The construction of customized, low-profile furniture utilizing a cementitious mixture offers a unique blend of industrial aesthetics and personalized design. This involves employing basic construction techniques to shape and cure a durable surface suitable for supporting various objects in a living space, thereby serving as a functional and decorative element. For instance, an individual might construct a support structure from wood or metal and then pour a precisely formulated cement mixture into a mold atop it to create a surface that can withstand regular use.

Its appeal stems from the combination of cost-effectiveness, design flexibility, and the creation of a robust and visually striking piece of furniture. Historically, concrete has been relegated to structural applications, but contemporary design trends embrace its raw texture and inherent strength. Utilizing this material allows individuals to create furniture that is both modern and enduring, reflecting a minimalist or industrial style while offering a tangible sense of accomplishment in crafting a bespoke home furnishing.

The ensuing discussion will delve into the specifics of material selection, mold construction, mixing and pouring techniques, finishing processes, and design considerations necessary for the successful fabrication of this unique furnishing. Detailed explanations and practical guidance will be provided to ensure a positive and durable outcome for any enthusiast undertaking this project.

Essential Considerations for Concrete Table Construction

Achieving a successful outcome in crafting a cement-based table requires careful planning and execution. Attention to detail throughout the process is crucial for ensuring both structural integrity and aesthetic appeal.

Tip 1: Mold Integrity: Prioritize the construction of a structurally sound mold. Any imperfections or weaknesses in the mold will directly translate to flaws in the final cast. Use robust materials and secure joinery to prevent leakage or deformation during the pour.

Tip 2: Mixture Proportions: Adhere to precise mixture ratios of cement, aggregates, and water. Deviations from recommended proportions can compromise the concrete’s strength and durability, leading to cracking or premature deterioration. Consider the addition of plasticizers to improve workability and reduce water content.

Tip 3: Reinforcement Integration: Incorporate appropriate reinforcement, such as wire mesh or rebar, particularly for larger table surfaces. Reinforcement enhances tensile strength and minimizes the risk of cracking under stress. Ensure proper placement within the concrete matrix to maximize its effectiveness.

Tip 4: Pouring Technique: Employ a consistent pouring technique to minimize air entrapment. Vibration or tapping the mold during pouring helps to consolidate the concrete and release trapped air bubbles, resulting in a smoother, more uniform surface. Pouring in layers can also help minimize air pockets.

Tip 5: Curing Process: Maintain optimal curing conditions for a minimum of seven days. Keep the concrete moist by covering it with plastic sheeting or spraying it with water regularly. Proper curing promotes hydration and strengthens the cement matrix, resulting in increased durability and reduced shrinkage cracking.

Tip 6: Surface Finishing: Select appropriate finishing techniques to achieve the desired aesthetic. Grinding, polishing, or sealing can enhance the surface’s smoothness, color, and resistance to staining. Experiment with different finishes on test samples to determine the most suitable option.

Tip 7: Sealing Application: Apply a high-quality sealant to protect the finished surface from moisture and stains. Select a sealant specifically designed for concrete surfaces and follow the manufacturer’s instructions carefully. Regular resealing may be necessary to maintain optimal protection.

Adherence to these guidelines contributes significantly to the creation of a durable and visually appealing surface. Proper material selection, meticulous execution, and attention to detail are paramount for long-term success.

The subsequent sections will address specific design considerations and aesthetic enhancements for achieving a personalized and visually striking cement-based furnishing.

1. Material Selection

Material selection forms the bedrock of a successful cement-based furniture endeavor. The properties of chosen components directly impact the final product’s structural integrity, aesthetic qualities, and longevity. Informed decisions regarding cement type, aggregates, and admixtures are therefore paramount.

- Cement Type

The selection of cement significantly influences the setting time, strength development, and color of the final piece. Portland cement, available in various types, is a common choice, but specialized options like white cement can be used for aesthetic considerations. Rapid-setting cements can accelerate the project timeline, while low-shrinkage options mitigate cracking risks. The intended application and desired finish should guide the selection of cement type.

- Aggregate Selection

Aggregates, such as sand and gravel, constitute a significant portion of the cement mixture and impact workability, strength, and surface texture. The gradation and size distribution of aggregates affect the concrete’s density and porosity. Fine aggregates contribute to a smooth surface finish, while coarser aggregates enhance structural strength. Careful selection of aggregate types is crucial for achieving the desired balance between workability, strength, and aesthetic appeal.

