable for outdoor applications. Consider the structural properties and aesthetic qualities of each material before committing to a design.

Tip 2: Accurate Measurements are Essential: Prior to any cutting or assembly, precise measurements are paramount. Ensure that all dimensions are accurately recorded and double-checked. Discrepancies can lead to structural instability and aesthetic flaws.

Tip 3: Prioritize Structural Integrity: The primary function of a seat is to provide safe and stable support. Reinforce joints with appropriate hardware, such as screws, bolts, or wood glue. Failure to adequately secure the structure can result in collapse and potential injury.

Tip 4: Proper Finishing Enhances Durability: A protective finish safeguards against environmental damage. Apply sealant, paint, or stain to prolong the lifespan of the seating structure, especially for outdoor projects. Follow the manufacturer’s instructions for optimal application and drying times.

Tip 5: Ergonomics Improve Comfort: Consider the principles of ergonomics when designing the seating surface. Optimal height, depth, and angle contribute to comfort and prevent strain. Test different configurations to identify the most comfortable arrangement.

Tip 6: Tool Selection Matters: Employ appropriate tools for each stage of the project. Use sharp saws for clean cuts, sturdy drills for secure fastenings, and accurate measuring devices for precise dimensions. Invest in quality tools to improve efficiency and accuracy.

Tip 7: Safety Precautions are Paramount: Always wear appropriate safety gear, including eye protection and gloves. Be mindful of potential hazards when using power tools. A safe working environment minimizes the risk of accidents and injuries.

These considerations contribute to the successful construction of personalized seating. By adhering to these guidelines, individuals can create functional and aesthetically pleasing pieces that meet specific needs and preferences.

The final section will present concluding thoughts on the enduring appeal and practical application of creating personalized seating structures.

1. Material Durability

Material durability is a critical factor influencing the longevity and overall value of self-assembled seating structures. Selecting appropriate materials directly impacts the ability of a bench to withstand environmental stresses, usage demands, and potential wear and tear. This, in turn, affects the long-term cost-effectiveness and sustainability of a seating project.

- Resistance to Environmental Degradation

Material susceptibility to moisture, sunlight, and temperature fluctuations significantly impacts longevity. For outdoor seating, materials like treated lumber, redwood, cedar, or recycled plastic lumber offer superior resistance to rot, insect infestation, and UV degradation. Conversely, untreated softwoods will degrade rapidly when exposed to the elements, resulting in premature failure and requiring frequent replacement or repair. The choice of material directly dictates the maintenance schedule and lifespan of the bench.

- Load-Bearing Capacity and Structural Integrity

The ability of a material to bear weight without deformation or failure is paramount for safety and functionality. Hardwoods like oak or maple offer high load-bearing capacity, making them suitable for benches intended for heavy use or multiple occupants. Softer woods or composite materials may require reinforced construction or limited weight restrictions. The material’s tensile strength and resistance to bending are crucial considerations when designing the structural support system of the bench.

- Abrasion and Impact Resistance

Surface durability determines a material’s ability to withstand scratches, dents, and other forms of physical damage. Materials like concrete, stone, or hardwoods with a protective coating offer superior abrasion resistance, making them suitable for high-traffic areas or environments where the bench is likely to be subjected to rough use. Softer materials may require protective finishes or careful placement to minimize wear and tear. The material choice affects the aesthetic appearance and perceived quality of the bench over time.

- Maintenance Requirements and Life-Cycle Cost

The ease of cleaning, repair, and refinishing contributes to the overall life-cycle cost of a bench. Materials like plastic or metal require minimal maintenance, while wood may necessitate periodic sanding, staining, or sealing. The cost of maintenance should be factored into the initial material selection to ensure long-term affordability and sustainability. The availability of replacement parts or repair services also influences the long-term viability of the seating structure.

In summary, selecting materials based on their durability characteristics is essential for creating functional, safe, and aesthetically pleasing seating structures. By considering factors such as environmental resistance, load-bearing capacity, abrasion resistance, and maintenance requirements, individuals can optimize the lifespan and cost-effectiveness of their self-assembled seating projects, enhancing their value and sustainability.