- Admixtures and Additives

Admixtures and additives modify the properties of the concrete mixture, enhancing workability, durability, and aesthetic characteristics. Plasticizers improve the flowability of the concrete, reducing the water-to-cement ratio and increasing strength. Pigments can be added to create colored concrete, while fiber reinforcement enhances tensile strength and reduces cracking. The incorporation of appropriate admixtures and additives allows for fine-tuning the concrete’s properties to meet specific project requirements.

- Reinforcement Materials

While not strictly part of the “mixture,” reinforcement materials are essential to consider during material selection. Options such as steel rebar or wire mesh provide tensile strength to resist cracking and deformation. Proper selection of reinforcement materials and ensuring adequate coverage within the cement matrix is crucial for the structural stability and longevity of the finished table, particularly for larger surfaces or designs with significant spans.

The convergence of these material selection choices dictates the overall success of the cement-based furniture creation. Careful evaluation of each component’s role and influence, coupled with thoughtful planning, ensures a durable, aesthetically pleasing, and structurally sound final product. Substituting readily available materials without considering their properties can compromise the outcome.

2. Mold Construction

Mold construction is a critical phase in the fabrication of cement-based low tables. The mold dictates the final dimensions, shape, and surface finish of the piece. Accuracy and structural integrity of the mold are therefore paramount for achieving the desired aesthetic and functional outcome. This phase requires careful planning, precise execution, and appropriate material selection to ensure a successful casting process.

- Material Selection for Mold Construction

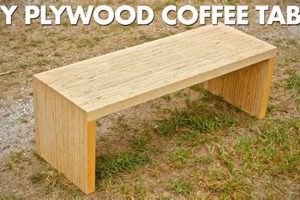

The choice of mold material significantly influences the ease of construction, demolding process, and the achievable surface finish of the cast. Common materials include plywood, melamine-laminated particleboard, and silicone. Plywood offers structural rigidity but requires careful sealing to prevent moisture absorption. Melamine provides a smooth, non-porous surface, facilitating easy demolding. Silicone is suitable for creating complex shapes and textures but may require external support to maintain its form. The selection should balance cost, availability, ease of use, and the desired surface characteristics.

- Structural Integrity and Reinforcement

The mold must withstand the hydrostatic pressure exerted by the wet concrete. Insufficient reinforcement or weak joints can lead to deformation or failure during the pour, resulting in dimensional inaccuracies or structural defects in the final table. External bracing, such as wood frames or metal supports, may be necessary, particularly for larger or more complex mold designs. Adequate reinforcement ensures that the mold maintains its shape and prevents unwanted bulging or warping during the casting process.

- Sealing and Release Agents

Effective sealing of the mold interior prevents water absorption from the concrete mixture, which can weaken the concrete and make demolding difficult. Applying a release agent, such as form oil or a specialized concrete release compound, further facilitates demolding and prevents damage to the cast surface. Thorough sealing and the use of release agents are essential for achieving a smooth, defect-free surface and simplifying the removal of the finished table from the mold.

- Dimensional Accuracy and Design Considerations

The dimensions of the mold must precisely match the desired dimensions of the finished surface. Any discrepancies or inaccuracies in the mold will be directly reflected in the final product. Proper planning, accurate measurements, and careful construction techniques are essential for achieving the intended design. Complex shapes or intricate details require more elaborate mold designs and may necessitate the use of specialized techniques, such as creating molds in multiple sections or incorporating removable inserts.

The successful fabrication of a cement-based low table hinges on the meticulous construction of a robust and accurate mold. A well-designed and constructed mold ensures dimensional accuracy, prevents structural defects, and facilitates easy demolding, ultimately contributing to a high-quality finished product. The time and effort invested in proper mold construction are directly reflected in the aesthetic appeal and structural integrity of the final piece of furniture.

3. Mixing Ratios

The proportioning of constituent materials within a cementitious mixture is a fundamental determinant of the resulting composite’s properties, particularly in the context of crafting a bespoke surface. Precise control over these ratios directly influences the structural integrity, aesthetic outcome, and long-term durability of the piece.

- Water-to-Cement Ratio (w/c)

The water-to-cement ratio is arguably the most critical factor governing concrete strength. A lower w/c ratio yields a denser, stronger matrix with reduced permeability, leading to enhanced durability. However, excessively low w/c ratios can compromise workability, making the mixture difficult to pour and consolidate. For a low profile surface, a balance must be struck to achieve both sufficient strength and manageable workability. Ratios typically range from 0.4 to 0.5, adjusted based on specific cement type and aggregate characteristics. Improper w/c ratios can manifest as cracking, reduced compressive strength, and increased susceptibility to freeze-thaw damage.

- Aggregate-to-Cement Ratio (a/c)

The aggregate-to-cement ratio dictates the volume fraction of aggregates within the mixture, influencing its cost, workability, and thermal properties. A higher a/c ratio generally reduces cost but can also compromise workability and increase shrinkage. Conversely, a lower a/c ratio enhances workability and reduces shrinkage but increases cost. For a durable surface, a balanced a/c ratio is essential. Typically ratios range from 2:1 to 4:1, adjusted based on aggregate size, gradation, and cement type. Imbalances in this ratio can lead to segregation, bleeding, and reduced flexural strength.

- Admixture Dosage

Admixtures, such as plasticizers, retarders, and accelerators, are added in relatively small quantities but exert a significant influence on the concrete’s properties. Plasticizers improve workability, allowing for reduced water content and increased strength. Retarders delay setting time, useful in hot weather applications or for complex pours. Accelerators accelerate setting time, beneficial in cold weather. Accurate dosage is crucial; overdosing or underdosing can have detrimental effects on the final product’s performance. Manufacturers’ recommendations should be strictly adhered to. Improper admixture dosage can lead to inconsistent setting times, reduced strength gain, and surface defects.

- Pigment Proportion

When incorporating integral color into the concrete, the proportion of pigment must be carefully controlled to achieve the desired aesthetic outcome without compromising structural integrity. Excessive pigment can weaken the cement matrix and increase permeability. Pigment dosage should be kept to a minimum, typically not exceeding 5% by weight of cement. Thorough mixing is essential to ensure uniform color distribution. Variations in pigment proportion can result in inconsistent color, streaking, and reduced strength.

The careful consideration and precise execution of mixing ratios are paramount in crafting a robust and aesthetically pleasing low-profile surface. Deviations from recommended proportions can lead to structural deficiencies, aesthetic imperfections, and reduced longevity. A thorough understanding of the interplay between constituent materials and their respective proportions is essential for achieving a successful outcome. The implementation of test batches to verify desired characteristics prior to the final pour is highly recommended.

4. Reinforcement Placement

Reinforcement placement is intrinsically linked to the structural integrity and longevity of cement-based surfaces. The strategic positioning of reinforcing materials, such as wire mesh or rebar, within the concrete matrix directly counteracts tensile stresses, mitigating cracking and deformation, particularly in thin or expansive surfaces. Without adequate reinforcement, a self-made surface is susceptible to cracking under its own weight or when subjected to external loads. This effect is magnified in surfaces with minimal support or significant overhangs. The placement, type, and quantity of reinforcement must be carefully calculated based on the dimensions, shape, and intended use of the finished furniture. For example, a large surface area would require more substantial reinforcement compared to a smaller, simpler design. An inadequately reinforced surface is likely to exhibit cracking patterns, compromising its structural integrity and aesthetic appeal, thus rendering the entire construction effort futile.

Effective reinforcement placement requires considering the anticipated stress distribution within the structure. Reinforcement should be concentrated in areas of high tensile stress, typically near the edges and corners. Furthermore, the reinforcement must be adequately embedded within the concrete matrix to ensure proper bonding and stress transfer. Insufficient concrete cover over the reinforcement can lead to corrosion, weakening the reinforcement and ultimately compromising the surface’s structural integrity. In practical terms, this may involve suspending the reinforcement within the mold during the pouring process, ensuring that it is fully encapsulated by the cement mixture. Specialized spacers may be used to maintain the correct position of the reinforcement during pouring and curing. Examples include using epoxy-coated rebar for increased corrosion resistance in damp environments, or employing multiple layers of wire mesh for increased crack resistance in large flat surfaces.