2. Design Aesthetics

Design aesthetics significantly influences the perceived value and integration of self-assembled seating structures within

a given environment. The visual appeal and stylistic congruity of a bench contribute to its functional and decorative role. Considering design aesthetics ensures the finished product harmonizes with its surroundings and reflects the creator’s preferences.

- Form and Silhouette

The overall shape and outline define a bench’s visual impact. Clean, geometric forms can create a modern aesthetic, while curved or organic shapes evoke a more traditional or rustic feel. The silhouette should complement the existing architectural style or landscape design. For instance, a minimalist bench with straight lines would be suitable for a contemporary garden, whereas a curved bench with ornate details might better suit a Victorian-era porch. Successful integration requires careful consideration of the intended location and its existing aesthetic qualities.

- Material Palette and Texture

The selection of materials and their respective textures contributes significantly to the overall aesthetic. Natural materials like wood or stone offer warmth and tactile appeal, while metal or concrete can provide a sleek, industrial aesthetic. The color palette should harmonize with the surroundings, either blending in subtly or providing a contrasting focal point. For example, a bench made from reclaimed wood with a weathered finish can add character to a rustic outdoor space. Conversely, a brightly painted metal bench can inject a pop of color into a neutral urban setting. The interplay of materials and textures creates visual interest and enhances the aesthetic appeal.

- Details and Embellishments

Ornamental details and embellishments can elevate a bench’s aesthetic value and personalize its design. Carvings, inlays, or decorative hardware can add visual interest and reflect a specific style. However, excessive ornamentation can detract from the overall design and create a cluttered appearance. The key is to strike a balance between functionality and aesthetic expression. For example, simple geometric patterns carved into the backrest of a bench can add a touch of elegance without overwhelming the design. Thoughtful details contribute to the overall visual appeal and reflect the creator’s attention to craftsmanship.

- Proportion and Scale

The relative size and dimensions of the bench in relation to its surroundings are critical for achieving visual harmony. A bench that is too large can overwhelm a small space, while one that is too small can appear insignificant. The proportions of the bench itself, such as the height of the seat and the thickness of the legs, should also be carefully considered. For example, a low-slung bench can create a relaxed and inviting atmosphere in a garden setting. Proper scaling ensures that the bench is both functional and aesthetically pleasing within its context. Attention to proportion and scale is crucial for creating a visually balanced and harmonious design.

These facets collectively underscore the importance of design aesthetics in self-assembled seating projects. Through deliberate choices regarding form, materials, details, and scale, individuals can create benches that not only serve a practical purpose but also enhance the visual appeal of their surroundings. The successful integration of design aesthetics transforms a functional object into a decorative element that complements and elevates the overall environment.

3. Structural Stability

In the context of self-assembled seating, structural stability represents a foundational requirement. The ability of a bench to withstand applied loads without deformation or failure directly dictates its safety and service life. The causal relationship between design and construction techniques is significant: inadequate design or improper assembly inevitably leads to compromised stability. A poorly designed bench, regardless of aesthetic appeal, poses a safety hazard. For example, a bench constructed with insufficient support members or improperly joined connections can collapse under moderate weight, resulting in potential injury. Structural stability, therefore, is not merely a desirable attribute but a critical component of successful bench construction.

The implementation of sound engineering principles is essential for achieving adequate structural integrity. This includes calculating load-bearing requirements, selecting appropriate materials, and employing proper joinery techniques. Consider a simple wooden bench: the thickness and spacing of the legs, the type of wood used, and the method of attaching the seat to the frame all directly influence its stability. A design incorporating mortise and tenon joints, for instance, provides significantly greater strength and resistance to racking than a design relying solely on screws or nails. Similarly, using hardwoods rather than softwoods increases the bench’s ability to withstand weight and resist deformation over time. Real-world examples abound in public spaces, where professionally designed and constructed benches demonstrably withstand years of heavy use due to their inherent structural stability.

Understanding the principles of structural stability is of practical significance for individuals undertaking self-assembled seating projects. It empowers them to make informed decisions regarding design, material selection, and construction methods, thereby increasing the likelihood of creating safe, durable, and functional seating structures. While complex engineering calculations may not be feasible or necessary for every project, a basic understanding of load distribution, stress points, and material properties is crucial. Challenges in ensuring stability can arise from a lack of knowledge, improper tool usage, or the use of substandard materials. However, by prioritizing structural integrity and adhering to established construction practices, these challenges can be effectively mitigated, resulting in a successful and safe project outcome. In conclusion, structural stability is inextricably linked to the success of personalized seating projects, impacting both safety and long-term utility.

4. Ergonomic Comfort

Ergonomic comfort, in the context of self-assembled seating, constitutes a critical functional attribute directly influencing user experience and well-being. The design and construction of benches must prioritize ergonomic principles to ensure postural support, reduce strain, and promote sustained comfort during use. The absence of ergonomic considerations in seating design can lead to discomfort, fatigue, and potentially, musculoskeletal problems. This understanding underscores the importance of integrating ergonomic principles into every stage of bench design and construction. A direct consequence of neglecting ergonomics is reduced user satisfaction and limited usability of the finished product.

Practical application of ergonomic principles involves careful consideration of dimensions, angles, and materials. Seat height, depth, and backrest angle should be tailored to accommodate a range of users and promote proper posture. For example, a seat height that is too low can cause excessive knee flexion, while a backrest lacking sufficient lumbar support can contribute to lower back pain. Incorporating features such as contoured seats, armrests, and adjustable backrests can significantly enhance comfort. Material selection also plays a role; cushioned or padded surfaces offer greater comfort than hard, unyie

lding materials. The design of outdoor benches requires additional considerations, such as accommodating for variations in clothing thickness and providing adequate shade. Adherence to ergonomic guidelines ensures that the seating structure not only serves its functional purpose but also promotes user well-being and prevents discomfort-related issues.

In summary, ergonomic comfort is an indispensable component of successful seating projects. The integration of ergonomic principles into design and construction directly impacts user experience, safety, and long-term usability. Challenges in achieving optimal ergonomic comfort may arise from limited knowledge of ergonomic principles or constraints in material availability. However, by prioritizing ergonomic considerations and employing sound design practices, individuals can create seating structures that are both functional and conducive to user well-being, significantly enhancing the overall value and appeal of their creations.

5. Cost Effectiveness

Cost effectiveness constitutes a primary driver for many individuals engaging in self-assembled seating projects. The potential for significant savings compared to purchasing commercially manufactured benches is a substantial incentive. This economic consideration necessitates a detailed examination of the various facets influencing the overall cost of a DIY bench.

- Material Acquisition Strategies

The method of material procurement directly impacts the overall cost. Utilizing reclaimed or recycled materials, such as salvaged lumber or repurposed metal components, can substantially reduce expenses compared to purchasing new materials. For example, a bench constructed from reclaimed pallet wood often costs significantly less than a similar bench built with newly purchased lumber. However, the trade-off may involve increased labor for cleaning, preparing, and modifying reclaimed materials. Sourcing materials from local suppliers or salvage yards may also yield cost savings by minimizing transportation expenses and potentially accessing discounted rates.

- Labor and Skill Investment

While DIY projects eliminate direct labor costs in the form of paid wages, they require a significant investment of personal time and skill. The complexity of the bench design and the builder’s proficiency directly impact the amount of time required for completion. A simple, straightforward design requiring basic carpentry skills will generally be more cost-effective than an elaborate design demanding advanced techniques and specialized tools. The opportunity cost of time spent on the project should also be considered; individuals should assess whether their time could be more profitably employed in other endeavors. Moreover, potential costs associated with errors or rework due to lack of skill should be factored into the overall assessment.

- Tool and Equipment Requirements

The tools and equipment necessary for constructing a bench can represent a significant initial investment. While basic tools, such as a saw, drill, and measuring devices, are often readily available, more complex designs may necessitate specialized tools, such as a miter saw, planer, or jointer. Renting or borrowing tools can mitigate upfront costs, but prolonged rental periods can ultimately prove more expensive than purchasing the equipment outright. The long-term value and utility of the tools should be considered; if the tools will be used for multiple projects, the initial investment may be justified. Moreover, safety equipment, such as eye protection and gloves, should be included in the cost assessment.