In conclusion, the correct placement and utilization of reinforcement materials are indispensable for crafting durable and visually appealing cement-based surfaces. Neglecting this aspect can result in structural failure and aesthetic degradation, negating the time and resources invested in the project. Understanding the principles of stress distribution and reinforcement mechanics is critical for ensuring the long-term performance and stability of a do-it-yourself furniture construction. Challenges associated with reinforcement placement often stem from inadequate planning or a lack of understanding of the underlying principles. Proper planning and careful execution are crucial for achieving a successful and lasting result, emphasizing the importance of reinforcement as a vital component of any attempt.

5. Curing Process

The curing process is a critical stage in the creation of durable cement-based furniture, directly influencing the final strength, durability, and resistance to cracking of the material. Hydration, the chemical reaction between cement and water, requires a moist environment and a controlled temperature to proceed optimally. Premature drying prevents complete hydration, resulting in a weaker, more porous material prone to cracking and degradation. The duration of the curing period is dependent on factors such as cement type, ambient temperature, and humidity. For instance, a surface created with ordinary Portland cement typically requires a minimum curing period of seven days, whereas surfaces employing rapid-setting cements may require a shorter timeframe. Insufficient curing is a prevalent cause of failure in do-it-yourself concrete projects, often manifesting as surface cracking or reduced load-bearing capacity.

Practical methods for maintaining optimal curing conditions include covering the cast surface with plastic sheeting to retain moisture, regularly misting the surface with water, or employing a curing compound that seals the surface and prevents evaporation. The selection of an appropriate curing method depends on the size and complexity of the cast, as well as the prevailing environmental conditions. In warm or arid climates, more aggressive curing techniques may be necessary to compensate for increased evaporation rates. Furthermore, temperature fluctuations during the curing period can induce thermal stresses, potentially leading to cracking. Maintaining a stable temperature is therefore essential for preventing such issues. For example, one might use insulated blankets to protect the setting material from extreme temperature swings, especially in regions prone to such conditions.

In summary, the curing process is an indispensable component in the successful fabrication of long-lasting cement-based furniture. Implementing appropriate curing techniques is crucial for ensuring complete hydration, minimizing cracking, and maximizing the structural integrity of the final product. Understanding the underlying principles of cement hydration and the factors influencing its rate allows the fabricator to tailor the curing process to the specific requirements of each project, mitigating the risk of failure and ensuring a durable, aesthetically pleasing outcome. This stage demands careful attention and adherence to established best practices, as it fundamentally determines the performance and longevity of the self-constructed furniture. For a table to withstand the rigors of daily use, proper curing must be prioritized.

6. Surface Finishing

Surface finishing represents a critical phase in the construction of do-it-yourself cement-based low tables, directly influencing the aesthetic appeal, functionality, and long-term durability of the finished piece. The application of various techniques, such as grinding, polishing, sealing, and staining, transforms the raw, often porous concrete surface into a refined and usable tabletop. Without proper surface finishing, the concrete remains vulnerable to staining, scratching, and moisture absorption, compromising its longevity and visual appeal. A rough, unfinished surface, for instance, would be unsuitable for daily use, accumulating dirt and proving difficult to clean. Surface finishing, therefore, is not merely an aesthetic consideration but a functional necessity for creating a serviceable and enduring table.

The choice of surface finishing techniques depends on the desired aesthetic and the intended use of the low table. Grinding and polishing create a smooth, refined surface, highlighting the natural variations in the concrete aggregate. Sealing protects the surface from stains and moisture penetration, while staining can enhance the color and add depth to the concrete. For example, a table intended for outdoor use requires a more robust sealant to withstand the elements, while a table designed for indoor use may prioritize a high-gloss polished finish. Improper sealing can lead to water damage and staining, necessitating costly repairs or replacement. Careful selection and application of appropriate finishing techniques are therefore crucial for achieving the desired aesthetic and ensuring the long-term performance of the furniture. Consider the use of a penetrating sealant on concrete, or the application of epoxy coatings to ensure waterproofing.