- Design Complexity and Material Optimization

The complexity of the bench design directly influences material consumption and waste. Simple, minimalist designs generally require less material than ornate or elaborate designs. Careful planning and precise measurements can minimize material waste, further reducing costs. Optimizing material usage also involves selecting materials that are readily available in standard sizes and minimizing the need for custom cuts. For example, designing a bench using standard lumber dimensions can reduce waste and simplify construction. Additionally, utilizing readily available fasteners and hardware can help minimize costs and streamline the assembly process.

In conclusion, achieving cost effectiveness in self-assembled seating projects requires a holistic approach that considers material acquisition, labor investment, tool requirements, and design optimization. By carefully evaluating these factors and making informed decisions, individuals can effectively minimize expenses and maximize the value derived from their DIY bench projects. The economic benefits, coupled with the potential for customization and creative expression, contribute to the enduring appeal of self-assembled seating solutions.

6. Space Optimization

Space optimization, when integrated into the design and construction of self-assembled seating, directly addresses the efficient utilization of available area. The principles of spatial economy are particularly relevant in constrained environments, where multifunctional furniture solutions are essential for maximizing usability.

- Multifunctional Designs

Multifunctional benches serve dual purposes, integrating seating with storage or convertible surfaces. Examples include benches with built-in drawers, lift-up seats revealing hidden compartments, or designs that transform into tables. In small apartments or entryways, such benches reduce clutter and maximize utility. A storage bench in a hallway provides seating for putting on shoes while simultaneously offering storage for seasonal items.

- Foldable and Modular Configurations

Foldable or modular seating allows for adaptable use of space. Folding benches can be stowed away when not needed, freeing up floor space. Modular designs allow for rearrangement and reconfiguration to suit different activities or gatherings. Consider a folding bench mounted on a wall in a workshop, which can be deployed for temporary seating and then folded away to maximize work area.

- Corner and Niche Integration

Custom-built benches can effectively utilize awkward or underutilized spaces such as corners, alcoves, or niches. These designs maximize seating capacity within the existing architectural framework. A corner bench in a breakfast nook provides seating without obstructing traffic flow. These solutions are particularly valuable in older homes with irregular layouts.

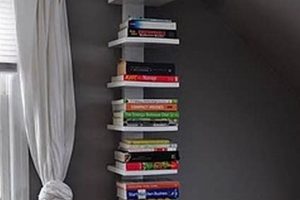

- Vertical Space Utilization

Extending bench designs vertically incorporates shelving or storage above the seating surface. This strategy maximizes the use of vertical space, providing additional storage without increasing the footprint of the bench. An example is a bench with integrated bookshelves in a reading nook, combining seating with readily accessible book storage.

These strategies for space optimization, when thoughtfully implemented in self-assembled seating projects, contribute to the creation of efficient, functional, and aesthetically pleasing environments. The combination of customized design and spatial awareness enhances the value of handcrafted seating solutions, particularly in space-limited settings.

7. Skill level

Proficiency directly influences the feasibility and outcome of self-assembled seating endeavors. The requisite expertise dictates design complexity, construction methods, and the selection of appropriate materials. Discrepancies between project demands and individual capabilities can lead to compromised structural integrity, aesthetic deficiencies, and project abandonment.

- Design Complexity and Execution

Intricate designs involving complex joinery or unconventional materials demand advanced carpentry skills. Attempting such projects without adequate experience increases the risk of errors, material waste, and structural instability. A novice might successfully construct a simple, straight-legged bench, while a seasoned woodworker could execute a curved, cantilevered design. The initial project selection should align with demonstrable abilities to ensure successful completion.

- Tool Proficiency and Safety

Operating power tools and hand tools safely and effectively necessitates training and experience. Improper tool usage increases the risk of personal injury and damage to materials. Skill level dictates tool selection and application; a beginner might rely on hand tools for controlled precision, whereas an expert may efficiently utilize power tools. Understanding tool limitations and safety protocols is paramount, irrespective of project complexity.

- Material Handling and Joinery Techniques

Different materials require specific handling techniques and joinery methods. Working with hardwoods necessitates precise cutting and fastening, while working with metals requires welding or specialized connectors. Skill level determines the appropriate joinery technique; a simple butt joint may suffice for a basic bench, while a mortise and tenon joint offers superior strength for demanding applications. Mastering these techniques requires practice and familiarity with material properties.

- Problem-Solving and Adaptability

Unforeseen challenges invariably arise during construction. The ability to troubleshoot issues, adapt to unexpected material variations, and modify the design as needed depends on experience and problem-solving skills. Skill level influences the approach to overcoming obstacles; a novice may require guidance from external sources, while an experienced builder can devise innovative solutions. Adaptability is crucial for ensuring project completion despite unforeseen circumstances.

The interplay between proficiency and project demands is paramount. Selecting bench designs commensurate with existing abilities, investing in skill development, and prioritizing safety measures enhance the likelihood of successful and rewarding self-assembled seating experiences. The realistic assessment of capabilities mitigates potential frustrations and promotes the creation of functional and aesthetically pleasing seating structures.

Frequently Asked Questions

The following addresses commonly encountered inquiries regarding the design, construction, and maintenance of personalized seating.

Question 1: What are the primary factors influencing the structural integrity of a self-assembled bench?

Structural integrity is primarily determined by material selection, joint construction, and load distribution. Appropriate materials with sufficient load-bearing capacity must be chosen. Joints should be designed and executed to withstand anticipated stresses. Load should be distributed evenly across the support structure to prevent localized failure.

Question 2: How does one minimize material waste when undertaking a bench construction project?

Material waste can be minimized through meticulous planning and precise measurements. A detailed cutting list should be created before commencing any cutting operations. Designs should be optimized to utilize standard material dimensions, reducing the need for excessive trimming. Reclaimed materials should be carefully inspected and strategically incorporated to minimize unusable portions.

Question 3: What are the key considerations when selecting wood for outdoor bench construction?

Durability and resistance to environmental degradation are paramount. Weather-resistant species, such as cedar, redwood, or treated lumber, should be prioritized. The wood should be properly seasoned and treated with a protective finish to prevent rot, insect infestation, and UV damage. Consideration should be given to the wood’s structural properties and aesthetic qualities.

Question 4: How can one ensure ergonomic comfort in a self-assembled bench design?

Ergonomic considerations involve optimizing seat height, depth, and backrest angle. Seat height should allow for comfortable leg positioning. Seat depth should provide adequate thigh support. Backrests should offer lumbar support to promote proper posture. The inclusion of armrests can further enhance comfort.

Question 5: What are the essential safety precautions to observe when using power tools for bench construction?

Appropriate safety gear, including eye protection, hearing protection, and gloves, should always be worn. Power tools should be used in accordance with manufacturer’s instructions. The work area should be well-lit and free of obstructions. Before operating any power tool, ensure that all safety guards are in place and functioning correctly. Never operate power tools when fatigued or under the influence of impairing substances.

Question 6: How should a self-assembled bench be maintained to prolong its lifespan?

Regular cleaning and inspection are essential. Dirt and debris should be removed to prevent the accumulation of moisture and the growth of mold or mildew. Protective finishes should be reapplied periodically to maintain weather resistance. Loose fasteners should be tightened to prevent structural instability. Damaged components should be repaired or replaced promptly to prevent further deterioration.

The above provides essential guidance for navigating the complexities of building personalized seating. Careful consideration of these aspects enhances project success.

The subsequent section explores advanced bench construction techniques.

Conclusion

This exploration of bench diy ideas has underscored the multifaceted nature of creating personalized seating. From material selection and structural integrity to ergonomic considerations and cost-effectiveness, numerous factors influence project success. Careful planning, skill development, and adherence to established construction practices are paramount for achieving desired outcomes.

The act of constructing personalized seating represents more than mere assembly; it embodies resourcefulness, creative expression, and a commitment to functional design. Individuals are encouraged to approach these endeavors with diligence and a focus on safety, ultimately contributing to the creation of durable and aesthetically pleasing additions to their living spaces.