In summary, surface finishing is an indispensable step in the creation of durable and aesthetically pleasing cement-based low tables. It addresses both functional and aesthetic considerations, transforming a raw material into a refined and usable piece of furniture. Neglecting this phase can result in a surface that is vulnerable to damage, difficult to maintain, and visually unappealing, undermining the entire construction effort. Understanding the various surface finishing techniques and their respective benefits allows the craftsman to create a customized and long-lasting table that meets specific needs and aesthetic preferences, contributing significantly to the overall success of the project. Without finishing, the raw material is simply not fit for purpose.

Frequently Asked Questions

The following addresses common inquiries regarding the construction and maintenance of customized low tables using cementitious materials. These questions are designed to clarify misconceptions and provide practical guidance for successful implementation.

Question 1: Is specialized expertise required to construct a cement-based low table?

While prior experience with concrete work is beneficial, it is not strictly necessary. However, a thorough understanding of fundamental construction techniques, including mold construction, mixing procedures, and curing protocols, is essential. Novices should begin with smaller, simpler projects to develop proficiency before tackling more complex designs. Safety precautions when handling cement and power tools must be strictly adhered to.

Question 2: What is the optimal thickness for a low surface?

The appropriate thickness depends on the size and design of the table, as well as the intended load-bearing capacity. A minimum thickness of two inches is generally recommended for adequate structural integrity. Larger surfaces or those intended to support heavy objects may require increased thickness and reinforcement. Overly thin surfaces are prone to cracking and failure. Consultation with structural engineering resources may be necessary for complex designs.

Question 3: How can cracking be prevented in cement-based surfaces?

Cracking can be minimized through proper mixture proportioning, reinforcement placement, and curing practices. Maintaining a low water-to-cement ratio, incorporating adequate reinforcement, and ensuring proper hydration during the curing process are crucial steps. The use of shrinkage-reducing admixtures can also help to mitigate cracking risks. Rapid temperature changes during curing should be avoided.

Question 4: What type of sealant is most suitable for protecting cement-based surfaces?

The selection of a sealant depends on the intended use and exposure conditions. Penetrating sealants are effective at preventing water and oil absorption, while film-forming sealants provide a protective layer on the surface. For outdoor applications, sealants with UV resistance are recommended. Epoxy sealants offer excellent durability and resistance to chemicals. The manufacturer’s instructions for application and maintenance should be carefully followed.

Question 5: How can a smooth surface finish be achieved?

A smooth surface finish can be achieved through careful mold preparation, proper pouring techniques, and subsequent grinding and polishing. Molds should be constructed from smooth, non-porous materials and thoroughly sealed. Vibration during pouring helps to consolidate the concrete and eliminate air pockets. Grinding and polishing with progressively finer grits can create a smooth, refined surface. The use of a concrete densifier can further enhance the surface hardness and reduce porosity.

Question 6: What are the long-term maintenance requirements for a cement-based low table?

Long-term maintenance involves regular cleaning with a mild detergent and periodic resealing to protect the surface from stains and moisture. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the sealant. Promptly wiping up spills prevents staining. Depending on usage and environmental conditions, resealing may be required every one to two years. Inspect the surface regularly for cracks or damage, and address any issues promptly to prevent further deterioration.

These answers provide a foundation for understanding the fundamental principles and best practices associated with constructing durable and aesthetically pleasing cement-based furniture. Diligent adherence to these guidelines will increase the likelihood of a successful outcome.

The subsequent section will explore advanced design considerations and decorative techniques for enhancing the visual appeal of cement-based furniture.

Conclusion

This exploration of constructing cement-based surfaces has underscored the critical aspects of material selection, mold fabrication, precise mixing, reinforcement integration, controlled curing, and surface finishing. The inherent challenges and potential rewards associated with each stage demand meticulous planning and execution. Success hinges upon a comprehensive understanding of the material properties, construction techniques, and environmental factors that influence the final product’s structural integrity and aesthetic appeal. A cement-based surface represents a confluence of form and function, requiring a deliberate approach to ensure both longevity and visual satisfaction.

Given the inherent complexities involved, prospective fabricators are encouraged to prioritize thorough research, practical experimentation, and adherence to established best practices. The creation of a durable and aesthetically pleasing cement-based low table represents a significant undertaking. With dedication and attention to detail, this endeavor can yield a unique and enduring piece of furniture, adding both value and character to its environment.